-

Produkte

-

Toepassing

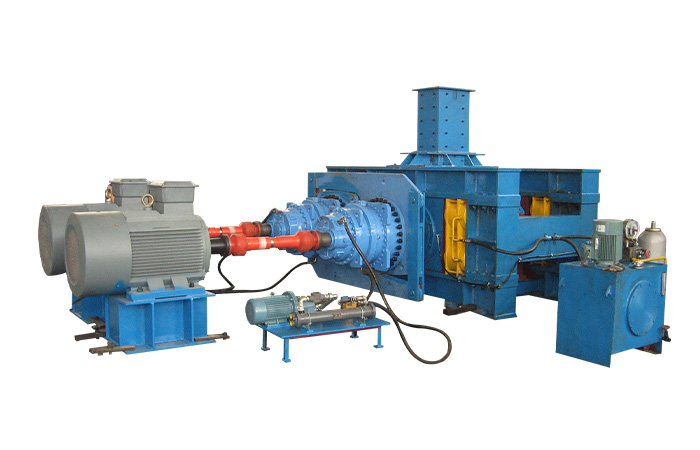

I-high-pressure roller mill isetshenziswa njengesisetshenziswa sokugaya esisebenza kahle kakhulu emabhizinisini ezimayini. Isebenzisa umgomo we-static pressure pulverization. Nokho, ngenxa yokuthi izinto ezisetshenziswayo ziyasebenza, amandla engxenye ngayinye makhulu, okubangela ukundindizela okukhulu. Ukuze kuqinisekiswe isigayo se-roller ye-high-pressure Umshini uzinzile futhi uqinile, futhi ifreyimu nesisekelo kudingeka kufakwe ngokuqinile ngokuhambisana nezincazelo. Ngezansi, umhleli we-Zhongyuan uhlanganise izindlela zokufaka nezinyathelo zokuphepha zohlaka lokugaya olunomfutho ophezulu ukuze kube yinkomba yakho.

(1) Ngaphambi kokufaka isisekelo se-high-pressure roller mill, sebenzisa i-parafini ukuze uhlanze amafutha aphikisana nokugqwala, bese uyibeka epuleti lesisekelo sophondo. Indawo yokuxhumana phakathi kwesisekelo nophondo ekushintsheni okuningana iyadingeka ukuze ifinyelele ku-80 yendawo yonke. %;

(2) Faka i-base kanye ne-shim base plate kuma-anchor bolt, sebenzisa izinga ukuze ulungise izinga lesisekelo, bese uhlanza indawo yokuxhumana yesisekelo kanye nohlaka ngophalafini, bese ufaka ifremu esisekelweni ngemva kokuqeda. ;

(3) Lungisa i-shim futhi usebenzise i-feeler gauge ukuze uhlole igebe phakathi kwesisekelo nohlaka. Ngemuva kokuthi ukulungiswa sekuqediwe, sebenzisa i-torx wrench kanye ne-hydraulic wrench kagesi ukuze uqinise ama-bolts izikhathi ezine, futhi usebenzise i-glue yokuqinisa intambo ngaphambi kokuqinisa. Vimbela ngempumelelo ukuxegiswa kwebhawodi okubangelwa ukudlidliza komshini.

(1) Sebenzisa uphalafini ukuhlanza i-roller slide ye-rack, bese uhlola futhi usule ubuso besilayidi;

(2) Sebenzisa irula eleveli ukuze ubeke kumzila wama-slide, ulungise ushimu ukuze wenze isilayidi sibe izinga ekuqaleni, bese usebenzisa imitha yeleveli yefreyimu nerula ukukala isilayidi, futhi ulungise ushimu ukuze uleveli kahle;

(3) Ngemva kokuqedwa kokulinganisa okuhle, sebenzisa i-welding kagesi ukuze ulungise uhlangothi lwe-shim ukuze luqine futhi luzinze;

(4) Qinisa amabhawodi izikhathi ezine ngesikrufu sika-Torx nesikrufu sikagesi esisebenza ngogesi, bese usebenzisa iglue eqinisa intambo ngaphambi kokuqiniswa, okungavimbela ngempumelelo amabhawodi ukuthi angaxegi okubangelwa ukudlidliza komshini.

1. Indawo yokuxhumana phakathi kwesisekelo ne-shim base plate kufanele ingabi nama-burrs;

2. Igebe phakathi kwendawo yokuthintana yesisekelo kanye ne-shim base plate kufanele ibe ngaphansi kuka-0.02mm, futhi uhlole ngegeji yokuzizwa engu-0.02mm;

3. Uma usebenzisa izinga ukuze ulinganise isisekelo, ukuchezuka kwezinga kufanele kube ngaphansi kuka-2mm;

4. I-roller slide yohlaka kufanele ingabi nama-burrs nokulimala;

5. Ngemuva kokuthi uhlaka selulinganisiwe, iphutha le-longitudinal nelivundlile akumele libe likhulu kuno-0.02mm;

6. Ngemuva kokufakwa kwesisekelo kanye ne-rack, hlola ukuphambuka ngesikhathi bese ubhala umphumela wesheke.

Okungenhla yikho konke okuqukethwe kwendlela yokufaka kanye nezinyathelo zokuphepha zohlaka lomshini wokugaya umfutho ophezulu. Ngethemba ukukusiza. Ukufakwa kwefreyimu kanye nesisekelo akuqinile, okungenye yezizathu eziyinhloko zokudlidliza komshini wokugaya i-high-pressure roller. Ngakolunye uhlangothi, umsindo uthinta umsebenzi wama-opharetha asendaweni, futhi ngakolunye uhlangothi, ungase ubangele uhlelo lokudlulisa umshini wokucindezela ophezulu ukuba luvele ngesikhathi senqubo yokudlidliza. Ukwehluleka nokugqoka kwangaphambi kwesikhathi kwezingxenye, ngakho-ke njengezinye izingxenye, kuyadingeka ukunaka izimo zabo zokufaka.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com