-

Products

-

Application

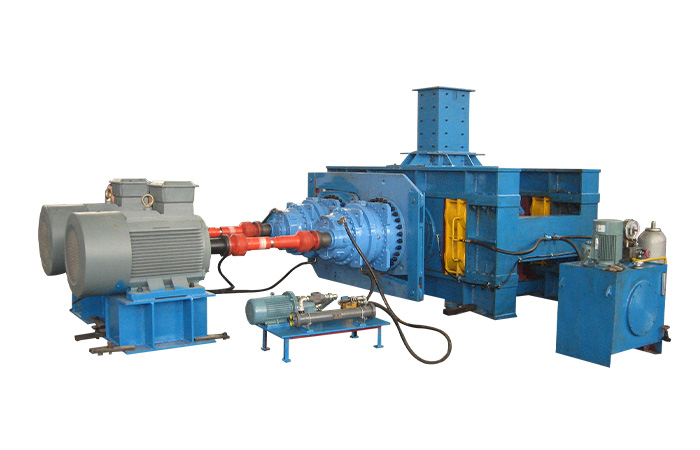

The high pressure grinding rolls is a new type of high-efficiency equipment developed by applying the lamination pulverization mechanism. It is a typical equipment used in the world for the crushing and grinding of non-ferrous mines and oxidized pellets. The high pressure grinding rolls can improve the efficiency of the mineral processing process. It is recognized as the advanced crushing and grinding equipment and has been rapidly promoted. This article will introduce the five major advantages of high pressure roller mills.

The high pressure grinding roll makes full use of the working mechanism of lamination and crushing, and its energy utilization rate is very high. Compared with conventional extrusion ultrafine crushers and mills, the crushing probability and grinding characteristics are greatly improved. Other grinding processes are significantly reduced, and the product contains more fractions that meet the particle size requirements of the final ground product.

For the high pressure roller mill, it is better that the rolled material contains a certain amount of moisture (less than 90%), which can not only form a better self-generating roller fabric pad, but also improve the working life of the extrusion roller. The currently used cemented carbide stud roll surface not only wears very little, but also has a roll surface life span of 7000~30000h.

When dealing with minerals, high pressure can cause minerals to be pulverized along the interface according to the difference in composition properties, which increases the degree of dissociation of minerals. During exudation operations, cracks and fissures on the particle surface and within the particle allow the infiltration of exudate, thereby improving product grade and recovery of useful minerals.

Due to the compact structure, light weight and small size of the high pressure roller mill, its installation location occupies less space. Because the grinding action mainly occurs under the mutual extrusion between the two rollers, the extrusion force generated is mainly borne by the frame, and the load on the foundation is small, so compared with the mill and other equipment, a lot of basic investment can be saved .

Due to the use of lamination crushing mechanism, the material is enclosed in the closed space of the roller and the feeding device, and is crushed by static pressure, generally without impact and material splashing, so the vibration and noise of the equipment are low, which improves the working environment of workers .

The above content is related to the introduction of the advantages of high pressure grinding rolls. High pressure grinding rolls have been widely used in the crushing of the cement industry, the granulation in the chemical industry, and the fine grinding of pellets to increase the specific surface area. It is used for the crushing of metal ore to achieve production practices for different purposes such as simplifying the crushing process, more crushing and less grinding, improving system production capacity, improving grinding effect or sorting indicators.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com