-

Produkte

-

Toepassing

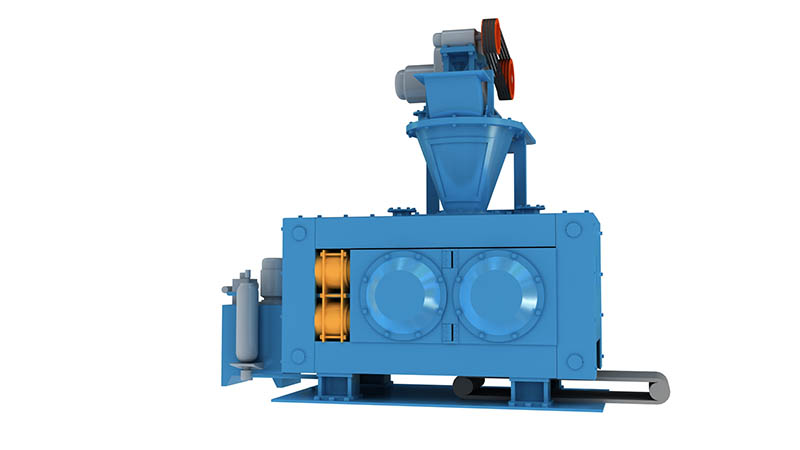

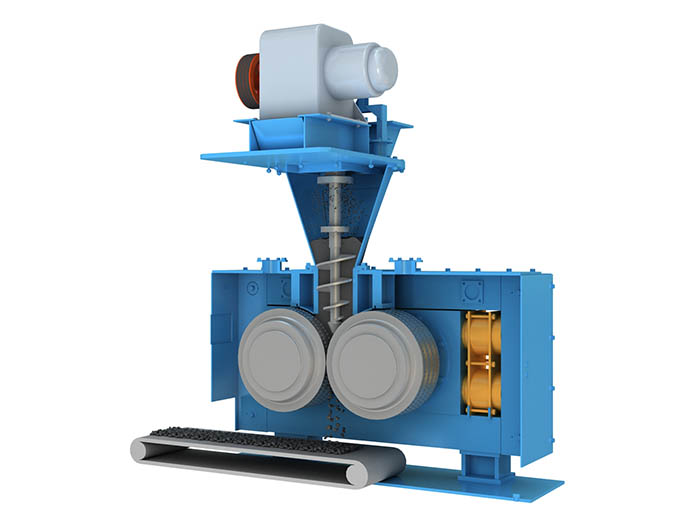

Ekukhiqizeni kwanamuhla kwezimboni, ukuze kugcinwe izinto zokusetshenziswa, imishini ehlukahlukene ezimbonini ezahlukahlukene ivela ngokungapheli. Njengesisetshenziswa esibalulekile sokucubungula nokucindezela nokusebenzisa kabusha, umshini wokucindezela ibhola nakanjani uzoba nokuguga nokuguga okuhlukahlukene okusetshenziswayo. Izingxenye zomsebenzi ezibalulekile emshinini wokucindezela ibhola Izikhumba ze-roller zivame ukushintshwa ngemva kokugqoka.

Isikhumba se-roller siyilungu eliyisilinda elinesokhethi yebhola elimbiwe ongqimbeni olungaphandle olusongwe umgogodla we-roller wokucindezela ibhola. Imvamisa, ukucindezelwa kwezinto kuncike ku-hydraulic drive roller, eyakhiwa isokhethi lebhola lesikhumba se-roller, njengendlela elula kakhulu yokugqoka ibhola. Ukushintshwa kaningi akwamukelekile ku-opharetha, kodwa isikhumba serola sokucindezela ibhola ngemva kokugqoka asikwazi ukuhlangabezana nezidingo zokukhiqiza, futhi asikwazi ukushintshwa ngaphandle kokushintshwa. Kubaluleke kakhulu ukugcina isikhumba se-roller ngesikhathi sokusetshenziswa. I-ball press ethize Iyiphi indlela yokugcinwa kwesikhumba se-roller?

Kunezindlela ezine zokufaka zesikhumba se-roller sokucindezela ibhola. Imishini ye-briquetting ehlukene isebenzisa izindlela ezahlukene, kodwa izindinganiso zokufaka ziyafana. Okokuqala, ukufakwa kwesikhumba se-roller akukwazi ukungahambi kahle. Uma isikhumba se-roller sesivele silahlekile ngesikhathi sokufakwa, khona-ke Ingasaphathwa ukukhiqizwa, ukuma kwebhola kanye nesokhethi esikhumbeni se-roller kufanele kuhambisane, ngaphandle kwalokho izinkinga ezinjengokungabikho kwebhola, ibhola elixekethile, kanye nesimo esingenangqondo esiyindilinga somshini we-briquetting. kuzokwenzeka; ngesikhathi esifanayo, ngenxa yokungalungi kahle phakathi kwesikhumba se-roller kanye nebhola kanye nesokhethi Imiphetho yama-dimples igqoka komunye nomunye, futhi izikhumba ze-roller zizodinga ukushintshwa ngemva kwesikhathi eside.

Insimbi evame ukusetshenziswa yesikhumba se-roller yomshini wokuphonsa we-briquetting yi-65 manganese alloy, insimbi evame ukusetshenziswa esikhumbeni se-roller yomshini wokubumba ibhola we-briquetting yi-92 chromium molybdenum. Izikhumba ze-casting roller azikwazi ukuguga, kodwa zinezindleko eziphansi. Abanye o-opharetha ababi. Akuyona inkinga ukushintsha izikhumba zamarola njalo. Kodwa-ke, opharetha abasebenzisa izikhumba ze-roller ezihlanganisiwe, isikhumba se-roller sihlala isikhathi eside, Kungcono ukungashintshi, kodwa indlela yokugcinwa kwesikhumba se-roller yomshini we-briquetting ayivunyelwe.

Ngemuva kokuthi isikhumba se-roller sifakwe ngendlela efanele, uma ufuna ukunciphisa ukugqokwa kwesikhumba se-roller, kufanele uthathe izinyathelo ezithile zokuzivikela ngaphambi kokuba imishini isebenze. Kumelwe kufakwe uzibuthe ku-conveyor webhande lokuphakelayo ukuze kuvinjwe izinto zensimbi eziqinile ukuthi zingangeni esikhumbeni se-roller futhi zibangele ukuthi isikhumba se-roller sibophe Ukulimala, abasebenzi kufanele bakhethe amatshe ekuthuthweni kwezinto ezibonakalayo, futhi baqinisekise ukuthi usayizi wezinhlayiya impahla ingaphansi kuka-3 mm, ukuze ngenkathi iqinisekisa impilo yesevisi yesikhumba se-roller, ingaqinisekisa futhi ukuthi ukubunjwa kwezinto ezibonakalayo ngeke kubangele izinkinga; Ngaphambi kwalokho, abasebenzi bekufanele bahlole amarola omshini wokucindezela amabhola ukuze babone ukuthi akukho yini ukuxega noma ukuchezuka. Uma lesi senzakalo siqhubeka, kulula ukuphula ama-rollers, futhi ukulahlekelwa akuyona nje isikhumba se-roller.

Idivayisi yokuvikela umshini wokudonsa amanzi ingenye yezinhlaka zomshini wokwenza i-briquetting. Ngenkathi inikeza ingcindezi yokukhiqiza edingekayo yama-roller, ingaphinde ilayishwe kakhulu yi-hydraulic cylinder piston rod lapho okuphakelayo phakathi kwezikhumba ze-roller noma i-metal block kuningi kakhulu. Iphampu ye-hydraulic iyama futhi izinguquko zengcindezi zibangela ukuthi i-accumulator igcine i-buffer, futhi i-valve yokuchichima iyavuleka ukubuyisela uwoyela ukuze isuse i-piston rod, ngaleyo ndlela ikhulise igebe phakathi kwezikhumba ezimbili zamarola. Lolu chungechunge lwezenzo luvumela izinto eziqinile ukuthi zidlule kuma-roller ukuqinisekisa izikhumba ze-roller. Awusekho umonakalo omkhulu.

Uma ufuna ukuthi idivayisi yokuvikela ugesi idlale indima yayo efanele, kufanele wenze umsebenzi wokulungisa ojwayelekile. Emsebenzini, ukunikezwa kwengcindezi yedivayisi ye-hydraulic kumele kube nengqondo, ukushaywa akufanele kube ngokweqile, futhi ngesikhathi esifanayo, izinga lokushisa lamafutha lamafutha we-hydraulic akufanele libe phezulu kakhulu noma liphansi. Ngesikhathi esijwayelekile, uwoyela we-hydraulic kufanele uhlungwe njalo. Uma kukhona ukungcola emafutheni, kulula ukulimaza uphawu , Okubangela ukwehluleka ukunyakaza, ngisho ne-cylinder master izoba nemihuzuko.

Indawo yokukhiqiza ehlanzekile ivumela abasebenzi ukuthi baqinisekise isimo sengqondo esihle sokusebenza ngesikhathi somsebenzi wabo. Ukuhlanzeka kuyadingeka ngemva komsebenzi wansuku zonke. Ngaphandle kokuhlanza phansi, ukuhlanza imishini nakho kungenye yezindlela zokugcinwa kwesikhumba se-roller yomshini we-briquetting. Kukhona uthuli oluningi Kulula ukwenza ukuqoqwa kothuli ezingxenyeni ezisebenzayo zemishini kanye nama-bearings avele. Uma ingahlanjululwa isikhathi eside, izothinta ukuphepha nokukhiqizwa okuvamile, futhi izodala nokulimala kwemishini. Ezinye izinto ezicindezelwa yi-ball press ziyagqwala, kanti abasebenzi bayagqwala, kanti abasebenzi bayagqwala, kanti izisebenzi ziyagqwala. ukulimala kwesikhumba se-roller.

Ekukhiqizweni kwansuku zonke kwebhizinisi, indlela yokugcinwa kwesikhumba se-roller yomshini we-briquetting kufanele ilungile ukuze kuqinisekiswe ukuthi ingxenye esengozini yomshini wokucindezela ibhola ayinabungozi kangako, futhi yandise inzuzo yebhizinisi ngokuzifihla. Izindlela zokulungisa imishini.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com