-

Produkte

-

Toepassing

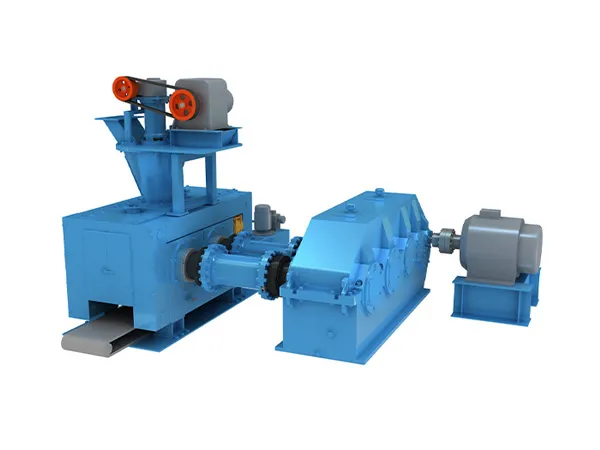

Imishini yokufaka i-briquetting isetshenziselwa ukucindezela imfucumfucu ibe yibhulokhi eqinile, eyaziwa ngokuthi ama-briquette, ukuze kube lula ukulahlwa, ukuthutha, noma ukukhiqizwa kwamandla. Ukufakwa komshini we-briquetting kudinga ukuhlela ngokucophelela ukuze kuqinisekiswe ukuthi usebenza kahle futhi ngokuphepha.

Khetha Indawo:

Khetha indawo eyomile, enomoya omuhle enesisekelo esiqinile.

Qinisekisa ukuthi kunesikhala esanele somshini, indawo yokugcina impahla eluhlaza, namabrikhethi aqediwe.

Qoqa Amathuluzi Nezisetshenziswa:

Izikele, izikulufu, izando, ileveli, nanoma imaphi amanye amathuluzi anconywe umenzi.

Hlola Ukunikezwa kukagesi:

Qinisekisa ukuthi indawo ine-voltage efanele kanye ne-amperage edingwa umshini.

Cela osebenza ngogesi oqinisekisiwe ukuthi ahlole izintambo uma kunesidingo.

Khipha Umshini:

Khipha ngokucophelela umshini emaphaketheni awo.

Hlola noma yimuphi umonakalo okungenzeka wenzeke ngesikhathi sokuthunyelwa.

Hlola Izingxenye:

Qinisekisa ukuthi zonke izingxenye nezinsiza zifakiwe ngokohlu lokupakisha.

Lungiselela Isisekelo:

Qinisekisa ukuthi isisekelo sisezingeni futhi siqinile.

Uma kudingeka, lungisa isisekelo sikakhonkolo ngokuvumelana nemininingwane yomshini.

Misa umshini:

Sebenzisa i-forklift noma i-crane ukubeka umshini esisekelweni.

Qondanisa umshini ngendlela efanele njengokwepulani lesakhiwo.

Bolt Umshini:

Vikela umshini esisekelweni usebenzisa amabhawodi anikeziwe.

Hlola izinga usebenzisa izinga lomoya futhi ulungise njengoba kudingeka.

Xhuma I-Main Power Supply:

Qinisekisa ukuthi umshini uxhunywe kumthombo wamandla olungile.

Landela umdwebo wezintambo womkhiqizi ukuze uthole ukuxhumana okunembile.

Faka Amaswishi Okuphepha:

Faka izinkinobho zokumisa izimo eziphuthumayo namanye amaswishi okuphepha.

Qinisekisa ukuthi zonke izixhumanisi zifakwe kahle.

Xhuma ama-Hydraulic Systems:

Namathisela amapayipi amanzi futhi uhlole ukuvuza.

Gcwalisa i-hydraulic system ngoketshezi olunconywayo.

Xhuma Amasistimu Womoya:

Namathisela amapayipi omoya futhi uqinisekise ukuthi umoya usezingeni elifanele.

Faka futhi Ulungise Izingxenye:

Faka noma yiziphi izinanyathiselwa ezidingekayo njengeziphakeli noma ama-conveyor.

Lungisa izilungiselelo ezifana nokucindezela kokuminyanisa, izinga lokuphakelayo, nezinga lokushisa ngokusekelwe kokokusebenza okuzofakwa i-briquet.

Linganisa izinzwa:

Qinisekisa ukuthi zonke izinzwa zilinganiswe ngendlela efanele.

Hlola iphaneli yokulawula ukuze uthole ukufundwa okunembile.

Ukuqala kokuqala:

Qala umshini ngokulandela imiyalelo yomkhiqizi.

Qaphela noma imiphi imisindo noma ukudlidliza okungajwayelekile.

Hlola nge-Raw Material:

Yondla inani elincane lempahla eluhlaza ukuhlola umshini.

Hlola ukwakheka kwe-briquette okufanele futhi ulungise izilungiselelo njengoba kudingeka.

Gada Umshini:

Qalisa umshini ngokuqhubekayo amahora ambalwa ukuze uqinisekise ukusebenza okuzinzile.

Gada amazinga okushisa, izingcindezi, neminye imingcele yokusebenza.

Yenza Ukulungiswa Kokugcina:

Lungisa umshini ngokusekelwe ekusebenzeni ngesikhathi sokuzama.

Abasebenzi bokuqeqesha:

Nikeza ukuqeqeshwa kwabasebenza ngokuthi bawusebenzise kanjani futhi bawunakekele kanjani umshini ngokuphepha.

Qinisekisa ukuthi zonke izinqubo zokuphepha ziyaqondwa.

Bhala ukufakwa:

Rekhoda zonke izilungiselelo, ukulungisa, nanoma yiziphi izinkinga ohlangabezane nazo phakathi nokufakwa.

Ukunikezwa Kwemisebenzi:

Nikeza umbiko ogcwele wenqubo yokufaka.

Hambisa noma imaphi amamanyuwali, amadokhumenti ewaranti, namanye amaphepha afanelekile eqenjini elisebenzayo.

Setha Umjikelezo Wokulungisa:

Misa ishejuli yokulungisa evamile ngokusekelwe ezincomweni zomkhiqizi.

Bandakanya amasheke ansuku zonke, ukuhlolwa kwamasonto onke, kanye nesevisi yanyanga zonke njengengxenye yesimiso.

Lo mhlahlandlela unikeza umbono jikelele. Kubalulekile ukulandela imiyalelo ethile kanye nezincomo ezinikezwe umkhiqizi womshini wokufaka ama-briquetting ukuze ufakwe ngempumelelo.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com