-

Products

-

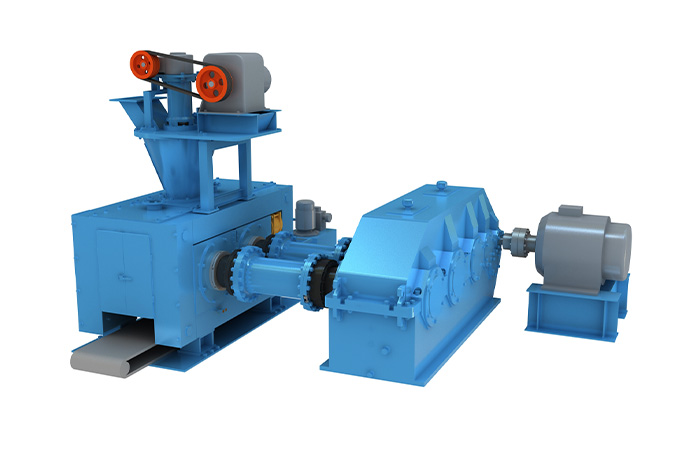

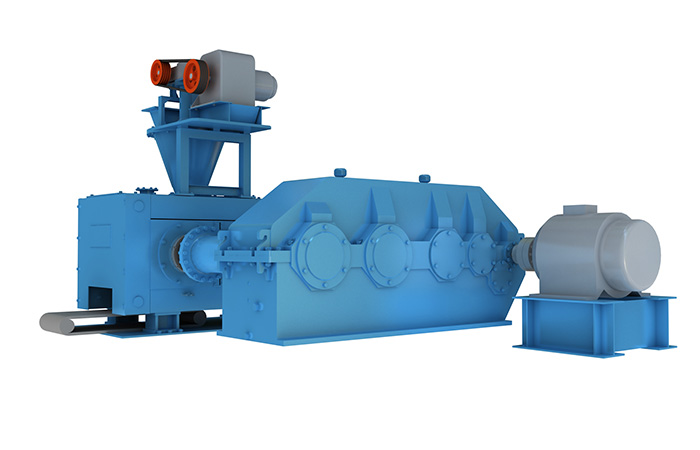

Application

We are all concerned about the output of the ball briquetting machine. If the output of the ball briquetting machine does not meet the requirements, then even saving energy is useless. Next, we will focus on how to increase the pressure of the ball briquetting machine and supporting facilities without changing. The output of the ball machine?

1. The composition of the pressed material, that is, the degree of adhesion is very important and is a key factor in determining the ball-forming effect and productivity. Therefore, before the ball is pressed, the material should be fully dry-mixed to ensure smooth production.

2. The material of the pressure roller is very important. The selected alloy steel material is too single, and long-term use will cause wear and tear, which will have a great impact on production efficiency.

3. The motor and deceleration device of the briquetting machine are also very critical, and a good motor and deceleration device can also indirectly increase the output.

1. During the production process of the briquetting machine, metal and stones should not be allowed to enter the inside of the machine, so as to avoid construction hazards and damage to the structure of the machine;

2. The particle size of the materials used in the briquetting machine must be kept within 3 mm, otherwise it will affect the production efficiency and quality, and also reduce the service life of the briquetting machine;

3. Before starting, it must be ensured that the inside of the machine is empty, and no material is allowed to start;

4. It is strictly forbidden for non-professionals to disassemble and modify the fuselage;

5. It is necessary to regularly maintain and maintain the ball press, and it is strictly forbidden to use it with faults to avoid unnecessary dangers and losses.

1. Be sure to pay attention to the material used in the briquetting machine must not contain metal objects, so as to avoid damage to the roller skin of the briquetting machine.

2. In order to improve the productivity of the briquetting machine, the particle size of the material should be between 90 meshes and 260 meshes.

3. Before using the briquetting machine, let the briquetting machine run idle for several weeks, and start feeding when the briquetting machine reaches the speed. This is to avoid the burning of the motor when the speed of the briquetting machine is not enough at the beginning. damage or bearing damage.

4. The amount of feed must meet the regulations to avoid the unformed briquette caused by insufficient feed or the spheres made by the briquetting machine that are easily broken due to incompact compression.

The above content summarizes the methods of increasing the output of the ball press in detail, and improves the output of the ball press as much as possible from the above three aspects to make its efficiency more stable and efficient.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com