-

Products

-

Application

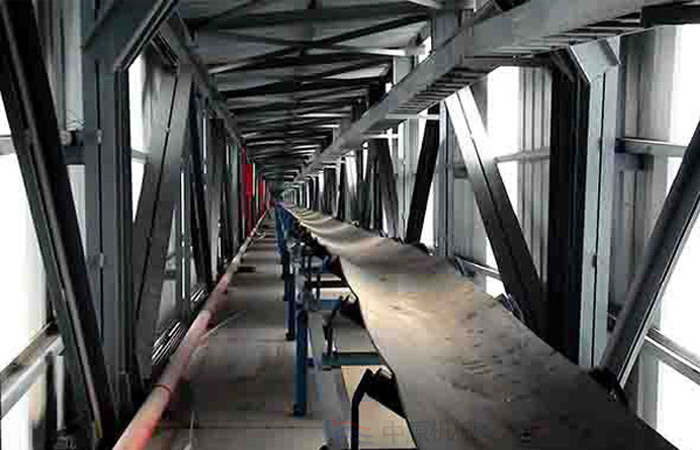

In the production activities of mining, metallurgy, coal, machinery, electric power and other industries, various types of conveying equipment are often used. Belt conveyor is one of the most widely used equipment. Belt conveyor has reliable operation and high degree of automation. The characteristics of large conveying volume, long conveying interval and convenient maintenance are the equipment that must be used by major manufacturers to set up rhythmic and high-efficiency product production lines.

As we all know, belt conveyors are often subject to various wear and tear during work due to the long time, large conveying capacity, and long-distance transportation, and the service life of belt conveyors is often greatly reduced. Therefore, according to the structural characteristics of the belt conveyor, the editor has researched and sorted out a variety of methods to improve the life of the belt conveyor, hoping to help you.

Doing a good job in the daily maintenance of the belt conveyor can reduce the probability of failure of the belt conveyor during transportation. It can also increase the life of the belt conveyor while improving the efficiency of the belt conveyor. The daily maintenance of the belt conveyor mainly includes the following aspects:

1. Check whether the state of the motor reducer is normal and whether it can work normally.

2. Check the connection of each fastener of the equipment for looseness.

3. Check whether the tension of the conveyor belt is in good condition and whether it can run normally.

4. Check the surface of each part of the conveyor for residual materials.

5. Whether the idler runs flexibly and without deformation.

6. Check the lubrication effect of each electronic component and replace it regularly.

1. Protection: The protection of the belt conveyor mainly refers to the protection of the impact of the external environment on the belt conveyor, such as adding a protective cover to reduce the impact of rain, frost and other bad weather on the belt conveyor.

2. Prevention: We not only need to prevent common failures of belt conveyors, but also prevent the state of belt conveyors before, during and after use. For example: check the line, each fastener, the lubrication of each part, the status of each component, etc. before use; prevent materials, conveyor status, and transportation conditions during use; after use, prevention is to ensure that the next time you use it, The belt conveyor can be started and used normally.

3. Maintenance and repair: In the process of use, it is inevitable to encounter various failures. Regular maintenance and repair of the belt conveyor can greatly extend the working time of the belt conveyor and improve the life of the belt conveyor. .

4. Replacement parts: For parts that often have problems or cannot be repaired, they should be replaced in time to improve the service life of the belt conveyor.

The above content mainly introduces how to improve the life of the belt conveyor, hoping to help users in the mining, metallurgy, and coal industries to better use the belt conveyor. If you still need to know more related skills, you are welcome to call or online consultation!

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com