-

Produkte

-

Toepassing

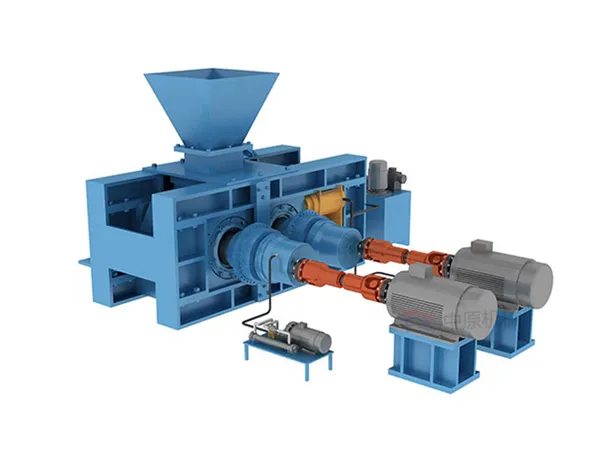

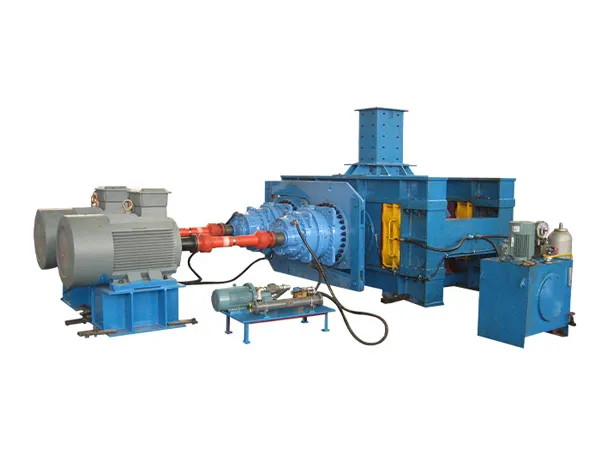

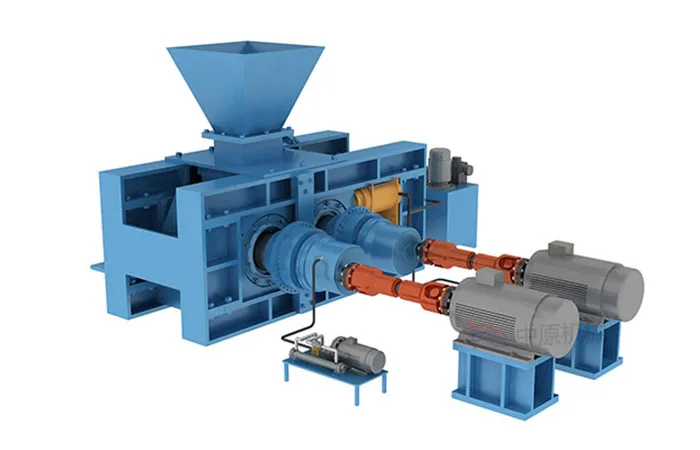

Imiqulu yokugaya enengcindezi ephezulu yakhiwe ngama-roller amabili, eyodwa yawo engaguquki futhi enye ingakwazi ukuslayida ngokuvundlile. Izinto ezibonakalayo zondliwa ngokuqhubekayo kusukela phezulu futhi zidlula igebe phakathi kwama-roller. I-roller ehambayo icindezelwa ukucindezela kwe-hydraulic, izinto ezibonakalayo zichotshozwa ukucindezela, futhi zicindezelwe zibe amakhekhe bese ziwa emshinini.

Imiqulu yokugaya enengcindezi ephezulu ingase ihlangabezane nezinhlobonhlobo zamaphutha avamile ngesikhathi sokusebenza. Lawa maphutha nezisombululo zawo kungafingqwa kanje:

1. Ukudlidliza okungavamile

Iphutha libangela:

Usayizi wezinto ezingalingani: Usayizi wempahla ongalingani uzobangela amandla okukhipha impahla ukuthi angalingani, okubangele ukudlidliza.

Ukuguga okukhulu kwe-scraper: I-scraper ayikwazi ukufosholo ngempumelelo impahla ngemuva kokugqoka, okubangela ukuthi i-roller icindezele okokusebenza ngezinye izikhathi futhi ngezinye izikhathi hhayi, okubangela ukudlidliza.

Izinto eziqinile kakhulu: Izinto eziqine kakhulu zingabangela ukuguga nokuguga kwerola yokugaya kanye nendandatho yokugaya, ngaleyo ndlela kubangele ukudlidliza.

Inkinga yabalandeli: Ama-fan blades of the high-pressure suspended grinding fan fan aqongelela impushana eningi noma ukuguga, okubangela ukuzungezisa okungenakulinganisela kwama-fan blades.

Amabhawodi okusetshenzwa kulengwa axegayo: Ngemva kokuthi okokusebenza sekusetshenziswe isikhathi esithile, amabhawodi okusetshenzwa kulengwa angase axege ngenxa yokudlidliza noma izizathu zokufakwa.

Isixazululo:

Lungisa usayizi wezinhlayiyana zento bese uzama ukuyenza ifane.

Hlola njalo futhi ubuyisele ama-scrapers agugile.

Gwema ukucutshungulwa kwezinto eziqinile kakhulu, hlola njalo futhi ubeke amarola okugaya namasongo okugaya, futhi ukhiphe izinsalela zensimbi ezintweni.

Susa impushana enqwabelene kuma-fan blades ngesikhathi, futhi uyishintshe ngesikhathi uma isigqokile.

Naka ukuqina kwamabhawodi okusetshenzwa kulengwa ngesikhathi sokulungiswa kwansuku zonke. Ziqinise ngesikhathi uma zixega.

2. Inkinga yokukhishwa kwempushana

Imbangela yokwehluleka:

Ukugqokwa kwensingo yefosholo: Ukugqokwa kwensingo yefosholo kuholela ekuphumeni okuncishisiwe kwempushana.

I-powder lock ayilungiswanga kahle: Isivalo se-powder lock asiqinile, okuholela ekumunceni okuyimpushana emuva.

Isixazululo:

Hlola futhi ubuyisele izindwani zamafosholo ezigugile njalo.

Misa umshini ukuze uhlole futhi ulungise uphawu lwe-powder lock, futhi uvale ukuvuza komoya.

3. Iqedile inkinga yosayizi wezinhlayiyana zomkhiqizo

Imbangela yokwehluleka:

Ukulungiswa okungalungile kwevolumu yomoya wabalandeli.

Ama-analyzer blades ayagqokwa.

Isixazululo:

Lungisa ivolumu yomoya ngokuya ngokumahhadla kwempahla ekhishiwe. Uma i-coarse kakhulu, lungisa ivolumu yomoya ibe yinani elincane, futhi uma inhle kakhulu, lungisa ivolumu yomoya ibe yisamba esikhulu.

Shintsha ama-analyzer agugile ngesikhathi.

4. Inkinga yezimoto

Imbangela yokwehluleka:

Ukondla ngokweqile kuholela ekuvinjweni komgudu womoya ngempushana, ukungakhishwa kahle komoya, nokushisa komoya ojikelezayo.

Isixazululo:

Misa umshini ukuze uhlanze impushana enqwabelene epayipini lomoya, wehlise inani lokuphakelayo, futhi uvule ivalvu yepayipi lomoya ngesikhathi esifanayo ukuze ulawule izinga lokushisa lempahla engenayo ngaphakathi kwebanga elamukelekayo.

5. Amanye amaphutha avamile

Izinkinga zesistimu yokuthambisa: Uma kungekho ukuchichima kwamafutha avela ku-labyrinth seal yesihlalo esinesihlalo, kungase kube ngenxa yokuntuleka kukawoyela, ukwehluleka kwamapayipi noma ukulimala kwephampu yamafutha. Kudingeka ukuhlola nokugcwalisa amafutha, ukulungisa ipayipi noma ukufaka esikhundleni sephampu yamafutha.

Ukunyakaza okungajwayelekile kwerola ehambayo: Kungenzeka ukuthi umfutho we-nitrogen accumulator ayanele noma wonakele. Kuyadingeka ukuhlola nokulungisa ingcindezi ye-nitrogen accumulator noma esikhundleni sezingxenye ezilimele.

Izinga lokushisa eliphezulu likawoyela we-hydraulic: Kungenzeka ukuthi isistimu inokuvuza okukhulu kwangaphakathi noma iphampu ibisebenza isikhathi eside kakhulu. Isistimu ye-hydraulic idinga ukuhlolwa futhi ilungiswe.

Inkinga ye-roll gap: Uma igebe le-roller likhulu kakhulu, kungenzeka ukuthi indawo ye-roller igugile kakhulu, ayikho ingcindezi, noma kukhona ukuqoqwa kwezinto ezibonakalayo phakathi kwama-roller; uma igebe le-roller lincane kakhulu, kungenzeka ukuthi kunenkinga ngosayizi we-gap block noma isikhundla senzwa yokufuduka isethwe ngokungalungile. Kudingekile ukulungisa noma ukushintsha izingxenye ngokuvumelana nesimo esithile.

I-roller ibambekile noma ingajiki: Kungenzeka ukuthi kunodaba lwangaphandle phakathi kwamarola, izinto eziningi kakhulu zigcinwa phakathi kwamarola ekuqaleni, ukwehluleka kwemoto noma ukwehluleka kokunciphisa. Kuyadingeka ukuhlanza izinto zangaphandle, ukunciphisa inani lezinto ezigcinwe ekuqaleni, futhi uhlole futhi ulungise injini noma isinciphisi.

Ngamafuphi, amaphutha avamile we-high pressure grinding rolls ahilela izici eziningi, okudingeka zihlolwe futhi zixazululwe ngokuvumelana nesimo esithile. Ekusetshenzisweni kwansuku zonke, ukusebenza kufanele kwenziwe ngokuqinile ngokuhambisana nezinqubo zokusebenza, futhi ukugcinwa kwemishini kufanele kuqiniswe ukuze kuncishiswe ukuvela kwamaphutha.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com