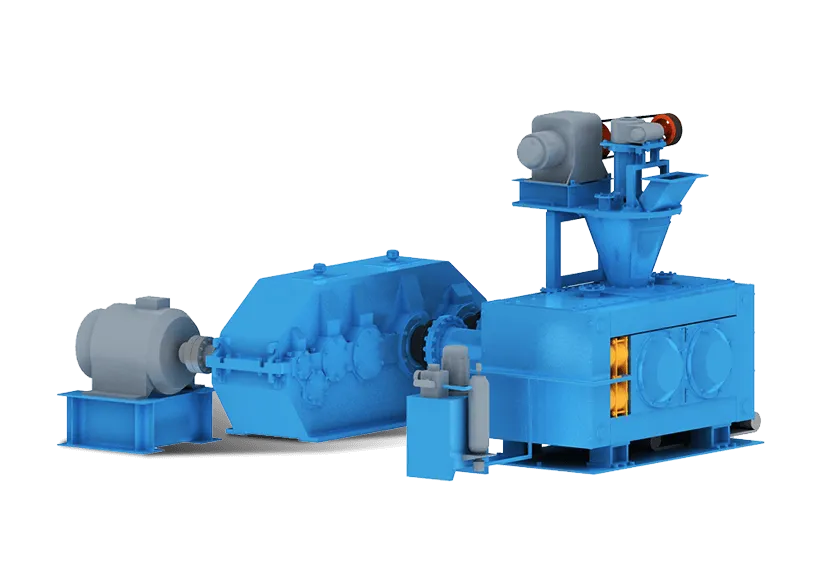

Briquetting Machine Manufacturers from China

-

Products

-

Application

Briquetting machines are used to convert various types of industrial and agricultural waste materials into solid fuel briquettes. These machines compress the waste material using high pressure and heat, creating briquettes that can be used as a fuel source for heating or cooking.

Briquetting machines come in various sizes and types, ranging from small manual machines to large, fully automated systems. They can be classified into two main types: super highpressure briquetting machine, high pressure briquetting machine, medium pressure briquetting machine and tesing briquetting machine.

Metallurgical Industry Material Briquetting

Metallurgical Industry Material Briquetting

In the metallurgical industry materials, you will see the types of materials,which could be used by ZY high-pressure briquetting machine.You can quickly match the equipment that fits your material. Metallurgical auxiliary briquetting machine are mainly used for pressing dry powder and particles without moisture and not easy to form , such as slag after lime block screening, light burnt magnesium powder, light burnt dolomite powder, refractory materials, metallurgical auxiliary materials, aluminum ash, aluminum scrap,etc., The metallurgical auxiliary ball press pressure could be adjusted as needed.

Read more >>

Chemical Industry Materials Briquetting

Chemical Industry Materials Briquetting

Chemical industry materials briquetting is the process of compressing waste materials generated during the production and processing of chemicals into briquettes of a uniform size and shape. The briquettes can be used as a source of fuel or as a raw material for further processing.

Read more >>

Coal Industry Briquetting

Coal Industry Briquetting

Coal is a solid flammable mineral that has been buried in the ground and has undergone complex biochemical and physicochemical changes. In the coal industry materials, you will see the types of materials,which could be used by ZY briquetting machine.You can quickly match the equipment that fits your material.

Read more >>

Refractory Briquetting

Refractory Briquetting

In the refractory briquetting, you will find all kinds of ZY’s high-pressure ball presses that can quickly match the machine that suits your materials.Various kinds of refractory materials could be pressed by our briquetting machine. There are many options for the shape of final briquettes pressed by our ball press, such as round, oval, drip and polygon,etc. Due to the different requirements of final ball and socket in different customers and regions, we can design and customize them according to different materials. The important goal of the ball press is to press and shape various materials and compress them into briquettes of various sizes to make them easy to store, carry and cast.

Read more >>

Company Profile

Research and development, production, sales as a whole

Focus on people

A large number of professional and technical personnel

Our History

Deep industry for more than 30 years

Capacity

Advanced equipment, strong production capacity

The company was founded in 1986

We have 32 technicians

China market share

CNC machining equipment

How to increase output of briquetting machine

Briquetting machines are widely used in industries such as biomass fuel production, metal recycling, and coal processing to compact raw materials into dense, uniform briquettes. However, achieving higher output while maintaining quality and efficiency can be a challenge due to factors like raw mater...

Briquetting Machine Troubleshooting Guide: Common Problems and Solutions

Briquetting machine is an important equipment widely used in metal recycling, wood chip compression, straw molding and other industries. However, in the process of daily use, the briquetting machine may encounter a variety of faults, affecting normal production. This article will provide correspondi...

What are the main applications of briquetting machines?

Briquetting machines, also known as briquette presses, are used to compress loose materials into compact, uniformly sized briquettes. These briquettes have a variety of applications, making briquetting a valuable process across several industries. Briquetting Machine Applications ...

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com