-

Produkte

-

Toepassing

Emabhizinisini amakhulu ezimayini, umshini we-briquetting uyinto ebalulekile yokwakha impahla, futhi ukusebenza kahle kwawo kuthinta ngqo ukusebenza kahle kokukhiqiza kwebhizinisi. Ukuze kwandiswe ukukhiqizwa, amabhizinisi amaningi avame ukukhulisa ijubane lomshini wokubopha. Ingabe isivinini sokuzungezisa siyayithinta ngempela ikhwalithi yebhola? Ingabe ama-rev asheshayo ayawunyusa ngempela umkhiqizo? Ekuphenduleni le nkinga, umkhiqizi womshini we-briquetting usinike isingeniso esinemininingwane.

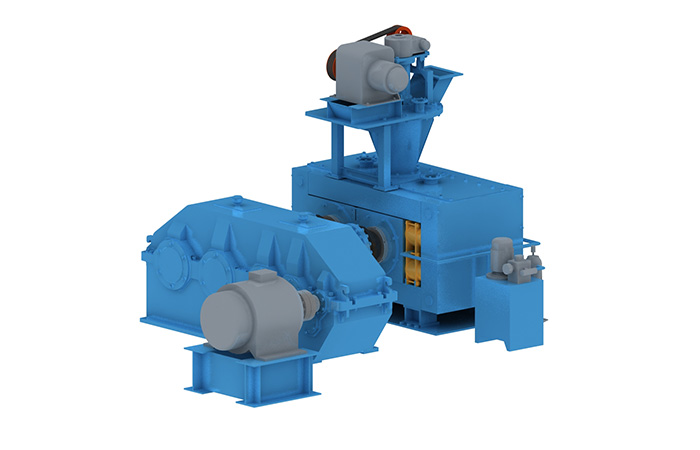

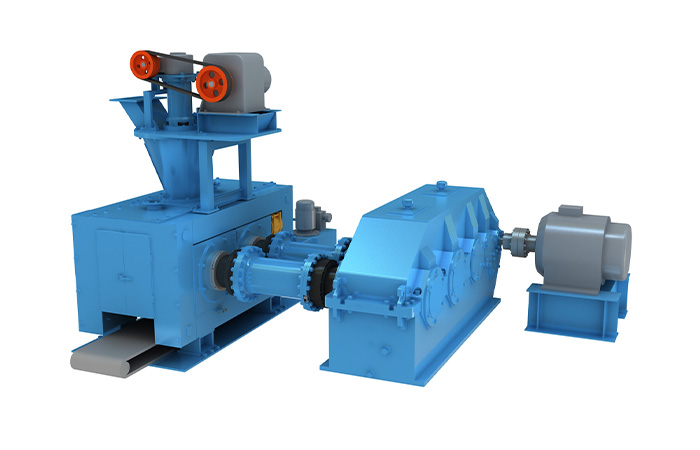

Isimiso sokwakhiwa komshini wokubopha iwukuba ukhiphe izinto eziyimpuphu eziwa esokhethini ngokusebenzisa ama-roller amabili anomumo ofanayo, inombolo efanayo kanye nesimo esifanayo ebusweni ukuze kukhishwe umoya phakathi kwezinhlayiya zezinto ezibonakalayo futhi wenze izinhlayiya zihlangane kakhulu. . kuhlangene ukwenza ama-pellets anesimo esifanayo nosayizi njengesokhethi yebhola. Izinga le-pelletizing yale ndlela yokubumba ithinteka ngokuqondile yizici zezinto ezibonakalayo, kanye negebe phakathi kwama-roller nokucindezela kanye nesivinini sokujikeleza. Lapho yonke imingcele ifanelekile, ikhwalithi yama-pellets izoqinisekiswa.

Ngokuqondene nekhwalithi yamabhola kuphela lapho imingcele yomshini we-briquetting ifanelekile, ingabe ivolumu yokukhiqiza ingathuthukiswa ngokukhulisa isivinini sokujikeleza lapho amanye amapharamitha engalungile? Impendulo ayikho ngempela, futhi kungakhathaliseki ukuthi ijubane lishesha kakhulu noma lihamba kancane, linomthelela omkhulu ekubunjweni kwebhola.

Kubonakala kuyinqubo esheshayo yokukhipha igesi phakathi kwezinhlayiya ngaphansi kwengcindezi, kodwa le nqubo ibuye ithathe isikhathi. Uma kunomoya omningi phakathi kwezinhlayiya zento kanye nomfutho wokubumba ungaguquki, isikhathi esisithathayo ukuze sakheke sizohamba kancane ngokulinganayo. Ngalesi sikhathi, uma ijubane lomshini we-briquetting likhuphuka, isikhathi sokubumba sizoncishiswa, khona-ke kuyoba nenani elikhulu lomoya elingazange likhishwe ngaphakathi kwe-pellet, futhi ukuhlangana kwe-pellet kuyoba. anele, futhi kuzoba namabhola abonakalayo namabhola axegayo.

Ijubane lomshini we-briquetting lihamba kancane, nakuba izinhlayiya zezinto ezibonakalayo zingabuthana esitokisini sebhola isikhathi eside futhi ingcindezi iphakeme. Ngaphansi kwezimo ezivamile ezifana nomswakama wezinto ezibonakalayo, i-binder kanye nengcindezi yomshini we-briquetting, ingagwema ngokuphumelelayo amanga Ukubukeka kwebhola ngokusobala kuzoholela ekwehleni kokusebenza kahle kokukhiqiza, ukwanda kokusetshenziswa kwamandla kanye nesikhathi sokukhishwa okufanayo, nokunciphisa ukusebenza kahle kwezinkampani, okuyikhona futhi izinkampani eziningi ezingafuni ukukubona.

Njengoba isivinini somshini we-briquetting sishesha kakhulu noma sihamba kancane, sizothinta ikhwalithi yamabhola, ingabe lokho kusho ukuthi ukukhishwa komshini we-briquetting kulungisiwe? Impendulo ngokusobala ayiqinisekile. Umthelela wejubane lomshini we-briquetting ungaphansi kwesimo sokuthi imingcele yeminye imishini ye-briquetting ihlala ingashintshiwe, futhi akunakwenzeka ukwandisa ukukhishwa ngokukhulisa isivinini.

Uma ufuna ukukhulisa okukhiphayo ngokwandisa isivinini, into yokuqala okufanele uyenze ukuqinisekisa ukuguquguquka kwezinto ku-prototyping esheshayo, njengokuthi okuqukethwe kwe-binder kunganyuswa yini, nokuthi okuqukethwe umswakama kuyahlangabezana yini nezimo ze-prototyping ngokushesha. Isivinini, ngisho noma i-binder eyengeziwe yengezwa, ikhwalithi yama-pellets ayikwazi ukuqinisekiswa, futhi ingase ithinte ngisho nokusetshenziswa okulandelayo kwamapellets.

Ukwandisa isivinini somshini we-briquetting kuzonciphisa isikhathi sokuba izinhlayiya ezibonakalayo zihlangane zibe ama-agglomerates, futhi azikwazi ukususa ngokuphumelelayo umoya phakathi kwezinhlayiya. Kodwa-ke, ngenkathi ukwandisa ijubane, ukucindezela komshini we-briquetting kungandiswa ngokufanayo, okungase kusheshise isikhathi sokukhishwa komoya nokuqinisekisa ama-pellets. ukuminyana. Kodwa-ke, ukucindezelwa komshini we-briquetting akufanele kube phezulu kakhulu, ngaphandle kwalokho kuzobangela ukugqoka ngaphambi kwesikhathi kwesikhumba se-roller, futhi kuzokwandisa nokushisa komshini wokubhoboza. Ukushisa ngokweqile akulungile ezintweni zokusebenza noma izinto.

Njengoba ukubunjwa komshini we-briquetting kuyi-extrusion yempahla ngama-rollers, lapho isivinini sokujikeleza sanda futhi isivinini sokudla sihlala singashintshiwe, kuzodala izinto ezinganele, izinhlayiya ezibonakalayo kanye nama-hemispheres ekubunjweni ngakunye. Ukwandisa okukhiphayo ngokusebenzisa ingcindezi, kuyadingeka ukuqinisekisa ukudla okwanele ngesikhathi esifanayo ukuze kuqinisekiswe ukuthi ikhwalithi yezinto ezibonakalayo ku-pair ngayinye yamasokhethi ebhola ihlangabezana nezidingo zokwenza i-pellet.

Ngokuphathelene nomthelela wekhwalithi yejubane lomshini we-briquetting, ikakhulukazi kuncike ekutheni izinto zokwakha kanye nemingcele ehlukahlukene yomshini we-briquetting ingafaniswa. , zama ukungashintshi isivinini somshini we-briquetting ngasese, uma ufuna ngempela ukwandisa noma ukunciphisa isivinini, kunconywa ukwenza kabusha ukukhiqizwa nokulungisa iphutha ukuze uqinisekise ikhwalithi yamabhola.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com