-

Produkte

-

Toepassing

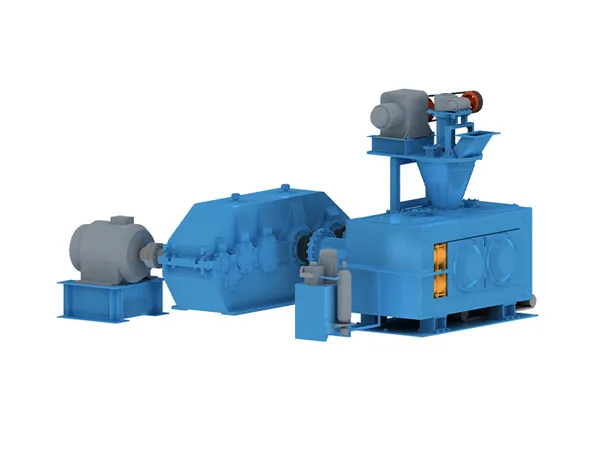

Umshini wokucindezela ibhola, owaziwa nangokuthi i-briquette press noma i-pellet press, wuhlobo lwemishini yomshini ecindezela izinto eziyimpuphu noma eziyimbudumbudu zibe yindilinga noma i-cylindrical shapes. Le mishini ivame ukusetshenziselwa ukwakha ama-briquette noma ama-pellets okusetshenziswa okuhlukahlukene, okuhlanganisa ukukhiqizwa kukaphethiloli, i-metallurgy, ukucubungula amakhemikhali, nokunye. Kunezinhlobo ezahlukene zemishini yokucindezela ibhola, ngayinye yakhelwe izinto ezithile nezinjongo.

Lolu hlobo lomshini wokucindezela ibhola lusebenzisa amarola amabili aphikisayo ukuze ahlanganise into ibe yisimo oyifunayo. Izinto zondliwa phakathi kwama-rollers, futhi ingcindezi esetshenziswa ama-roller yenza izinto zibe amabhola noma ezinye izimo.

Imishini yokucindezela ibhola ye-Hydraulic isebenzisa amasilinda amanzi ukuze ifake ingcindezi ezintweni, ihlanganiswe ibe yifomu oyifunayo. Le mishini iyakwazi ukusebenzisa ingcindezi ephezulu, iyenze ifanelekele ukucubungula izinto ezidinga ukucindezela okukhulu.

Imishini yokucindezela amabhola emishini isebenzisa amasistimu emishini, njengamagiya namakhamera, ukukhiqiza amandla adingekayo ukuze ucindezele into ibe yisimo. Le mishini ingase ibe nomklamo olula uma iqhathaniswa nezinhlelo ezisebenza ngamanzi.

Imishini yokucindezela isikulufu isebenzisa indlela yesikulufu ukuhlanganisa izinto. Izinto ezisetshenziswayo zifakwa egumbini, futhi njengoba isikulufu sizungeza, siphushela impahla phambili, sisebenzisa ingcindezi futhi siyenze ibe yisimo oyifunayo.

Imishini yokucindezela i-piston isebenzisa i-piston ukufaka ingcindezi ezintweni. I-piston ivamise ukushayelwa i-hydraulic noma i-mechanical system, iphoqelela impahla ibe isikhunta esithile noma ife ukuze kwakheke umumo oyifunayo.

Nakuba kungeyona eyemikhiqizo emise okwebhola kuphela, imishini yokucindezela ithebhulethi ingashintshwa ukuze ikhiqize amaphilisi amancane ayisilinda noma amise okwebhola. Le mishini ivame ukusetshenziswa ezimbonini zemithi kanye namakhemikhali ekukhiqizeni amaphilisi nama-pellet.

Ukucindezela Indlela

Imishini yokucindezela amabhola ivamise ukusebenzisa uhlelo lwamarola, amasilinda amanzi, noma imishini yokucindezela ukuze ifake ingcindezi ezintweni futhi iyihlanganise.

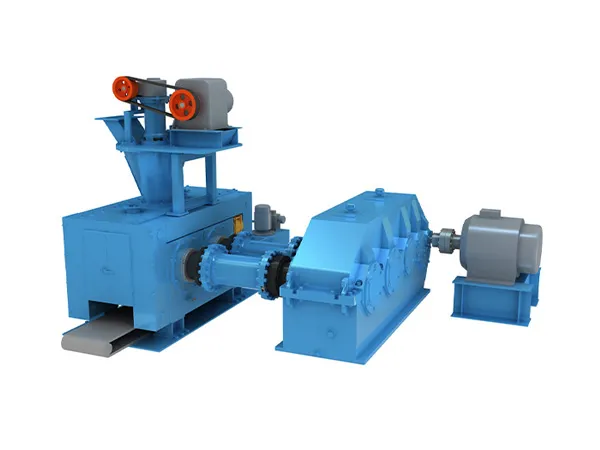

Die noma Isikhunta

I-die noma isikhunta siyingxenye ebalulekile ekhanda into ecindezelwe ibe yifomu elifiswayo, noma ngabe ama-cylindrical briquettes noma ezinye izimo.

I-Hopper kanye nohlelo lokudla

I-hopper yilapho impahla eluhlaza ilayishwa khona emshinini. Eminye imishini inohlelo lokuphakela olwakhelwe ngaphakathi noma ama-conveyor ukuze enze inqubo yokuphakela izinto ngokuzenzakalelayo.

Ukulawula Ingcindezi

Imishini yesimanje yokucindezela ibhola ingase ibe nezinhlelo zokulawula ingcindezi ukuze ilungise izinga lokucindezelwa ngokusekelwe ohlotsheni lwezinto ezicutshungulwayo.

Isistimu Yokupholisa (ongakukhetha)

Kwezinye izinhlelo zokusebenza, isistimu yokupholisa iyahlanganiswa ukuze ipholise amabrikhethi asanda kucindezelwa noma ama-pellets, iwavimbele ukuthi anganamathelani.

Ukulungiselela Material

Izinto ezizocutshungulwa ngokuvamile zisesimweni sempushana, uthuli, izinhlawulo, noma izinhlayiya ezincane. Lezi zinto zingaba izinhlobo ezahlukene ze-biomass, amalahle, amalahle, impushana yensimbi, i-mineral powder, noma ezinye izinto ezifanayo.

Ukondla Okubalulekile

Impahla eluhlaza ifakwa ku-hopper yomshini wokucindezela ibhola. Lokhu kungenziwa ngesandla noma kusetshenziswa isistimu yokuthutha, kuye ngomklamo namandla omshini.

Ukucindezela Nokucindezela

Ngaphakathi emshinini, kunegumbi lokucindezela lapho impahla eluhlaza ingaphansi kokucindezela okukhulu. Umshini wokucindezela, ovame ukuhlanganisa ama-roller noma amasilinda amanzi, ucindezela into ibe yifomu eliminyene nelihlangene.

Ukwakhiwa kwama-Briquettes noma ama-Pellets

Impahla ecindezelweyo ithatha ukuma kwama-briquette noma ama-pellets, kuye ngomklamo othize womshini wokucindezela ibhola. Impahla ehlanganisiwe iphoqelelwa ngedayizi noma isikhunta esiyilolonga ibe yifomu oyifunayo.

Ukukhishwa

Ama-briquette akhiwe noma ama-pellets abese ekhishwa emshinini. Lokhu kungenziwa ngesandla noma ngokuzenzakalelayo, kuye ngezici zomshini.

Amandla: Umthamo womshini wokucindezela ibhola, ovame ukukalwa ngokuphumayo ngehora, unomthelela omkhulu ezindlekweni zawo. Imishini enamandla aphakeme ngokuvamile iza namathegi amanani aphezulu.

Izinga le-Automation: Izinga lokuzenzakalelayo lingasukela ekusebenzeni okwenziwa ngesandla kuye kumasistimu azenzakalelayo noma azenzakalelayo ngokuphelele. Imishini ezenzakalelayo eyengeziwe ivame ukubiza kakhulu ngenxa yezici ezithuthukile nobuchwepheshe obuhlanganisiwe.

Ukuhambisana Kwezinto Ezibalulekile: Uhlobo lwezinto ezibonakalayo umshini wokucindezela ibhola ungacubungula kungaba nomthelela ezindlekweni zawo. Eminye imishini yakhelwe izinto ezithile, kuyilapho eminye iguquguquka futhi ikwazi ukuphatha izinto ezihlukahlukene.

Ibhrendi nomkhiqizi: Abakhiqizi abahlukene banikela ngemishini yokucindezela ibhola enekhwalithi ehlukahlukene kanye nezici. Imikhiqizo esungulwe kahle futhi enedumela elihle ingase ibe namanani aphezulu, kodwa ngokuvamile iza nokwethembeka nokusebenza okungcono.

Izimo Zemakethe: Izimo zemakethe yendawo kanye nokufunwa kwemishini enjalo kungaba nomthelela ezintengo zayo. Izintengo zingahluka ngokusekelwe ekutholakaleni kwemishini efanayo emakethe kanye nokuncintisana phakathi kwabakhiqizi.

Izici ezengeziwe: Eminye imishini yokucindezela ibhola iza nezici ezengeziwe ezifana nezinhlelo zokulawula ezithuthukile, izici zokuphepha, noma izinketho zokwenza ngokwezifiso. Lezi zici zinganikela ezindlekweni zizonke eziphezulu.

Ukusebenza Kahle Amandla: Imishini eyonga amandla ingase ibe nezindleko eziphezulu zangaphambili, kodwa ingaholela ekongeni kwezindleko zesikhathi eside ngokunciphisa ukusetshenziswa kwamandla.

Uhlobo Lwezinto

Imishini eyahlukene yakhelwe izinto ezithile, njengamalahle, amalahle, izimpushana zensimbi, noma i-biomass. Khetha umshini ofanele okokusebenza ohlose ukukucubungula.

Amandla Okukhiqiza

Cabangela umthamo odingekayo wokukhiqiza womshini. Imishini ehlukene inamandla okukhiphayo ahlukahlukene, futhi ukukhetha okulungile kuncike ezidingweni zakho zokukhiqiza.

Izidingo Zokucindezela

Kuye ngempahla, ezinye izinhlelo zokusebenza zingadinga ukucindezela okuphezulu ukuze kuhlanganiswe ngempumelelo. Imishini yokunyathelisa ye-Hydraulic iyaziwa ngekhono layo lokusebenzisa ukucindezela okuphezulu.

Okuzenzakalelayo nokulawula

Eminye imishini iza nezici ezithuthukisiwe ezizenzakalelayo nezici zokulawula, okuvumela ukulungiswa okunembile kwamapharamitha kanye nokusebenza kalula.

Izindleko Nesondlo

Cabangela izindleko zokuqala zomshini kanye nezidingo eziqhubekayo zokuwulungisa. Khetha umshini ofanelana nesabelomali sakho futhi osebenzisekayo emandleni akho okunakekela.

I-Biomas Briquetting: Guqula imfucuza yezolimo nezamahlathi ibe amabrikhethi aminyene futhi aminyene amandla ukuze asetshenziswe njengophethiloli.

I-Metal Powder Compaction: Yenza izimpushana zensimbi zibe ama-briquette noma ama-pellets ukuze zigaywe kabusha noma zihanjiswe.

I-Mineral Powder Briquetting: Dala ama-briquettes avela ku-mineral powders okusetshenziswa kwezimboni ezihlukahlukene.

Ukufaka amalahle namalahle: Khiqiza ama-briquette ngenhlawulo yamalahle namalahle azosetshenziswa ekushiseni noma ezinqubweni zezimboni.

Okungenhla isingeniso esiphelele mayelana nezindleko zomshini wokubopha ibhola.Lapho ukhetha umshini wokucindezela ibhola, kubalulekile ukuqonda izidingo ezithile zohlelo lwakho lokusebenza bese ukhetha umshini ohlangabezana nalezo zidingo ngempumelelo nangempumelelo.

Ulwazi olwengeziwe mayelana nemishini yokubopha:

Indlela yokukhetha umshini wokugcwalisa i-briquetting

Uyini umshini wokucindezela ibhola?

Umhlahlandlela Wemishini Yokugcwalisa: Izinhlobo, Izinqubo kanye Nokusetshenziswa

Yiziphi izinhlobo zomshini wokucindezela ibhola

Iyini intengo yomshini wokucindezela ibhola

Iyini isimiso sokusebenza somshini wokucindezela ibhola

Isifinyezo sohlobo lomshini wokucindezela ibhola

Briquetting Machine incazelo, ukusetshenziswa, intengo, isithombe

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com