-

Produkte

-

Toepassing

I-conveyor isetshenziselwa kakhulu ukuthutha izinto. Inephuzu lokuthi isiqondiso siyashintsha futhi isiqondiso sokudlulisa singashintshwa ngokuguquguqukayo. Sivamise ukuba nama-screw conveyor namabhande, njll. Phakathi kwawo, amabhande ayindlela eyinhloko yokudlulisa izinto eziyinqwaba. Uma sisebenzisa noma sigcina umshini ngendlela engafanele, isihambisi singase singaphumeleli futhi sibangele isikhathi sokuphumula. Uyasazi isizathu sokuphelelwa isikhathi kwesithuthi?

I-screw conveyor inezinzuzo zosayizi omncane we-cross-sectional wawo wonke umshini, ukusebenza kahle kokuvala, ukulayisha amaphuzu amaningi kanye nokuthulula phakathi nendawo, nokusebenza okulula nokugcinwa. Ilungele ukuhambisa izinto eziyimpuphu, i-granular kanye ne-block encane. Isetshenziswa kabanzi ezintweni zokwakha, i-metallurgy, Chemical, amandla kagesi, amalahle, imishini, okusanhlamvu, ukudla nezinye izimboni; akufanelekile ukuthutha izinto ezibolayo, ezibonakalayo, futhi kulula ukuhlanganisa.

1. Impahla inkulu kakhulu

Inkinga: Impahla okufanele idluliselwe inkulu kakhulu, okokusebenza akukwazi ukudlula endaweni elengayo emaphakathi ngokushelelayo, futhi ukumelana nokwenyama endaweni ephakathi nendawo kukhulu kakhulu, okubangela ukuthi isixhumi esihambisa isikulufu sime kungazelelwe.

Isixazululo: yahlulela usayizi wento ngaphambi kokudlulisa ukugwema ukuthi into ibe nkulu kakhulu futhi ibhajwe phakathi nebheyili elengayo, okuholela ekuphelelweni kwesikhathi.

2. Ukuvinjwa kwezinto

Inkinga: Ukuvinjwa kwento ku-screw conveyor nakho kungabangela ukuthi injini igcwale futhi ivaleke.

Isixazululo: Kumelwe sihlanze izinto eziku-screw conveyor, sigcine isihambisi singavimbeli, futhi sifake isicoci sebhande ukuze sigweme ukuvaleka ngenxa ye-viscosity eningi yezinto.

3. Ukulimala kwesici

Inkinga: Ukumelana ne-bearing ephakathi kukhulu kakhulu futhi uphawu lonakele. I-Material engena kwi-bearing ibangela ukuthi ukuthwala kungajikijeli noma ukuthwala konakale.

Isixazululo: Isigxivizo sidinga ukushintshwa, futhi okungavamile endaweni ephakathi nendawo kufanele kuhlolwe ukuze kulungiswe.

4. Ukuthwala okushile

Inkinga: I-reducer bearing ishile, okuholela ekuphelelweni kwesikhathi.

Isixazululo: Faka esikhundleni izingxenye ezintsha ukuze uqinisekise ukusebenza okuvamile komshini.

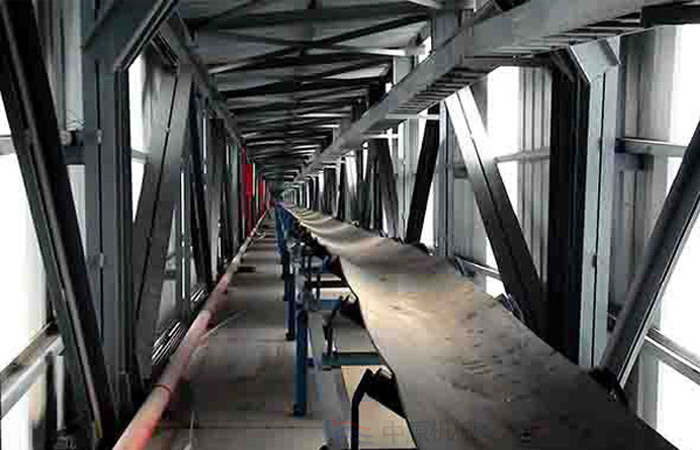

I-conveyor yebhande inezinzuzo zomthamo oqinile wokudlulisa, ibanga elide lokudlulisa, ukusebenza okuzinzile nokuthembekile, ukusebenza kahle okuphezulu, umsindo ophansi, isakhiwo esilula nokugcinwa okulula, futhi ingakwazi ukusebenzisa kalula ukulawula okuhleliwe nokusebenza okuzenzakalelayo. Ilungele ukuthutha impahla eningi noma eqediwe ku-metallurgy, izimayini, amalahle, amakhemikhali, amandla kagesi, izinto zokwakha kanye nezinye izimboni.

1. Ukuchezuka kwebhande

Inkinga: Ukungahambi kahle kwebhande kwenzeka lapho ibhande liphambuka endleleni eliyifunayo. Lena inkinga enkulu engaholela ekulimaleni kwebhande, ukungasebenzi kwemishini kanye nokuchitheka kwempahla. Kunezizathu eziningi zokuphambuka kwebhande, njengokungezwani kwebhande okunganele, umthwalo we-eccentric, ukuhlanganisa okungalungile, ukuphambuka kwengxenye, ukuqoqwa kwezinto ezibonakalayo ezingxenyeni nasezintweni, njalonjalo.

Isixazululo: Isixazululo esingcono ukuthola umsuka wokungahambi kahle kwebhande ukuvimbela inkinga efanayo esikhathini esizayo. Ukuhlola ibhande kungasiza ekuboneni noma yiziphi izinkinga ezingase zibangele ukungahambi kahle kwebhande ukuze kuthuthukiswe isisombululo esifanele ngokusekelwe enkingeni. Uma ibhande lingahambi kahle kancane, umuntu ongenzi lutho oziqondanisa naye angasetshenziswa ukulungisa umgudu webhande nokuqinisekisa ukuthi ibhande lizohlala ligijima liqonde esikhathini esizayo.

2. Imbuyiselo yezinto ezibonakalayo

Inkinga: Uma inani elincane lempahla linamathela ebhandeni, umthumeli uzobuyisela lo mkhuba. Lokhu kungabangela ukuthi impahla yakheke ngaphansi kwebhande lokuthutha, noma kuma-idlers nezigubhu. Izinto ezithile, njengobumba nezinsimbi ezithile, zinamathela ebhandeni kalula kunezinye. Nakuba umthamo wokubuyisela umncane kakhulu, ngokuhamba kwesikhathi eside, kuzoba namathani ezinto eziqoqiwe, okumele zihlanzwe kabili. Ukubuyisela emuva impahla kungadala ukuphepha kanye nezingozi zemvelo, kwenyuse izindleko zokuhlanza, futhi ngokuvamile kuvimbele amasistimu okuthutha ukuthi asebenze esimweni esihle.

Isixazululo: Isixazululo esilula ukufaka izinto zokuhlanza amabhande ukuze kuvinjwe ukuthwala. Izinzuzo zokuhlanza ibhande ngaphezu kokunciphisa izindleko zayo zokutshala izimali zangaphambili. Ukuchitheka kwempahla encishisiwe konga izindleko zokulungisa futhi kudala indawo yokusebenza ephephile. Ngaphezu kwalokho, amabhande ahlanzekile avimbela ukwehluleka kokungenzi lutho ngaphambi kwesikhathi, andisa ukuphila kwebhande, futhi agcine isistimu isesimweni esihle sokusebenza.

3. Ukulimala kwebhande

Inkinga: Ukulimala kwebhande kungabangelwa izici eziningana, ezifana namandla omthelela amaningi, ukungahambi kahle, ukusetshenziswa okungalungile kwezinhlelo zokuvala uphawu noma izihlanzi zamabhande, ukubamba izingxenye kanye nokudonsa kwe-pulley okwanele. Amabhande ayizingxenye ezibizayo zama-conveyors, ngakho-ke imbangela eyinhloko yezinkinga zamabhande kufanele ikhonjwe futhi kuthathwe isinyathelo ukugwema umonakalo ongalungiseki.

Izixazululo: Kunezimbangela eziningi zokulimala kwebhande ngakho-ke izixazululo eziningi ezahlukene. Isibonelo, ukufaka ama-buffer roller noma abakaki endaweni yokudla kungahlakaza umthelela wezinto eziwayo, ngaleyo ndlela kunciphise ukuguga nokudabuka ebhandeni. Ngesistimu yokuvala efanele, ibhande lingavinjelwa ukuthi lingalinyazwa ngezinto ezinamathele. Ngempahla efanele yokugoqa i-roller, ungakwazi ukwandisa ukungqubuzana futhi uvimbele ibhande ukuthi lingasheleli ngaphandle kokulilimaza ngokushesha. Lezi zixazululo zonke zisiza ukunciphisa isikhathi sokulungiswa futhi ngokuvamile zinqunywa ukuhlolwa kwebhande lesibili. Ukuhlolwa kwebhande kungabamba ukulimala okuncane kwebhande, ukuvimbela ukwehluleka okukhulu esikhathini esizayo.

Ngezincazelo ezingenhla, ngikholwa ukuthi nawe unokuqonda okuthile ngezizathu zokuncipha kwesikhathi sabathumeli abajwayelekile. Ungakwazi futhi ukuqonda uma izinkinga ezifanayo zenzeka esikhathini esizayo. Ngaphezu kwalokho, kufanele sithathe izinyathelo zokuphepha ngaphambi kokuthi zenzeke, sigcine ukunakekelwa okuvamile ngesikhathi sokusetshenziswa, futhi sahlulele usayizi wezinto kusengaphambili. noma ingadlula.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com