-

Produkte

-

Toepassing

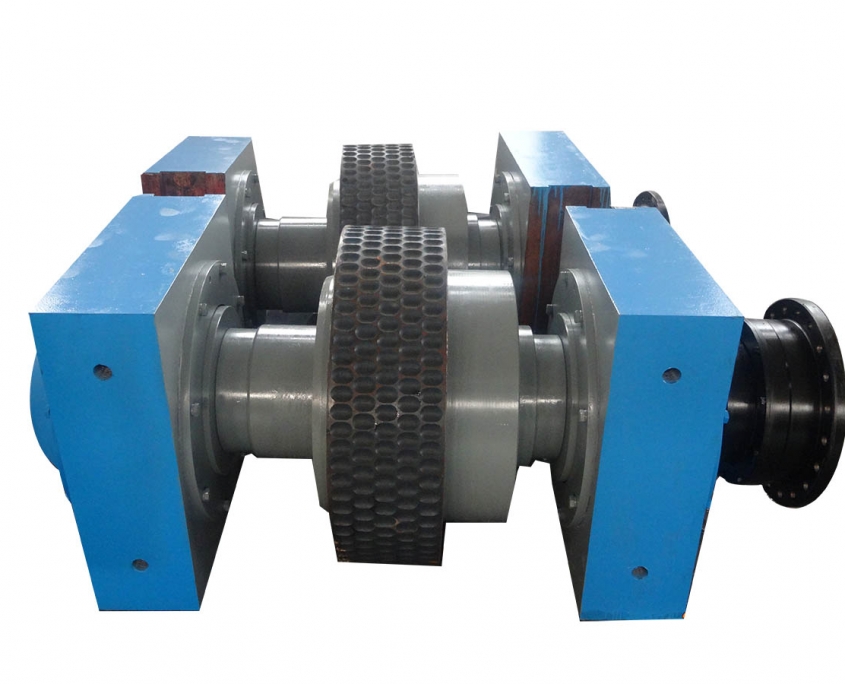

Isikhumba se-roller sokucindezela ibhola siyingxenye eyinhloko yokucindezela ibhola. Izinga lesikhumba sebhola lokucindezela ibhola linquma impilo yesevisi yokucindezela ibhola ngokuqondile. Ukuqina kwesikhumba se-roller sokucindezela ibhola kuyipharamitha ebaluleke kakhulu yokukala ikhwalithi yesikhumba se-roller yomshini webhola. Ukuqina kwesikhumba se-roller kuncike kwinombolo yensimbi ye-alloy ekhethiwe kanye nezinga lokugcina lokwelashwa kokushisa.

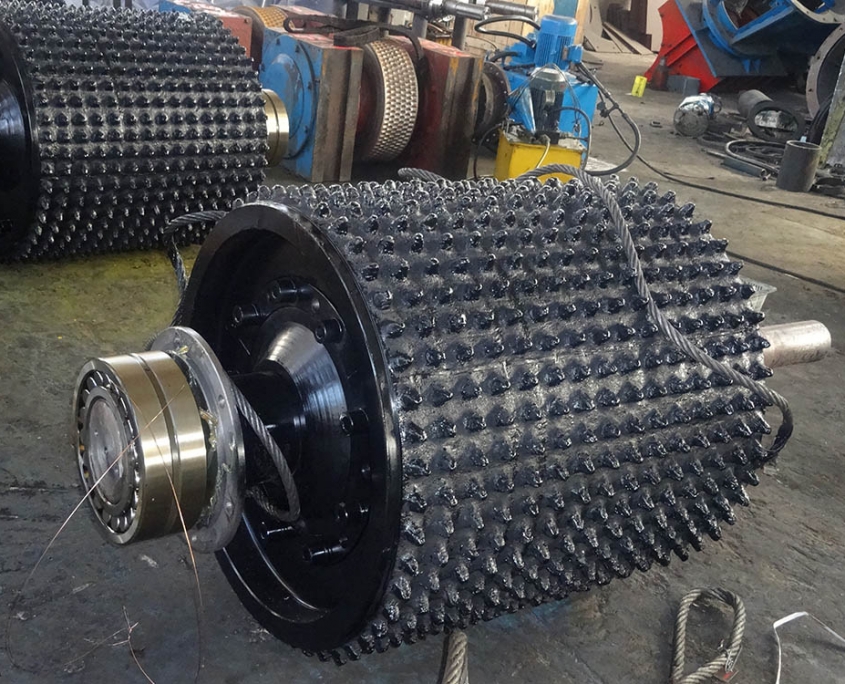

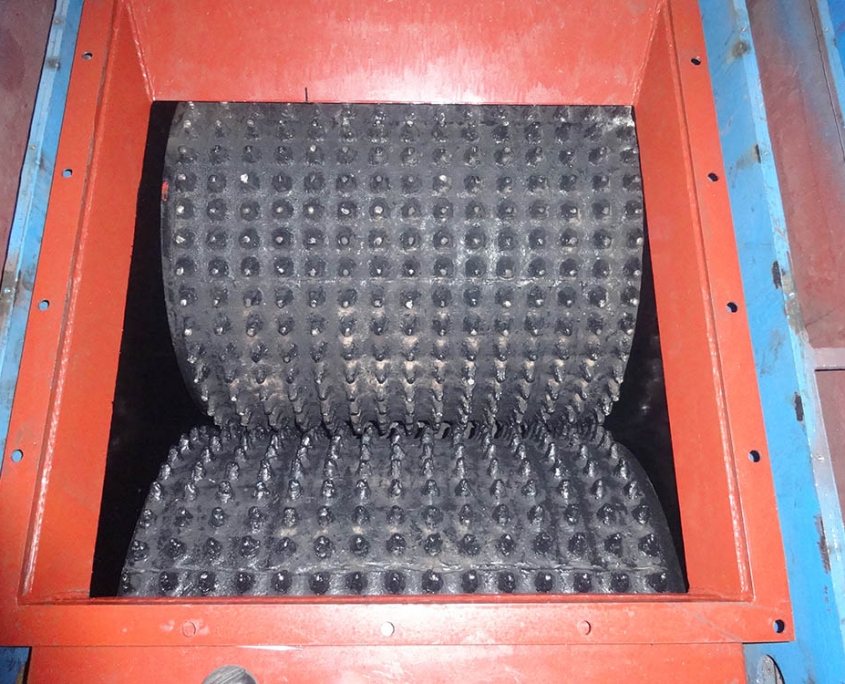

Isikhumba se-roller somshini wokucindezela ibhola senziwa zibe izikhala ngokusho kwemidwebo yesikhumba se-roller, bese siguqulwa ukuze sicacise kuzo zonke izinhlangothi. Isinyathelo esilandelayo ukudweba ibhola kanye nesokhethi kumjikelezo wesikhumba se-roller. Yiqiniso, usayizi nokuma kwebhola kanye nesokhethi kudingeka kunqunywe ngokuhlanganyela ngokuvumelana nobubanzi besikhumba se-roller kanye nezinto ezicindezelwe. Inqubo yokugcina iwukwelapha ukushisa, nakho okubaluleke kakhulu. Endabeni yezinto ezibonakalayo ezifanayo zomqulu, ukuqina komqulu kunqunywa ukwelashwa kokushisa.

Ngokombono wezobuchwepheshe, isikhumba se-roller singahlukaniswa sibe yizinhlobo ezimbili, ukubunjwa nokubunjwa. Ibanga lensimbi elivame ukusetshenziselwa ukuphonsa isikhumba somqulu yingxubevange ye-manganese engu-65, enenani eliphansi uma kuqhathaniswa, kodwa ukuqina kwesikhumba somqulu abukho kakhulu, futhi alikwazi ukumelana kakhulu nokuguga. Ilungele ukucindezela izinto ezithambile njengempushana yamalahle nobumba. Inombolo yensimbi esetshenziswa kakhulu yesikhumba esiwumgunyathi yi-92 Ming molybdenum, enenani eliphakeme nezindleko, kodwa ukuqina kwesikhumba somqulu kuphezulu uma kuqhathaniswa, okungafinyelela ngaphezu kwe-HRC62, elungele ukucindezela izinto ezimahhadla ezifana ne-iron powder. kanye ne-metal ore powder.

Ukuma kwempahla ye-roller yomshini wokucindezela ibhola ukubaluleka kokuthengwa komshini we-powder, futhi isikhumba se-roller sizokhiqiza izingxenye ezithintekayo ekukhiqizeni. Isibonelo, uma impushana yenziwe ngezinto ezinobulukhuni obuphezulu, kufanele ihlolwe. Uma isikhumba se-roller sigqokwa ngemuva kokucindezela, kufanele sishintshwe.

Ukubaluleka kwezingxenye zesikhumba ze-roller ze-ball press kwaziwa kahle, futhi kubaluleke nakakhulu. Uma izinkinga zenzeka ekukhiqizeni isikhumba se-roller sokucindezela ibhola, imiphumela ingacatshangwa. Uma isikhumba se-roller somshini wokucindezela ibhola sithatha isikhathi eside noma sonakalisiwe, ikhasimende kufanele liyishintshe ngesikhathi esifanele ukuze ligweme ukuthi imikhiqizo ekhiqizwayo ayikwazi ukuhlangabezana nezimo ezinqunywe kusengaphambili futhi ibangele ukuchithwa kwezinto zokusetshenziswa.

Ngakho-ke yiziphi izici okufanele ikhasimende lihlulele ukuthi isikhumba se-roller sishintshiwe?

(1) Sebenzisa amathuluzi athile okuhlola ukuze uhlole njalo, futhi izindlela ezithile zokusebenzisa zizoba nemiyalelo ehambisanayo.

(2) Umbono ophelele osuselwe kokuhlangenwe nakho komuntu siqu.

(3) Kuqondile kakhulu ukubheka umphumela webhola.

Ukushintshwa kwesikhumba se-roller somshini wokucindezela ibhola ngokuyinhloko ukuhlakazeka nokufakwa, kodwa enqubweni yokufaka esikhundleni, inqubo ehambisanayo yokususwa kanye nokufaka kufanele ibe yingcweti ukuze kuzuzwe ukushintshwa okuphephile nokuphumelelayo kwesikhumba se-roller.

1. Amandla kufanele avaliwe, futhi inkinobho enkulu ingavulwa.

2. Ngemva kokuba amandla enqanyuliwe, faka uphawu oluyisixwayiso "ngaphansi kokulungiswa" endaweni ecacile.

3. Okokuqala, yenza ukwelashwa kokunciphisa ingcindezi empompini yokugcoba, donsa iswishi yebhande lokuhlinzeka lebhande lemayini, uhlanze i-pumice ekhanda lebhande, futhi ususe izingxenye ezine ezinkulu, njengonogada bembobo yokuphakelayo, ibhodwe elikhulu, ipuleti lekhava, kanye nesembozo sothuli lwekhoni engashintshi. . Ngesikhathi senqubo yokuphakamisa, i-crane idinga ukuqondiswa umuntu okhethekile, futhi igcine ngokuqinile imithetho yokusebenza yokuphakamisa.

4. Uma ibhodi le-lining elidala lingakwazi ukususwa, ungasebenzisa i-welding yegesi ukusika nokuhlanza indawo yangaphakathi ye-rack.

Kunezindlela ezine zokufaka, futhi wonke umuntu angaqhathanisa izingqimba zabo zebhola ukuze afake indlela efanele.

1. Indlela yokuqinisa i-bolt, okungukuthi, umkhono we-roller kanye nehabhu kuklanywe ngezimbobo ze-bolt futhi ziqiniswe ngama-bolts acwengekile aphezulu. Le ndlela ilungele ukuhlakazwa kwendawo yomkhono we-roller. Indlela emanzi, ukucindezela kwebhola okuphansi, ibhola le-kaolin Izinhlelo zokusebenza zomshini.

2. Indlela yokuhlanganisa i-cone sleeve, okungukuthi, umkhono we-roll noma ihabhu yakhelwe nge-taper, futhi iqiniswa umkhono wekhoni ophakathi. Leli fomu livumela ukuhlakazeka komkhono we-roller futhi lisetshenziswa ekucindezeleni okuphansi nokuphakathi kwebhola.

3. Indlela eqinile yokulayisha okushisayo, okungukuthi, umkhono we-roller onesokhethi yebhola uyafudunyezwa futhi ufakwe kuhabhu lamasondo. Leli fomu lomhlangano linokunemba okuphezulu kokucubungula kanye nokulawula okuqinile kokucubungula izinga lokushisa. Imishini ekhethekile kufanele isetshenziswe lapho kushintsha, futhi ngokuvamile isetshenziswa ekucindezeleni amabhola aphezulu. Ukucindezela kwebhola okunamandla.

4. Indlela yokuhlanganisa ukhiye: Ishaft nomkhono kunemifantu eyisihluthulelo. I-shaft kanye nomkhono kuxhunywe ngokhiye. Ngenxa yokuthi i-shaft inemifantu nemicu ebalulekile, ububanzi be-shaft eyinhloko yemishini yokucindezela ibhola bukhulu kancane kunobubanzi be-shaft bomhlangano ongenakhiye. .

Ngemuva kokuthi yonke imisebenzi isiqediwe, umshini unganqanyulwa ukuze usebenze ngesilingo. Ngemuva kokuthi umshini ongenalutho ugijima isikhathi esithile, izinto ezisetshenziswayo zingangezwa ngokujwayelekile ukuqala ukusebenza. Khumbuza wonke umuntu ukuthi isikhumba se-roll sonakaliswe isikhathi eside noma kufanele sishintshwe ngesikhathi esifanele ukuze kugwenywe ukukhiqizwa kwemikhiqizo engahlangabezani nezimo ezinqunyiwe, ukuze kubangele ukuchithwa kwezinto zokusetshenziswa.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com