-

Produkte

-

Toepassing

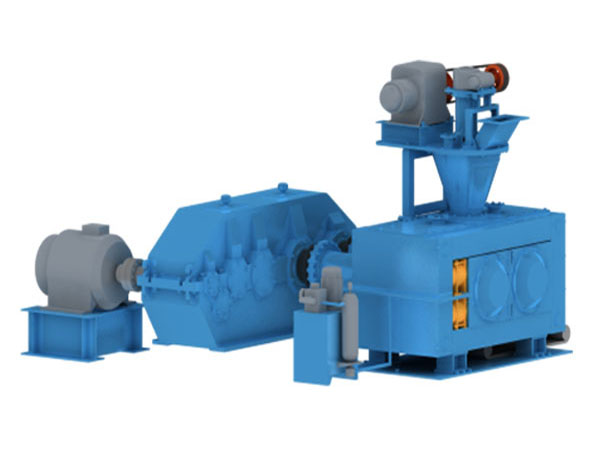

Umshini we-briquetting wakhiwe umhlangano we-shaft ocindezelayo, uhlaka, umshini wokucindezela ngaphambili, isistimu ye-hydraulic, i-coupling, i-reducer, ne-motor. Ngokomsebenzi wengxenye ngayinye, ingahlukaniswa ibe izingxenye ezintathu: ukuphakela, ukudluliswa, kanye nokwakheka. Ingxenye ngayinye ehlukene inethonya elibalulekile ekwakhiweni komshini wokubopha. Imayini ye-Zhongyuan ingumshini wokugcwalisa i-briquetting enengcindezi ephezulu, Umkhiqizi womshini wokugcwalisa umfutho wegazi ophezulu unesipiliyoni seminyaka eminingi ekwakhiweni kwesakhiwo somshini wokubopha, futhi uzochaza ngokuningiliziwe ukwakheka kwalezi zingxenye ezintathu kanye nomgomo wokusebenza we-briquetting. umshini.

1. Ingxenye yokuphakela iwukuba uthole ukudla okwanele ukuze kuqinisekiswe ukuthi impahla ingena ngokulinganayo egunjini le-roller. Ithuluzi lokuphakela ngezikulufu lishayelwa injini elawula isivinini, futhi lizungeziswa i-pulley yebhande kanye nesinciphisi sesikelemu ukuze kuphoqe into ecindezelweyo endaweni yokuphakelayo eyinhloko. Ngenxa yesikhathi esingaguquki senjini elawula isivinini, lapho inani lokucindezela le-screw feeder lilingana nenani lempahla edingwa umsingathi, ingcindezi yokudla engaguquki ingagcinwa ukuze kuzinziswe ikhwalithi ye-pellet. Uma inani lokuphakela likhulu kakhulu, amandla kagesi wedivayisi yokudla azolayishwa ngokweqile; uma inani lokudla lincane kakhulu, ibhola ngeke lakhiwe. Ngakho-ke, amasu okusebenza okunekhono kuyisimo esibalulekile sokuqinisekisa umsebenzi ojwayelekile webhola lokucindezela.

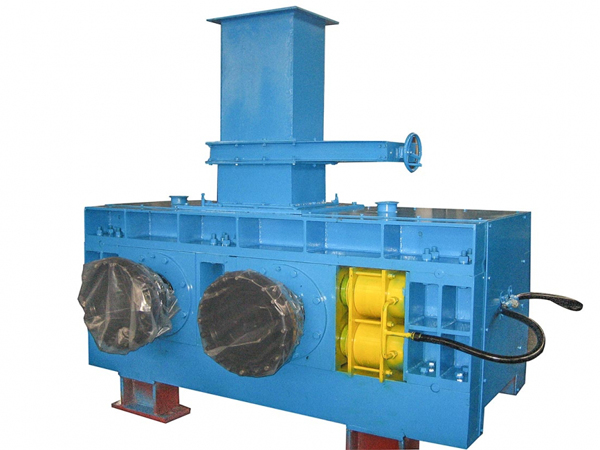

2. Engxenyeni yokudlulisela, uhlelo oluyinhloko lokudlulisela luyi: motor-coupling-synchronous reducer-roller. Injini eyinhloko inikwa amandla yinjini elawula isivinini, edluliselwa kumarola okucindezela amabili nge-synchronous reducer. Kufakwe umshini wokudonsa amanzi ngemuva kwesihlalo esithwalayo esinyakazayo. Idivayisi yokuvikela i-hydraulic isebenzisa ipompo ye-hydraulic ukushayela uwoyela we-high-pressure ku-cylinder ye-hydraulic, okwenza i-piston ikhiqize i-axial displacement. Ihlangano yangaphambili ye-piston rod ihlezi esihlalweni sokuthwala ukuze ihlangabezane nezidingo zengcindezi yokukhiqiza.

3. Ingxenye eyakhayo ibhekisela ikakhulukazi engxenyeni yomshini oyinhloko, futhi ingxenye eyinhloko i-roller ecindezelayo. Uma kukhona ukudla okuningi kakhulu phakathi kwamarola okucindezela amabili noma amabhlogo ensimbi, i-piston rod yesilinda esisebenza ngogesi igcwala ngokweqile, iphampu ye-hydraulic izoma, i-accumulator izovimba ukuguqulwa kwengcindezi, i-valve yokuchichima izovula ukubuyisela uwoyela, futhi i-piston rod izoshintsha Khulisa igebe phakathi kwama-roller okucindezelayo ukuze izinto ezinzima zidlule ku-roller yokucindezela, futhi ingcindezi yesistimu izobuyela evamile, engavikela i-roller yokucindezela emonakalweni. Lo mshini ungalungisa ukucindezela ngokuvumelana nezidingo ze-pressure ball density, futhi ukukhiqizwa kuyavumelana nezimo futhi kuyaguquguquka.

Ukuze wenze okubalulekile kube yibhola ngaphansi kwengcindezi ephezulu, isikulufu sangaphambi kokuminyanisa sisetshenziswa ukuphoqa into ukuthi yakheke ibe maphakathi ne-counter roller. Ngenxa yesivinini esingaguquki kanye nokuzungeza okuhlanekezela, okubalulekile kuyacindezelwa futhi kwakhiwe. Ingcindezi yeyunithi isuka kokuncane kuye enkulu kuze kube umugqa omaphakathi we-counter roller ingu-"0-0". Kuleli qophelo, ingcindezi yeyunithi yokubumba ifinyelela inani eliphakeme. Njengoba i-counter roller iqhubeka nokujikeleza, ingcindezi yokubumba iyaqhubeka iyancipha, futhi ingena esimweni se-ball-off kuze kube yilapho ibhola livaliwe.

Phakathi kwazo, injini eyinhloko inikwa amandla yi-electromagnetic speed regulating motor, edluliselwa ku-shaft yokushayela ngokusebenzisa i-rod-pin coupling ngokusebenzisa i-pulley yebhande, i-cylindrical gear reducer. I-shaft yokushayela kanye ne-drive shaft kuqinisekiswa ukuthi igijima ngokuhambisana namagiya avulekile. Isisetshenziswa esisebenza ngogesi sifakwa ngemuva kwesihlalo esinesihlalo sokwenziwa. Idivayisi yokuphakela ngezikulufu ishayelwa yinjini elawula isivinini sika-electromagnetic, futhi izungezisa i-pulley yebhande kanye nesinciphisi sezikelemu ukuze kuphoqe into ecindezelweyo ingene endaweni yokuphakelayo eyinhloko.

Ngenxa yesici se-torque engaguquki yenjini elawula isivinini sogesi, lapho ingcindezi yesifunzo sesikulufa ilingana nenani lempahla edingwa umsingathi, ingcindezi yokuhlinzeka engaguquki ingagcinwa ukuze kuzinziswe ikhwalithi ye-pellet. Uma inani lokuphakela lilikhulu kakhulu, idivayisi yokuphakela izolayishwa ngokweqile; uma inani lokudla lincane kakhulu, ibhola ngeke lakhiwe. Ngakho-ke, amasu okusebenza okunekhono kuyisimo esibalulekile sokuqinisekisa ukusebenza okuvamile komshini wokonga amandla we-briquetting.

Idivayisi yokuvikela i-hydraulic isebenzisa ipompo ye-hydraulic ukushayela uwoyela we-high-pressure ku-cylinder ye-hydraulic, okwenza i-piston ikhiqize i-axial displacement. Ihlangano yangaphambili ye-piston rod ihlezi esihlalweni sokuthwala ukuze ihlangabezane nezidingo zengcindezi yokukhiqiza. Uma kukhona ukudla okuningi kakhulu phakathi kwamarola okucindezela amabili noma amabhlogo ensimbi, i-piston rod yesilinda esisebenza ngogesi igcwala ngokweqile, iphampu ye-hydraulic izoma, i-accumulator izovimba ukuguqulwa kwengcindezi, i-valve yokuchichima izovula ukubuyisela uwoyela, futhi i-piston rod izoshintsha Khulisa igebe phakathi kwama-roller okucindezelayo ukuze izinto ezinzima zidlule ku-roller yokucindezela, futhi ingcindezi yesistimu izobuyela evamile, engavikela i-roller yokucindezela emonakalweni. Umshini wokuvikela imvelo we-Kaizheng ungalungisa ingcindezi ngokuya ngezidingo ze-pressure ball density, futhi ukukhiqizwa kuyavumelana nezimo futhi kuyavumelana nezimo.

Kungabonakala esimisweni sokusebenza ukuthi ikhwalithi yebhola elicindezelwe elingenalutho lihlobene ngokuqondile nesimo esivunguzayo, isivinini, ingcindezi yangaphambili, njll., lapho ijubane lomsingathi ukuya ku-roller lilungisiwe, ngakho-ke isikulufu sangaphambi kokucindezela. isivinini kufanele silungiseke, futhi ngesikhathi esifanayo, sihlobene nemvelo ye-powder. Usayizi wezinhlayiyana kanye nenqubo ye-pelletizing (indlela eyomile nemanzi) inomthelela omkhulu. Ngokuvamile, ukubumba okumanzi kulula. Ukubumba okomile, ngenxa yesilinganiso esikhulu sokuminyanisa sezinto ezingavuthiwe, kuthatha izikhathi eziningi ukucindezela ukubumba. Ngakho-ke, lapho kusetshenziswa ukubumba okomile, okusha Inqubo yokucindezela yokondla nokubuyisela impahla ingakhiqiza ngokuqhubekayo futhi ngokuzinzile futhi iqinisekise ikhwalithi yamapellets.

1. Impahla ingena emshinini wokwenza i-hopper ngokulinganayo ukusuka emgqonyeni wokugcina ngokusebenzisa imishini yokulinganisa, futhi ilungiswa yisango lokulungisa ku-hopper ukuze lenze impahla ingene ngokulinganayo phakathi kwe-roller.

2. Ingcindezi yokubumba iyunithi yezinto ezicindezelwa ama-roller ngesivinini esingaguquki nokujikeleza okuhlanekezelayo kushintshaniswa kusuka kokuncane kuya kokukhulu, futhi ingcindezi yokubumba ifinyelela inani elikhulu emgqeni ophakathi we-roller. Ngemva kokuba impahla idlule umugqa, ingcindezi yokubumba iyancipha ngokushesha ukuze impahla ingene Isimo sebhola.

Okungenhla konke mayelana nesimiso sokusebenza somshini wokubhoboza. Kuphela ngokuqonda isimiso sayo sokusebenza ngokuningiliziwe lapho umshini we-briquetting ungasebenza ngokuphumelelayo nangokuphepha.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com