-

Produkte

-

Toepassing

Kubasebenzi abasebenza phansi efemini, kungakhathaliseki ukuthi banzima kangakanani, kungakhathaliseki ukuthi bakhathele kangakanani, kuwumsebenzi wabo. Okuqukethwe emsebenzini akukwazi ukuthikameza isimo sabo sokusebenza, bese kuthinta ikhwalithi yabo yomsebenzi. Kunalokho, ngaphansi kwethonya lezinye izici zangaphandle, kuzothinta impilo engokomzimba nengokwengqondo yabasebenzi. Kunomonakalo omkhulu, omunye wawo umsindo owenziwa imishini, ikakhulukazi umsindo wemishini emikhulu.

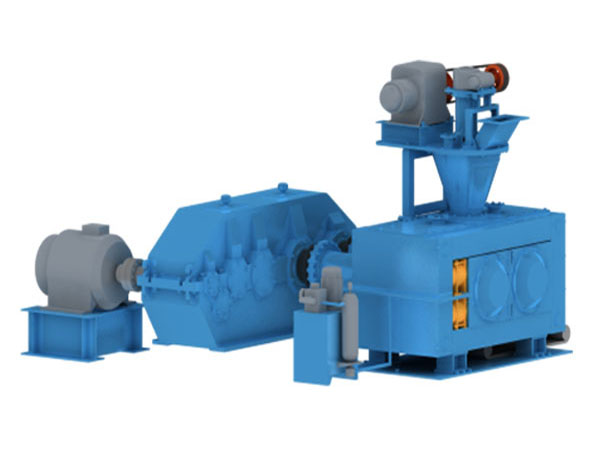

Njengomshini omkhulu wokwakha nemishini, umshini wokucindezela ibhola ukhipha umsindo omkhulu kunezinye izinto ezincane. Ngaphansi kwethonya lomsindo womshini wokucindezela ibhola, ukuzwa kanye nesimo sengqondo sabasebenzi kuzowohloka, futhi umsebenzi ohambisanayo .Ukusebenza kahle kuzokwehla kakhulu, ngakho-ke indlela yokunciphisa umsindo wokucindezela ibhola sekuyinkinga ukuthi bonke opharetha badinga ukuxazulula.

Emishinini eyimishini efana nomshini we-briquetting, umthombo womsindo awuyona into engaphezu komsindo wokungqubuzana wezingxenye ezihlukahlukene, umsindo wezingxenye, umsindo wamagiya, umsindo wama-bearings, njll. Ukuqeda ngokuphelele le misindo kuyiphupho eliyisiphukuphuku, okuyinto engenakwenzeka, kodwa ingazuzwa ngendlela efanele yokunciphisa le misindo.

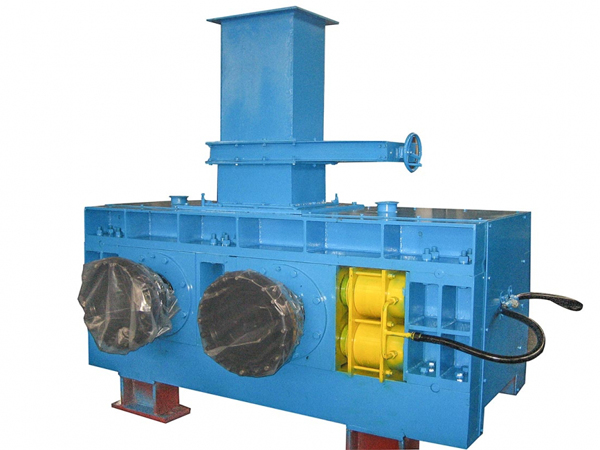

Umshini wokufaka ama-briquetting, njengezinye izinto zokusebenza zemishini, unezikhala zezingxenye. Ngenxa yezikhala phakathi kwezingxenye, izakhi zishayisana phakathi nomsebenzi, okuzodala umsindo. Noma ubani oqonda ukulingana komshini uyazi ukuthi akunakwenzeka ukuqeda lolu hlobo lwegebe, kodwa uma singanciphisa igebe, khona-ke umsindo wokushayisana ohambisanayo uzoncishiswa.

Ukuze unciphise umsindo womshini wokwenza i-briquetting, indlela elula nengenanhlonipho iwukuhlukanisa izingxenye ezithile ezibangela umsindo, njengokuhlukanisa injini. Ukuze uvimbele ukuthi injini ingashisi ngokweqile, injini ingafakwa ngakolunye uhlangothi lodonga ngesikhathi sokufakwa. , Futhi uqinisekise ukugcinwa okubushelelezi, ukuze kuzuzwe umphumela wokuhlukanisa umsindo nokunciphisa umsindo.

Ngomshini we-briquetting, ukuthwala kuyingxenye egijima kuyo yonke imishini. Uma i-bearing esetshenzisiwe iphansi, ingasaphathwa, umsindo wodwa awukwazi ukuhlangabezana nezidingo zomsebenzi, ngakho-ke lapho ukhetha ukuthenga umshini we-briquetting, qiniseka ukuthi uqinisekisa Ama-bearings oyisebenzisayo kukhona okuhle nokubi. I-bearing iba yinde kakhulu uma iba nkulu. Udinga nje ukwazi ukuthi ama-bearings nawo anemisindo engezansi nama-bearings athule. Ungakhetha imishini yama-bearings.

Ukufingqa, lapho uthenga futhi ufaka umshini wokucindezela ibhola, kufanele uqale ukhethe ifektri evamile, njengomshini wokucindezela ibhola okhiqizwe yiLuoyang Zhongyuan Mining Machinery Equipment Co., Ltd., onomsebenzi omuhle, izikhala ezincane phakathi kwezingxenye, kanye nomsindo ophansi ngokufanayo. Ngaphezu kwalokho, izisebenzi zokufaka izimboni ezinkulu ziyaqeqeshwa futhi ziqondiswe, futhi igebe lizoncishiswa ngesikhathi sokufakwa.

Ukunciphisa umsindo womshini wokucindezela ibhola, akwanele ukunciphisa umsindo wemishini, ngoba umsebenzi womshini wokucindezela ibhola empeleni ukucubungula izinto kuwo wonke umugqa wokukhiqiza, ngakho-ke umsebenzi wokunciphisa umsindo kufanele futhi uqhutshwe. ngaphandle ngesikhathi sokuncelisa. . Kweminye imishini emgqeni wokukhiqiza, singabhekana nayo ngokuhambisana nendlela yokunciphisa umsindo yemishini yemishini, kodwa ezinye izindlela ziyadingeka ngesikhathi senqubo yokudla.

Ngemuva kokuthi izinto zichotshozwe yi-crusher, ubukhulu bezinto ezibonakalayo buhlukile. Impahla enkulu ayizinzile ngokwanele enqubweni yokuthutha, izokhiqiza ukugudluka, bese yenza umsindo omkhulu. Ngakho-ke, kuyadingeka ukukhetha impahla enkulu futhi uqhubekele esinyathelweni sesibili. Ngemva kokuchotshozwa kwesibili, faka imishini yokucindezela ibhola.

Ukungqubuzana nokungqubuzana phakathi kwebhulokhi yensimbi nesidlulisi sebhande elidluliselayo nakho kungenye yemithombo yomsindo. Ngaphezu kwalokho, i-metal block nokunye ukungcola kwensimbi kungena emshinini webhola ngokuqondile ngaphandle kokukhethwa, okuzophinde kubangele ukulimala kwesikhumba se-roller. Isizathu.

I-conveyor yebhande lokudla kanye nama-feed bearings kufanele kugcinwe ngesikhathi. Uma umsindo we-bearing unamafutha amancane futhi ugugile, futhi umsindo wokungqubuzana kwebhande ukhishwa ngokulandelana, kungabhekwa "njengokwengeza umlilo" kuyo yonke indawo yokusebenza.

Ngaphezu kokunciphisa okuphuthumayo komsindo endaweni yokusebenza yemishini yokucindezela ibhola, ukunciphisa umsindo ngaphandle kwendawo yokusebenza nakho kuyadingeka kakhulu. Phela, ibhizinisi alikwazi ukuba nomugqa owodwa wokuhlanganisa wemishini yokubumba, kodwa asekhona amanye amahhovisi, izindawo zokuhamba nezokugcina.

Ngaphambi kokufaka umshini wokucindezela ibhola, kunezimo ezingasetshenziswa ukwakha isakhiwo esingenamsindo kusengaphambili ukuze kuhlukaniswe umsindo wokucindezela ibhola ngaphakathi kwesitshalo. Ngesikhathi esifanayo, udonga oluvikela umsindo lungaphinde lubambe inani elithile lomsindo futhi lunciphise ivolumu.

Uma isitshalo kanye nemishini yokucindezela ibhola ifakiwe, i-asbestos nezinye izinto zokuvikela umsindo zingangezwa ezindongeni zesitshalo ukuze kuqinisekiswe ukuthi imithombo yomsindo emincane iphuma ngaphandle kwendawo yokusebenza.

Ngamaphuzu angenhla, kungabonakala ukuthi ukunciphisa umsindo womshini we-briquetting kufanele kuhloswe, futhi umsindo womshini awukwazi ukuqedwa ngokuphelele, futhi ungancishiswa kuphela ngangokunokwenzeka. Kunesidingo futhi sokuqinisekisa ukucinana kokuxhumana phakathi kwemishini, nokunaka ukugcinwa okufanele. Imayini ye-Zhongyuan, umkhiqizi womshini wokubopha i-briquetting, ukukhumbuza ukuthi kuphela ngokunakekela kahle okokusebenza lapho okokusebenza kunganikeza isevisi engcono kithi.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com