-

Products

-

Application

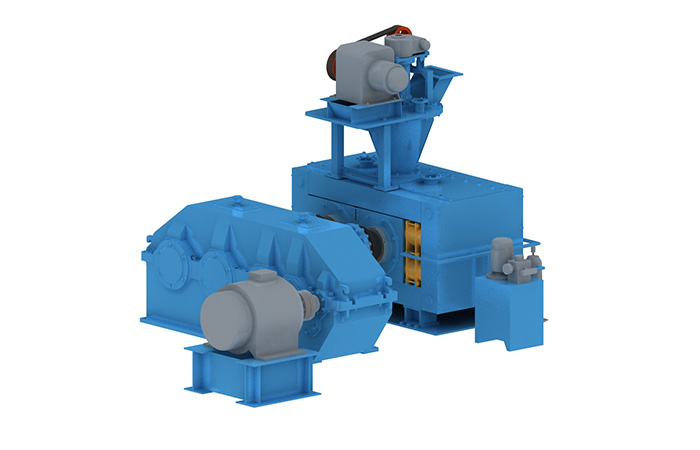

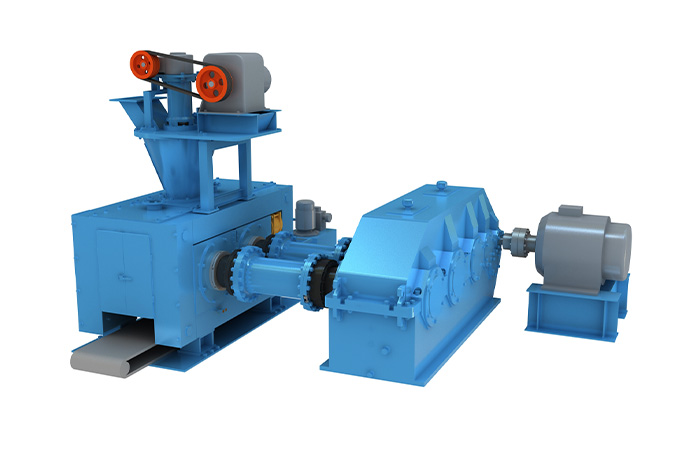

In major mining enterprises, the briquetting machine is an important material forming equipment, and its forming efficiency directly affects the production efficiency of the enterprise. In order to increase production, many enterprises often increase the speed of the briquetting machine. Does the rotation speed really affect the quality of the ball? Does faster revs really increase production? In response to this problem, the briquetting machine manufacturer gave us a detailed introduction.

The forming principle of the briquetting machine is to extrude the falling powdery material in the ball socket through two rollers with the same shape, the same number and the same position on the surface to remove the air between the material particles and make the particles more compact. compact to form pellets with the same shape and size as the ball socket. The pelletizing rate of this molding method is directly affected by the characteristics of the material, as well as the gap between the rollers and the pressure and rotation speed. When all parameters are appropriate, the quality of the pellets to be guaranteed.

As for the quality of the balls only when the parameters of the briquetting machine are appropriate, can the production volume be improved simply by increasing the rotational speed when other parameters are inconvenient? The answer is not necessarily, and whether the speed is too fast or too slow, it has a serious impact on the formation of the ball.

It seems to be a fast process to remove the gas between particles under pressure, but this process also takes time. When there is a lot of air between the particles of the material and the molding pressure is constant, the time it takes for the material to form will be correspondingly slow. At this time, if the speed of the briquetting machine is increased, the molding time will be reduced, then there will be a large amount of air that has not been excluded from the inside of the pellet, and the compactness of the pellet will be insufficient, and there will be virtual balls and loose balls.

The speed of the briquetting machine is slower, although the material particles can gather in the ball socket for a longer time and the pressure is higher. Under normal conditions such as material moisture, binder and briquetting machine pressure, it can effectively avoid false The appearance of the ball will obviously lead to a decrease in production efficiency, an increase in energy consumption and time for the same output, and a decrease in corporate efficiency, which is also what most companies do not want to see.

Since the speed of the briquetting machine is too fast or too slow, it will affect the quality of the balls, does that mean that the output of the briquetting machine is fixed? The answer is obviously not certain. The influence of the speed of the briquetting machine is under the condition that the parameters of other briquetting machines remain unchanged, and it is not impossible to increase the output by increasing the speed.

If you want to increase the output by increasing the speed, the first thing to do is to ensure the adaptability of the material to rapid prototyping, such as whether the binder content can be increased, and whether the moisture content meets the rapid prototyping conditions. Speed, even if more binder is added, the quality of pellets cannot be guaranteed, and it may even affect the subsequent use of pellets.

Increasing the speed of the briquetting machine will reduce the time for the material particles to aggregate into agglomerates, and cannot effectively remove the air between the particles. However, while increasing the speed, the pressure of the briquetting machine can be correspondingly increased, which can speed up the time for air removal and ensure the pellets. density. However, the pressure of the briquetting machine should not be too high, otherwise it will cause premature wear of the roller skin, and it will also increase the heat of the briquetting machine. Overheating is not good for equipment or materials.

Since the forming of the briquetting machine is the extrusion of the material by the rollers, when the rotational speed is increased and the feeding speed remains unchanged, it will cause insufficient material, virtual spheres and hemispheres for each forming. To increase the output by means of pressure, it is necessary to ensure sufficient feeding at the same time to ensure that the quality of the material in each pair of ball sockets meets the requirements of pellet forming.

Regarding the influence of the quality of the speed of the briquetting machine, it mainly depends on whether the materials and the various parameters of the briquetting machine can be matched. , try not to change the speed of the briquetting machine privately, if you really want to increase or decrease the speed, it is recommended to redo the production and debugging to ensure the quality of the balls.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com