-

Products

-

Application

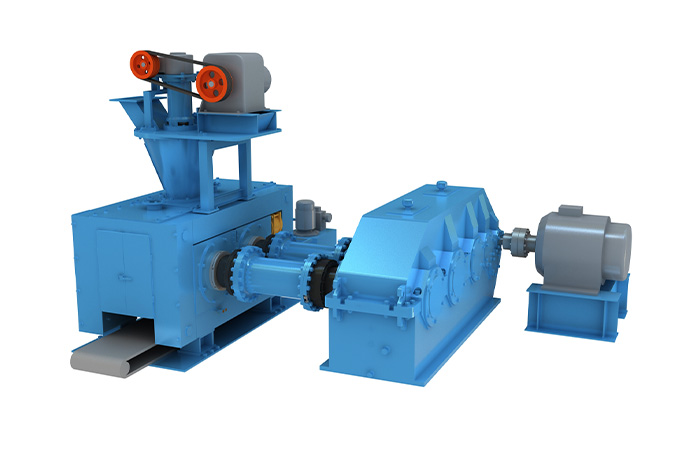

Because the working environment of the ball press is harsh and the work intensity is relatively high, maintenance and inspection are very necessary in the daily use process, especially now that the temperature is gradually rising, more attention needs to be paid, so the ball press equipment needs to be paid attention to in summer .What are the problems?

1. Prevent high temperature

①Before the briquetting machine starts to work, turn the pulley 1-2 circles by manpower, and then start the machine after confirming that the operation is normal. Be sure not to feed the material directly after starting the machine. It can only be done after the ball press is running normally. Generally, this time is about 2-3 minutes;

② During the operation of the ball press, it is necessary to always pay attention to the temperature of the bearing and hydraulic oil to keep it in a good constant temperature state, and always pay attention to whether there is any abnormality in the sound and vibration.

2. Check for wear

①After the briquetting machine is stopped, check whether the bolts are loose and how the wearing parts are worn.

② Always ensure the uniformity and consistency of the feeding of the briquetting machine, not excessive, of course not too small, remember that hard objects such as stones or iron enter the machine;

③ If it is found to be abnormal, stop the machine immediately to check, find out the cause, and confirm whether it is stuck by the object, or the pressure roller or other parts are damaged;

3. Timely heat dissipation

①Although the machine itself has a certain heat dissipation function, it cannot meet the overall heat dissipation needs. Therefore, extra attention is required.

Otherwise, if the heat dissipation is not in place for a long time, the entire ball press will be greatly shortened. lifespan.

②When installing, it is necessary to strictly follow the electrical specifications, and each line must be well run to avoid interference.

③When equipped with fans, try to equip double cooling fans as much as possible, so as to have better effect. You can also put a powerful fan next to the machine, so as to double ensure the cooling problem of the mineral powder briquetting machine, and it will not be caused by heat dissipation. If it is not in place, the machine has problems and stops running.

①In order to ensure the normal production of the ball press and the service life of the machine, special personnel should be assigned to use, maintain and repair.

②The gear oil of the reducer in the ball press device should be replaced quarterly. to ensure the normal operation of the equipment.

③Gear oil should be added to the gear chamber of the ball press twice per shift.

④The bearings of the ball press should be greased once a year.

⑤ Do not open the ball press for a long time, and clean all the remaining materials.

⑥Worn parts should be replaced or repaired in time.

The above article summarizes in detail the problems that need to be paid attention to in the summer. I hope it can help everyone. If you have any other questions about the ball press, please leave a message to us~

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com