-

Produkte

-

Toepassing

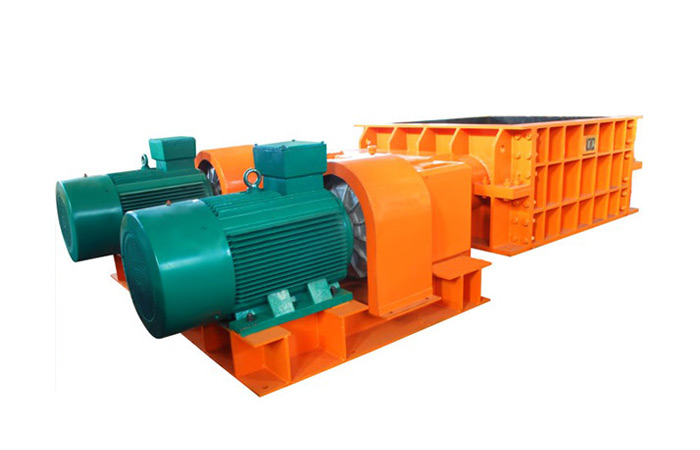

Imishini yokuchoboza ihlukaniswe yaba yi-crusher yomhlathi, i-gyratory crusher, i-cone crusher, i-roller crusher, i-rotary disc crusher, i- impact crusher kanye ne-sando crusher ngokuya ngesakhiwo nomgomo wokusebenza.

I-jaw crusher: Inezici zesilinganiso esikhulu sokuchotshozwa, ikhwalithi yomkhiqizo ofanayo, isakhiwo esilula, ukusebenza okuthembekile, ukugcinwa okulula, izindleko zokusebenza ukonga, njll. Izinto ezihlukahlukene ezingadluli ku-320MPa.

I-cone crusher: isilinganiso esikhulu sokuchotshozwa, ukusebenza kahle okuphezulu, usayizi wezinhlayiyana ezifanayo, ikakhulukazi ezisetshenziselwa ukuchotshozwa okuphakathi nokucolekile kwamadwala aphakathi nendawo.

I-crusher enomthelela: Ingakwazi ukuphatha izinto ezinobude obuseceleni obuyi-100-500mm, futhi amandla ayo okucindezela angafinyelela ku-350MPa. Inezici zesilinganiso esikhulu sokuchotshozwa, izinhlayiya ze-cubic ngemva kokuchotshozwa, nosayizi wezinhlayiyana ezifanayo. Isetshenziswa kakhulu ekugxotsheni amatshe kubunjiniyela bomgwaqo omkhulu. phakathi.

I-Hammer crusher: ilungele ukuchoboza amaminerali ezinto ezahlukahlukene eziphukayo. Amandla acindezelayo wento akumele adlule ku-100MPa, futhi umswakama akufanele udlule u-15%.

Uma ukhetha i-crusher, uhlobo, ubulukhuni, usayizi wezinhlayiyana zezinto ezingenayo neziphumayo, okukhiphayo kanye nendawo yokwakha yezinto ezichotshoziwe kufanele kucatshangelwe ngokugcwele.

Izinhlobo ezahlukene zezinto ezinobunzima obuhlukile. Ngokuvamile, ukuphakama kokuqina, kuya phezulu kwe-coefficient yobunzima bokuchotshozwa. Lapho kuchotshozwa amatshe aqinile noma aqinile, okokusebenza kokuchotshozwa kwemihlathi kufanele kusetshenziswe njengento eyinhloko yokuchotshozwa. Lapho uchoboza amatshe aqinile-aqinile noma athambile, i-cone, counterattack noma ama-crushers isando angasetshenziswa ngokuqondile.

Uma ubukhulu bezinto bukhulu, i-crusher yomhlathi ingasetshenziswa njengokuchotshozwa okuyinhloko; lapho ubukhulu betshe buncane futhi budinga ukwakhiwa kwesigaba esithile samatshe, kuyadingeka ukusebenzisa imishini ehlanganisiwe yokuchoboza nokuhlola, njenge-crusher yomhlathi. Imishini ehlanganisiwe yokuchoboza eyenziwe ngekhoni noma i- impact crusher kanye ne-sando crusher.

Okuqukethwe kwamanzi kwempahla kuzophinde kuthinte ukukhethwa kwe-crusher. Uma okuqukethwe kwamanzi kukukhulu kakhulu, okusanhlamvu okucolile kuzoqoqana noma kunamathele kokusanhlamvu okumahhadla ngenxa yokwanda komswakama, ngaleyo ndlela kwandise i-viscosity yezinto, kunciphise isivinini sokukhipha, futhi kwenze Ukukhiqiza kuwile. Ezimweni ezimbi kakhulu, kungase kubangele ukuvinjelwa kwembobo yokukhipha, okuthinta ukukhiqizwa okuvamile.

Izinga lokuthuthukiswa kwe-cleavage ye-ore lithinta ngokuqondile ukukhiqiza kwe-crusher. Lapho itshe lensimbi lichotshozwa, kulula ukuphuka eduze kwendawo yokuqhekeka. Ngakho-ke, ukukhiqiza kwe-crusher kuphakeme kakhulu kunokwensimbi enesakhiwo esiminyene lapho insimbi ene-cleavage ethuthukisiwe ichotshozwa. .

Usayizi wezinhlayiyana ezingenayo neziphumayo zisetshenziselwa ukwahlulela uhlobo nezinga lokuchoboza lemishini yokuchoboza edingekayo. Uma okuqukethwe kwezinhlayiya ezimahhadla (ezinkulu kunosayizi wembobo yokukhipha) ezintweni ezichotshoziwe ziphakeme noma isilinganiso se-ore enkulu kunazo zonke kuya kububanzi bembobo yokuphakela sikhulu, isilinganiso sokuchotshozwa okudingeka sifinyelelwe yi-crusher. (ubukhulu bezinhlayiyana zento ngaphambi kokuchotshozwa kanye nobukhulu bezinto ngemva kokuchotshozwa) Isilinganiso sosayizi wezinhlayiyana zezinto) sikhulu, ngakho ukukhiqiza kuyancipha.

Uma okuqukethwe kwezinhlayiya ezinhle (eduze noma kuncane kunosayizi wembobo yokukhipha) yezinto ezichotshoziwe kukhulu, noma isilinganiso se-ore enkulu kunazo zonke kuya kububanzi bembobo yokudla sisincane, isilinganiso sokuchotshozwa kufanele sibe okufinyelelwe kuncane, ngakho ukukhiqiza kuyathuthukiswa ngokufanayo. Uma usayizi wezinhlayiyana zokuphakelayo mkhulu futhi usayizi wezinhlayiyana zokukhipha umncane, ukuchotshozwa kwesibili noma ukuchotshozwa kwezigaba eziningi kuvame ukudingeka.

Isidingo sokukhipha siyinkomba ebalulekile yokunquma imishini yokuchoboza. Isidingo sokuphuma siphezulu, ubukhulu bemishini yokuchoboza edingekayo, kanye nokokufaka okuhambisanayo nokuphumayo kuzokwanda.

Isimo esithile sendawo yokwakha siyisici esiqondile kakhulu esithinta ukukhethwa kwemishini ye-crusher, njengobukhulu bendawo yokwakha, indawo ethile yokubeka imishini yokuchoboza, njll.

Kubaluleke kakhulu kubasebenzisi ukuthi bahlole zonke izici zomkhiqizi lapho bethenga i-crusher. Kuphela ngokukhetha umkhiqizi ofanelekayo lapho izinzuzo zezomnotho zomsebenzisi zingaqinisekiswa kakhudlwana. Lapho ukhetha umenzi, amaphuzu alandelayo kufanele anakwe:

Amandla aphelele abonakala kakhulu esikalini sokukhiqiza somkhiqizi, noma ngabe uneqembu lakhe lochwepheshe le-R&D kanye nethimba lokuhlola ikhwalithi, noma ngabe umkhiqizi unemali eqinile, nokuthi unamandla okwethula ukucutshungulwa kwangaphandle okuvuthiwe.

Izinga lemishini lizonquma ngokuqondile ukusebenza kwemishini. Imishini yekhwalithi ephezulu izinzile futhi ithembekile ekusebenzeni kwangempela, inezinga eliphezulu lokusebenza, ukusebenza kahle kokukhiqiza okuphezulu, izinga eliphansi lokuhluleka kanye nempilo ende yesevisi. Ukuya kumkhiqizi ukuyohlola endaweni, ungaba nokuqonda okuphelele ngendawo yokusebenzela yokukhiqiza yomkhiqizi, isikali, ubuchwepheshe bemishini kanye nezinsiza ezisekelayo, futhi ungahlola umshini ukuze ubheke ukusebenza nokusebenza kwemishini. .

(1) Ukuphindela kwekhasimende

Ngemva kokuba impahla yekhasimende isiqalile ukusebenza, umenzi kudingeka alandelele futhi abuyele ekhasimendeni ngezikhathi ezithile ukuze aqonde isimo samanje sokusebenza kwemishini, umthamo wokukhiqiza, ukusetshenziswa kwezingxenye zokugqoka kanye nezinkinga ikhasimende elihlangabezane nazo.

(2) Ukunikezwa kwezinsiza

Khetha umkhiqizi onohlelo oluphelele lokuhlinzeka ngezingxenye zangemuva kokuthengisa ukuze uqinisekise ukuthi izidingo zokushintsha izingxenye zekhasimende ziyahlangatshezwa okokuqala futhi unciphise isikhathi sokungasebenzi sekhasimende sokunakekela.

Kafushane, lapho ukhetha imishini yokuchoboza kanye nabakhiqizi, ukukhethwa kwemishini kufanele kusekelwe ezidingweni zokukhiqiza kanye nezakhiwo zezinto ezibonakalayo. Umkhiqizi ofanelekayo akakwazi kuphela ukuqinisekisa ikhwalithi nokusebenza kwe-crusher, kodwa futhi anikeze usizo olufanele lokusetshenziswa kwemishini. Khumbula ukuthi ungaqhubeki nokushibhile ngobumpumputhe futhi ungayinaki ikhwalithi yemishini.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com