-

Produkte

-

Toepassing

Ekukhiqizeni nasekusetshenzisweni kwezinto eziningi ze-powdery noma ze-granular, ukuze uzithuthe futhi uzisebenzise ngokuphumelelayo, kuyadingeka ukusebenzisa imishini ye-briquetting ukuze ucindezele lezi zinto zibe ngama-pellets, kodwa ezinye izinto zikhethekile ngenxa yezici zabo ezikhethekile. Izici zomzimba kanye nenqubo yokukhiqiza yomkhiqizo ayikwazi ukucindezelwa ibe yisimo ngesikhathi esisodwa, ngakho-ke kuyadingeka ukukhetha inqubo yesibili ye-briquetting yomshini we-briquetting ukucindezela impahla.

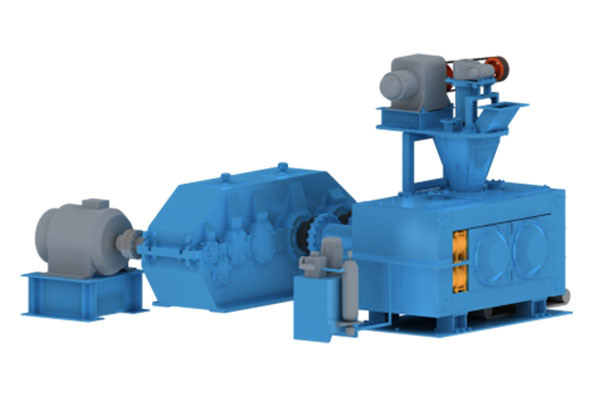

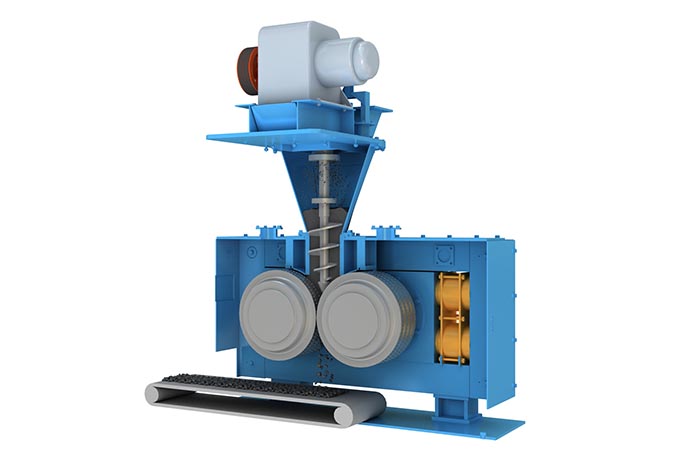

Ngaphansi kwezimo ezijwayelekile, lapho impahla ingeke yanezelwa nanoma iyiphi i-binder futhi idinga ingcindezi enkulu yokwenza ibhola, imishini yokugcwalisa ingcindezi ephezulu kanye ne-ultra-high (efana nomshini wokugcwalisa i-high-pressure okhiqizwe i-Zhongyuan Mining Machinery) isetshenziswa. ngokucindezelwa kwezinto ezibonakalayo, noma Shintsha inqubo ye-briquetting yezinto ezibonakalayo, okungukuthi, ukusebenzisana nezinye izisetshenziswa ze-briquetting yesibili, ngakho-ke ngaphezu komshini we-briquetting, okokusebenza okudingekayo ku-briquetting yesibili imi kanje:

1. Ibhande elihambisa ibhande: okokusebenza okuthutha okuthutha impushana kuyiyise kusikheshi sebhakede. Ngokusebenzisa ukwakheka kwesayithi okunengqondo, ingakwazi ngesikhathi esisodwa ukuthwala impahla ngemuva kokufakwa kwe-briquetting kokuqala komshini we-briquetting futhi iyithumele ku-lifti yebhakede ngesikhathi esifanayo umshini.

2. Ikheshi lebhakede: dlulisa izinto ezidluliswa yibhande elihambisa ibhande kumhambisi wesistimu yokugaya nokuchoboza.

3. Umshini wokuhlola izinto ezibonakalayo: Izinto ezihlukile ze-granular zihlukaniswa ngesikrini futhi zithunyelwa kumshini wokugaya nokuchoboza noma emgqonyeni wokuhlinzeka.

4. I-chute yokusabalalisa: amabhola afanelekayo nangafaneleki ahlukaniswa ngokudlidliza ngokusebenzisa ukucindezela kwesibili.

5. Imishini yokugaya nokuchoboza: Ingakwazi ukuchoboza futhi igaye izinhlayiya ezinkulu nezinto ezingakwazi ukwakheka ngesikhathi esisodwa.

6. I-screw conveyor: phakela izinto ezisetshenziswayo kusuka emgqonyeni wokuhlinzeka kuya emshinini wokufaka ama-briquetting ngemva kokulinganisa nokukala.

1. Okokuqala, impahla engaphansi emgqonyeni wokuhlinzeka ithunyelwa emshinini wokufaka i-briquetting ngokusebenzisa isidluliseli sesikulufu se-briquetting yokuqala, futhi impahla ngemva kokucindezela kokuqala ithunyelwa emshinini wokuhluza ngekheshi ukuze kuhlolwe ukudlidliza;

2. Impahla ehloliwe ithunyelwa kumshini wokugaya nokuchotshozwa ukuze kucutshungulwe bese kukhishelwa emgqonyeni omaphakathi njengenhlanganisela ye-briquetting yesibili;

3. Izinto ezihloliwe zingena kusisele sempushana ecolekile, bese kuthi impushana ecolekile kanye nesamba esisesiseleni esimaphakathi kuthunyelwa emshinini wokubopha nge-screw conveyor ukuze kwenziwe i-briquetting yesibili ngokwesilinganiso esithile;

4. Ngemva kokuhlanganiswa kwesibili, ama-pellets azongena e-chute yokusabalalisa ngekheshi. Ngaphansi kwezimo ezijwayelekile, ama-pellets azovezwa futhi ahlolwe yi-chute yokusabalalisa. Ama-pellets aqediwe azoya ngqo esigabeni esilandelayo sokucubungula, futhi ama-pellets angaqediwe azothunyelwa ukuchoboza futhi Umshini uchotshoziwe bese ugaywa, bese ubuyiselwa emgqonyeni wokuhlinzeka womshini wokugaya, njengesilinganiso se-aggregate kanye impushana emihle ye-briquetting yesibili.

1. Ukuze kuqinisekiswe ukutholakala kwempahla eyanele emshinini wokufaka amabrikhi, esimweni lapho inani elikhulu lezinto eziphakelwayo yisiphakeli, indawo yokukhipha impahla echichimayo kufanele isethwe kudivayisi yokuphakela isikulufu, futhi okuchichimayo kufanele kubuyiselwe kuyo. umgqomo wokuphakela umshini we-briquetting ngokusebenzisa i-lift.

2. I-chute yokusabalalisa kufanele futhi ifakwe ukuchichima. Uma i-chute yokusabalalisa isigcwele, ibhola lizogeleza liphuma ekuchichimeni liye emshinini wokuhlola odlidlizayo, futhi okokusebenza okusefiwe kuzongena emgqonyeni wokujikeleza webhola eliluhlaza ukuze ligcinwe. Uma uhlelo lwehluleka, amabhola asebhokisini lokujikeleza kwebhola eliluhlaza aphakanyiswa ikheshi aye endaweni yokusatshalaliswa bese azungeza futhi.

3. Ngaphambi kokuqhubeka nokucubungula okusemthethweni, qaphela ukulungisa ukucindezela kokwenza ibhola komshini ngamunye we-briquetting kanye ne-symmetry ye-press roller ukugwema i-briquetting yesibili kanye nokunamathela kwesikhunta okubangelwa izinkinga zemishini.

4. Naka umzila wokuphakela wempahla ngayinye edlulisayo kanye nemishini yokuhlola, futhi ugweme isitoreji esixubile sezinto eziyisisekelo zokucubungula nokucubungula kabusha ekwakhiweni kwesayithi nenqubo, ukuze uqinisekise ukuthi isilinganiso sempahla ye-briquetting yesibili sinembe kakhudlwana.

Okuqukethwe ngenhla yisingeniso esinemininingwane yenqubo yokubopha i-briquetting. Ngokuyinhloko, ezintweni ezingenakukwazi ukwakhiwa ngesikhathi esisodwa, isilinganiso se-powder esihle kanye ne-aggregate sisetshenziselwa i-briquetting yesibili, engakhuphula kakhulu izinga le-spheroidization kanye nevolumu yamapellets. Ukuminyana ukuqinisekisa ikhwalithi yebhola.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com