-

Produkte

-

Toepassing

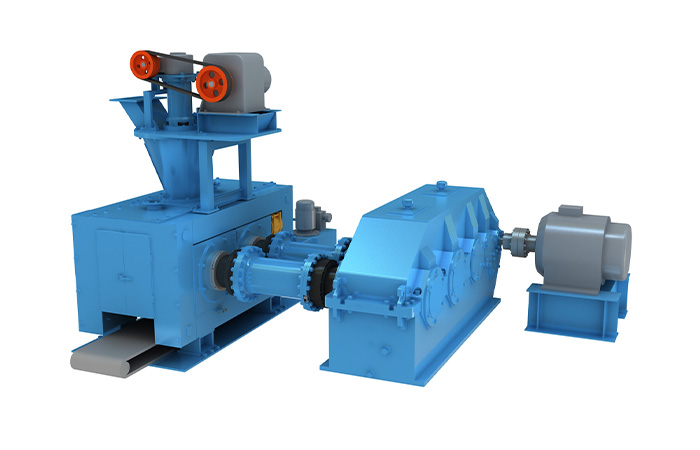

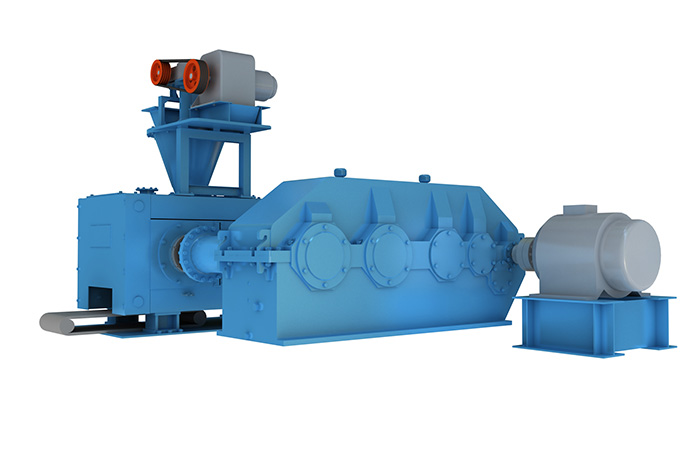

Ekukhiqizweni kwezimboni zanamuhla, ukuze kugcinwe izinto zokusetshenziswa, imishini ehlukahlukene ezimbonini ezahlukahlukene ivela emfudlaneni ongapheli. Njengesisetshenziswa esibalulekile sokucubungula nokusebenzisa kabusha izinto ezisele, umshini we-briquetting nakanjani uzobhekana nokuguga nokuguga okuhlukahlukene ngesikhathi sokusetshenziswa. Izingxenye ezibalulekile zokusebenza emshinini wokubopha izikhumba ze-roller zivame ukuguga futhi zishintshwe.

Isikhumba se-roller siyingxenye ye-cylindrical enezisekelo zebhola ezigujwe ebusweni bomgogodla we-roller wokucindezela ibhola. Ngokuvamile, izinto ezibonakalayo zicindezelwa ama-hydraulic drive rollers, akhiwa amasokhethi ebhola esikhumba se-roller. Njengengxenye yokucindezela okulula kakhulu yokugqoka ibhola, ukushintshwa okuphindaphindiwe akwamukeleki ku-opharetha, kodwa isikhumba se-roller esigugile somshini wokucindezela ibhola asikwazi ukuhlangabezana nesidingo sokukhiqiza, futhi akwanele uma singashintshwa, ngakho-ke kubaluleke kakhulu ukuba gcina isikhumba se-roller ngesikhathi sokusetshenziswa. Iyiphi indlela yokunakekelwa kwesikhumba se-roller?

Kunezindlela ezine zokufaka zesikhumba se-roller sokucindezela ibhola. Ama-ball press ahlukene asebenzisa izindlela ezahlukene, kodwa amazinga okufaka ayefana. Okokuqala, ukufakwa kwesikhumba se-roller akukwazi ukukhishwa. Uma isikhumba se-roller sesivele sihlakazekile ngesikhathi sokufakwa, khona-ke Ingasaphathwa yokukhiqiza, ukuma kwesokhethi yebhola esikhumbeni se-roller kufanele kuhambisane, ngaphandle kwalokho ukucindezela kwebhola ngeke kukhiqize amabhola, amabhola avulekile, futhi ukuma okuyindilinga akulona iqiniso. Imiphetho yezidleke igqoka omunye nomunye, futhi izikhumba ze-roller zidinga ukushintshwa ngemva kwesikhathi eside, okungafaneleki ukulahlekelwa.

Insimbi evamile yesikhumba somshini wokucindezela ibhola i-65 manganese alloy, futhi insimbi evamile yesikhumba somshini wokucindezela ibhola i-92 chromium molybdenum. Inkampani yethu isebenzisa i-forging yezinga eliphezulu - insimbi enensimbi. Izikhumba ze-Casting roller azikwazi ukumelana nokugqoka, kodwa inzuzo yizindleko eziphansi. Abanye o-opharetha ababi emalini, futhi akuyona into enkulu ukushintsha izikhumba zamarola njalo. Kodwa-ke, kuma-opharetha abasebenzisa izikhumba ze-roller ezakhiwe, izikhumba ze-roller ezihlala isikhathi eside, ziba ngcono. Kungcono ukungayifaki esikhundleni, kodwa akudingekile ukugcina isikhumba se-roller sokucindezela ibhola.

Ngemuva kokuthi isikhumba se-roller sifakwe ngendlela efanele, ukuze kuncishiswe ukugqoka kwesikhumba se-roller, izinyathelo ezithile zokuzivikela kufanele zithathwe ngaphambi kokuba imishini isebenze. Ozibuthe kumele bafakwe ku-conveyor yebhande lokuphakela ukuze kuvinjwe insimbi eqinile ukuthi ingangeni esikhumbeni se-roller futhi ibangele ukuthi isikhumba se-roller sibophe. Enqubweni yokuthuthwa kwezinto ezibonakalayo, abasebenzi kufanele bakhethe amatshe ngesikhathi, futhi baqinisekise ukuthi usayizi wezinhlayiyana wezinto ezibonakalayo ungaphansi kuka-3 mm, ukuze kuqinisekiswe impilo yesevisi yesikhumba se-roller futhi baqinisekise ukuthi ngeke kube nezinkinga. ngokwakhiwa kwezinto; Ngaphambilini, abasebenzi baphinde babheka ama-roller okucindezela ibhola ukuze babone ukuthi akukho yini ukuxega noma ukuchezuka. Uma kwakukhona into enjalo, ukuqhubeka nokusebenza kwakuzokwenza kalula ukuthi ama-roller aphule, futhi ukulahlekelwa kwakungeyona nje isikhumba se-roller.

Idivayisi yokuvikela umshini wokudonsa amanzi ingenye yezinhlaka zomshini wokwenza i-briquetting. Ngenkathi kunikeza ingcindezi yokukhiqiza edingekayo yamaroli, kungaphinde kubangelwe ukugcwala kwe-hydraulic cylinder piston rod lapho kufakwa izinto eziningi kakhulu phakathi kwezikhumba ezigoqekayo noma kubhlokhi yensimbi. Ipompo le-hydraulic eliwumphumela liyama kanye noshintsho lwengcindezi lwenza i-accumulator isebenze njengesivimbeli, futhi ngesikhathi esifanayo, ivalvu yokukhulula iyavuleka ukubuyisela uwoyela ukuze wenze i-piston rod isuke, ngaleyo ndlela ikhulise igebe phakathi kwezikhumba ezimbili zamarola. awusekho umonakalo omkhulu.

Ukuze idivayisi yokuvikela i-hydraulic idlale indima yayo efanele, kuyadingeka ukwenza umsebenzi ojwayelekile wokulungisa kuyo. Ngesikhathi somsebenzi, ukunikezwa kwengcindezi yedivayisi ye-hydraulic kufanele kube okunengqondo, futhi ukushaywa akufanele kube ngokweqile. Ngesikhathi esifanayo, kuyadingeka ukuqinisekisa ukuthi izinga lokushisa lamafutha lamafutha we-hydraulic alikwazi ukuba liphezulu kakhulu noma liphansi kakhulu. Ezikhathini ezijwayelekile, uwoyela we-hydraulic kufanele uhlungwe njalo. Uma kukhona ukungcola emafutheni, kulula ukulimaza uphawu. , okubangela ukuthi isenzo sihluleke, ngisho nesilinda esiyinhloko sizoba nemihuzuko.

Indawo yokukhiqiza ehlanzekile ingenza abasebenzi bakwazi ukugcina isimo sengqondo esihle sokusebenza emsebenzini. Ukuhlanzwa kwenhlanzeko kufanele kwenziwe ngemuva komsebenzi nsuku zonke. Ngaphezu kokuhlanza umhlabathi, ukuhlanza imishini nakho kungenye yezindlela zokunakekela isikhumba se-roller sokucindezela ibhola. Kukhona uthuli oluningi. Kulula ukubangela ukunqwabelana kothuli ezingxenyeni ezihambayo zemishini kanye nezingxenye eziveziwe zama-bearings. Uma ingahlanjululwa isikhathi eside, izothinta ukuphepha nokukhiqiza okuvamile, futhi ibangele nokulimala kwemishini; ezinye izinto ezicindezelwa yi-ball press ziyagqwala. Lapho izinto zokusebenza zihlanzwa, izinto ezisele esikhumbeni se-roller kanye ne-socket yebhola kufanele zihlanzwe ukuze kuvinjelwe isikhumba se-roller ukuthi singagqwali isikhathi eside, ngaleyo ndlela kubangele umonakalo esikhumbeni se-roller.

Ekukhiqizweni kwansuku zonke kwebhizinisi, indlela yokugcinwa kwesikhumba se-roller yomshini we-briquetting kufanele ilungile, ukuze kuqinisekiswe ukuthi le ngxenye yokugqoka yomshini we-briquetting ayikho engozini kakhulu, futhi izinzuzo zebhizinisi zizokwenyuka ifomu elifihliwe. Kungenye yezindlela zokulungisa izinto ezidingwa opharetha ukuze bakwazi ukuzisebenzisa kahle.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com