-

Produkte

-

Toepassing

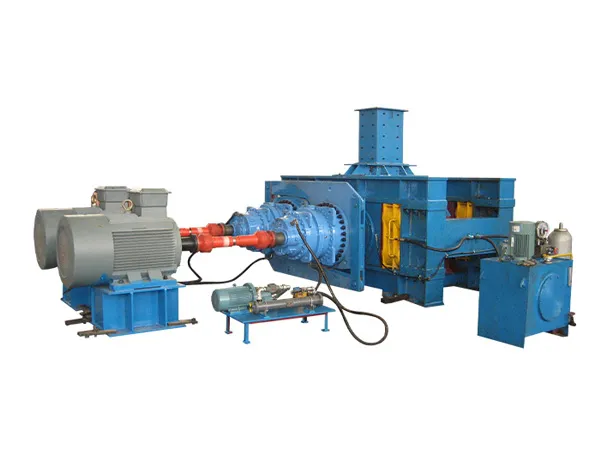

Amaroli okugaya anengcindezi ephezulu asetshenziswa kakhulu embonini ye-ore futhi abuye abe wuhlobo lwe-crusher. Njengemishini eyinhloko yokuchoboza embonini ye-ore, njengoba iyimishini eyinhloko, izosetshenziswa kaningi. Yonke imishini ayinakuhlukaniswa nokugcinwa nokulungiswa kwansuku zonke. Ukugcinwa kahle nokulungiswa kabusha kungakhuphula impilo yesevisi yomshini, futhi ukulungisa kabusha kusenesikhathi kungabona izinkinga kusenesikhathi, ukuze izinkinga ezincane zingabi nkulu, ziphazamise umsebenzi ojwayelekile futhi zidale izingozi.

1. Uma isistimu yokugcoba ithola ukuthi awekho ukuchichima kwamafutha avela ku-labyrinth seal yesihlalo esiphethe, izizathu ezilandelayo zingase zibe njalo:

① ukuntuleka kwamafutha;

② ukwehluleka kwepayipi;

③ iphampu yamafutha iphukile. Uma umbala kanye nezakhiwo zamafutha agelezayo aphuma endaweni yokukhipha uwoyela yesihlalo esingathwele lutho kutholakala ukuthi kushintshile, kungenzeka ukuthi amanzi okupholisa noma enye into yangaphandle iye yahlanganiswa kugrisi wokugcoba.

2. Irola eligudlukayo lihamba ngokungajwayelekile liye ohlangothini oluvundlile. Ngokuvamile, ingcindezi ye-nitrogen accumulator ayanele noma yonakele.

3. Izinga lokushisa likawoyela we-hydraulic liphezulu. Kungaba: ukuvuza okukhulu kwangaphakathi ohlelweni noma iphampu isinesikhathi eside isebenza, futhi isistimu ye-hydraulic idinga ukuhlolwa.

4. Igebe lamarola likhulu kakhulu. Kungase kube nezizathu ezilandelayo:

① Ukuguga okuqinile endaweni yerola;

② Ayikho ingcindezi;

③ Kukhona ukunqwabelana kwezinto phakathi kwama-roller. Idinga ukuphathwa ngendlela efanele.

5. Igebe lamarola lincane kakhulu. Kungenzeka ukuthi kunenkinga ngosayizi we-gap block, noma indawo yenzwa yokufuduka isethwe ngokungalungile.

6. Irola libhajwe. Kungenzeka ukuthi kukhona indaba yangaphandle phakathi kwama-roller, noma kukhona izinto eziningi ezigcinwe phakathi kwama-roller uma uqala.

7. I-roller ayijikelezi. Izizathu zihlanganisa:

① Ukwehluleka kwezimoto;

② Ukwehluleka kokunciphisa.

8. Izinga lokushisa elingaphezulu kwerola liphezulu kakhulu. Kungenzeka ukuthi izinga lokushisa lokuphakelayo liphezulu kakhulu. Kufanele kuthathwe izinyathelo zokulawula izinga lokushisa elikhuphukayo lempahla eluhlaza, ngaphandle kwalokho kuzothinta ukumelana nokugqokwa kwe-roller surface futhi kusheshise ukuguga.

9. Izinga lokushisa elithwalayo liphezulu kakhulu. Izizathu zihlanganisa:

① Izinkinga ngohlelo lokujikeleza okupholisa amanzi;

② Ukutholakala kwamafutha anganele;

③ Inombolo engalungile yamafutha noma mbumbulu.

1. Kudingekile ukuqinisekisa ukuthi i-hopper eqondile emigqeni yokugaya enengcindezi ephezulu inekholomu yempahla ephakeme ngokwanele ukuze ama-rollers amabili ahlale engcwatshwa ngaphansi kwezinto ezibonakalayo. Uma lokhu kungenakuqinisekiswa, imiphumela eminingi emibi izokwenzeka. Okokuqala, ukuphakela okunganele kuzovimbela isilinda esisebenza ngaphansi kwamanzi ukuthi singakhiqizi ingcindezi eyanele yokugingqa izinto, okuholela ekutheni ukusebenza kwempahla kungathuthukisiwe ngemva komshini wokugaywa, okuwukumosha nje kukagesi nezinto zokusebenza; okwesibili, njengoba ikholomu yezinto ezibonakalayo ayikwazi ukwakhiwa, impahla iwa ngokuqondile ebhande futhi igeze i-roller surface, okuzosheshisa kakhulu ukugqoka kwe-roller surface; ngesikhathi esifanayo, ngenxa yesiphakeli esingalingani, kulula ukubangela ukuba i-roller ehambayo iphambuke futhi ilimaze isihlalo esiphethe i-roller.

Ukwengeza, ukudla okunganele, ngezinye izikhathi okungaphezulu futhi ngezinye izikhathi okuncane, kuzophinde kubangele uhlelo lwe-hydraulic ukuthi luqale njalo futhi lufinyeze impilo yezingxenye ze-hydraulic. Ngakho-ke, lapho uhlelo luqalwa, ukuze kwakhiwe ikholomu yezinto ezibonakalayo ngokushesha okukhulu, ibhande lokuphakelayo lebhafa lingavulwa ngokushesha, futhi inani lokuphakelayo lingandiswa ngesikhathi esifushane. Ngemva kokwakhiwa kwekholomu yezinto ezibonakalayo, ingabuyiselwa enanini elishiwo lokuphakelayo.

2. Esimeni esiphuthumayo, umshini kufanele umiswe ngokushesha futhi ibhande elikhuphuka nomfula kufanele livalwe. Uma kungenjalo, phakathi kwamasekhondi ambalwa, okubalulekile kuzogcwalisa i-hopper futhi kuvimbele imbobo yokukhipha ibhande, okubangele ukuthi ibhande lishise ngenxa yokungqubuzana ngesikhathi esifushane. Ngokufanayo, uma ibhande lokukhipha liyeka ngesikhathi sokusebenza, imiphumela emibi izokwenzeka. Ngakho-ke, amaroli okugaya anengcindezi ephezulu kufanele alawulwe ngokuxhunyaniswa namabhande akhuphuka nomfula.

3. Njengoba indima yokugaya i-high-pressure rolls ibaluleke kakhulu futhi isakhiwo siyinkimbinkimbi, kufanele kusungulwe incwadi enemininingwane yokusebenza nokulungiswa ukuze kuqoshwe isimo sokusebenza nokugcinwa kwesisetshenziswa nsuku zonke, okuhlanganisa: isikhathi sokusebenza esiqongelelwe; izinga lokushisa, ingcindezi, ukugeleza, idatha yamanje kanye nenye indawo yokutholwa ngakunye; incazelo yezimo ezingavamile; isikhathi, okuqukethwe, imiphumela kanye nomuntu wesondlo ophethe ukuphatha amaphutha; isikhathi nesikhathi sokugcoba esikhundleni samafutha, njll.

4. Izinga lamafutha okugcoba kufanele lilawulwe ngokuqinile ukuze kuhlangatshezwane ngokugcwele nezidingo zemishini. Isibonelo, abasabalalisi bamafutha yizinto eziningi ezitholakala kwamanye amazwe, ezinembe kakhulu futhi eziphila isikhathi eside ngaphansi kwezimo ezijwayelekile zokusetshenziswa. Kodwa-ke, abakhiqizi abaningi basekhaya bavame ukufaka esikhundleni somsabalalisi ngoba ukungcola kuxutshwe kugrisi, kuvimbe izingxenye ze-valve ku-distributor futhi kubangele ukugxuma. Ngesikhathi esifanayo, njengoba izesekeli zinembile, akulula ukuzilungisa futhi kufanele zishintshwe, okubangela ukuchithwa okukhulu.

5. Ukushintsha kwezinga lokushisa okuthwalayo kanye nokugeleza kwamapayipi amanzi okupholisa ajikelezayo kufanele kubhekwe njalo ukuze kuqinisekiswe ukuthi amanzi okupholisa azungezayo asabalaliswa ngokulinganayo endaweni ngayinye yokupholisa.

6. Ukunikezwa okwanele kwamafutha namafutha we-hydraulic kufanele kuqinisekiswe. I-spare grease kufanele ibekwe eduze kwesiteshi sokusebenza kwamanzi. Uma isiphelile, kufanele ishintshwe ngesikhathi ukuze kuqinisekiswe ukuqhubeka kokukhiqiza.

7. Ukugqoka okuphezulu kwe-roller yesibili kufanele kuhlolwe njalo ngenyanga. Idatha yokulinganisa indawo engaphezulu ngesikhathi sokufakwa nokusetshenziswa kwe-roller kufanele iqhathaniswe ukuze kunqunywe isimo serola, izinga lokuguga, isikhathi sokushintshwa noma izinyathelo zokulungisa.

8. Kuvinjelwe ngokuqinile ukufaka imishini ngamabhuloki ensimbi, imfucumfucu, njll. Ukuxuba udoti ezintweni zensimbi ngeke kuthinte uhlelo lwe-hydraulic kuphela, kodwa futhi kulimaza kakhulu indawo ye-roller, okuthinta ngokuqondile umphumela wokucindezela i-roller.

9. Lapho okokusebenza kulungisiwe noma ngemva kokuba amafutha eshintshwa futhi, izimbobo zokukhipha umoya ku-hydraulic cylinder kanye nesihlalo se-valve ohlelweni lwe-hydraulic kufanele zivulwe ngamunye ngamunye ukuze kukhishwe umoya ohlelweni lwe-hydraulic.

10. Ngaphambi kokuqala ngakunye, i-hopper eqondile kufanele ithululwe kusenesikhathi ukugwema ukushintshashintsha kwengcindezi ohlelweni lwe-hydraulic kanye nokugcwala kwezinto zokusebenza.

11. Usayizi wegebe we-roller side sealing plate kufanele uhlolwe futhi ulungiswe njalo ukuvimbela okokusebenza ukuthi kugeleze phansi futhi kuthinte umphumela wokucindezela i-roller.

Ngemva kokufunda lesi sihloko, ingabe unokuqondisisa okuthile kokuhlolwa nokugcinwa komshini wokugaya onamasondo aphezulu? I-Luoyang Zhongyuan Mining Machinery Manufacturing Co., Ltd. iyakukhumbuza: Ukuze ukwandise impilo yesevisi yomshini futhi kuthuthukiswe ukusebenza kahle komshini, ukuhlola nokugcinwa kwansuku zonke kubalulekile.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com