-

Produkte

-

Toepassing

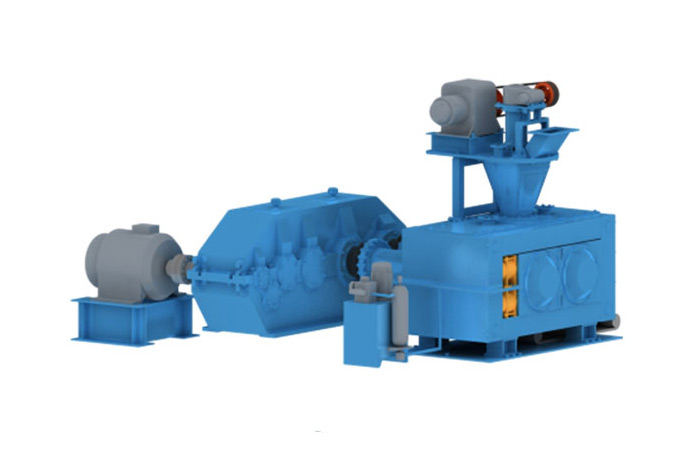

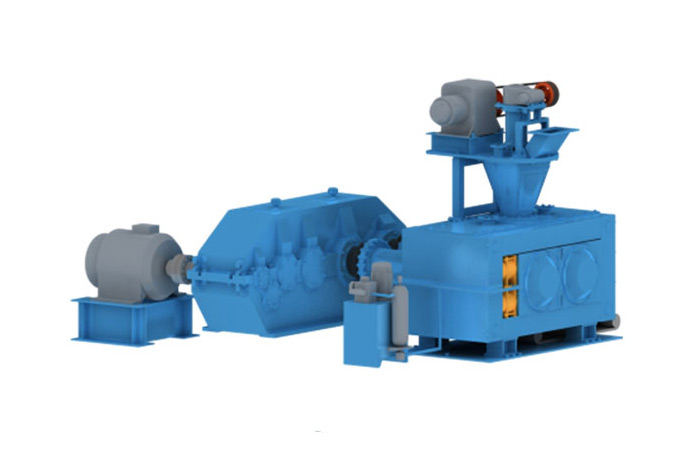

Ngesikhathi sokuthutha, izinto zempushana ezixegayo zijwayele ukuntanta futhi izindleko zokuhamba ziphezulu. Ngakho-ke, ezimweni eziningi, imishini yokubopha i-briquetting isetshenziselwa ukuwacindezela abe amabhola, abese ethuthwa futhi asetshenziswe. Kodwa-ke, lapho ubhekene nezinto ezihlukahlukene, Ukuze wenze ibhola, izingcindezi ezahlukene ziyadingeka, ngakho-ke umshini we-briquetting kufanele ulungiswe. Indlela yokulungisa ingcindezi yomshini we-briquetting?

Ngokwezinto ezihlukahlukene ezicindezelwe umshini we-briquetting, ukucindezela kwesistimu ye-hydraulic nakho kuhlukile. Ingcindezi yesistimu ingalungiswa ngokuya ngesimo sangempela sesayithi. Indlela yokulungisa ithi:

1. Nqamula isifunda sokulawula uhlelo kuqala, khulula i-valve echichimayo, futhi uqinise isibambo sokulungiswa kwe-relay yokucindezela ngesikhathi esifanayo;

2. Vula amandla e-hydraulic motor, umfutho kawoyela kusilinda esidonsa amanzi uyakhuphuka, bheka inani lokucindezela eliboniswa kugeji yokucindezela, lungisa isibambo se-valve yokukhulula ukuze sibe phezulu kunevelu yokucindezela kokusebenza, futhi ukhiye isikhiya se-valve yokusiza. nati;

3. Xhuma iluphu yokulawula i-hydraulic system futhi ulungise inani lokucindezela kwe-relay yokucindezela. Inani lokucindezela lingalungiswa ngokubhekisela kusibonisi segeji yokucindezela. Inani lokucindezela eliphezulu lingasethwa ku-2 ~ 3MPa ngaphezu kwengcindezi yokusebenza, futhi inani lokucindezela eliphansi lingaba ngaphansi kwengcindezi yokusebenza engu-1 ~ 2MPa;

4. Ngemuva kokulungiswa kwe-relay yokucindezela, i-lock nut ilungisiwe futhi ikhiyiwe. Ngalesi sikhathi, i-valve yokudonsa isistimu ingavulwa noma ivalwe ukuze kuhlolwe isimo sokulungisa iphutha. Ngemuva kokuthi konke sekujwayelekile, ukulungiswa kwesistimu ye-hydraulic kuyaqedwa.

1. Ngaphambi kokulungisa ukucindezelwa komshini we-briquetting, hlola ukuthi ukuxhumeka kwazo zonke izingxenye kuxhunywe kahle, noma ngabe amafutha e-tank anele, futhi uqinisekise ukuthi isibambo se-valve yokuguqula i-manual sisendaweni ephakathi.

2. Thuthukisa isondo lesandla sevalvu echichimayo liye ekugcineni (kwesokunxele) ngaphambi kokuqala injini.

3. Ngemva kokuqala i-motor, vula isondo lesandla se-valve echichimayo kwesokudla, bese ubheka ukufundwa kwegeji yokucindezela. Misa ukulungisa lapho ingcindezi yegeji ifinyelela ku-20.5MPa.

4. Ngaphansi kwesisekelo sephampu engami, lungisa isondo lesandla se-valve echichimayo ukuze unciphise inkomba yegeji yokucindezela ukuya emkhawulweni ongaphezulu wengcindezi yokusebenza (hhayi enkulu kuno-19MPa), futhi ukhiye inathi.

5. Uma uhlelo lokusebenza lomshini we-briquetting ludingeka ukukhulula ukucindezela, isibambo se-valve yokubuyisela emuva kufanele sihanjiswe.

Ngokuphathelene nendlela yokulungisa ukucindezela komshini we-briquetting, okungenhla yikho konke okuqukethwe komkhiqizi womshini we-briquetting kuwo wonke umuntu. Ngethemba ukuthi kungaba usizo kuwo wonke umuntu.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com