-

Products

-

Application

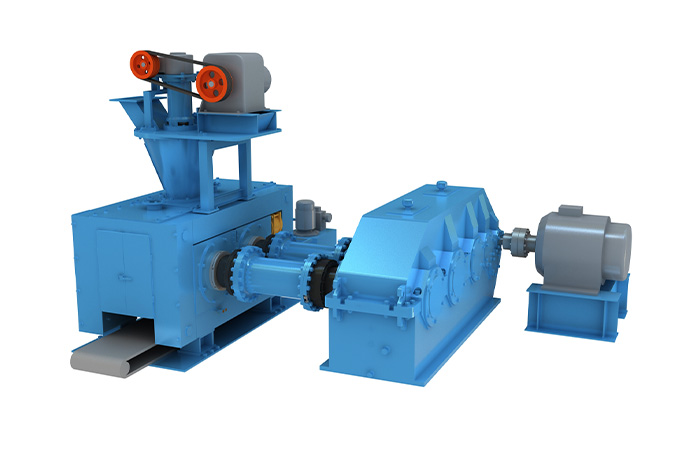

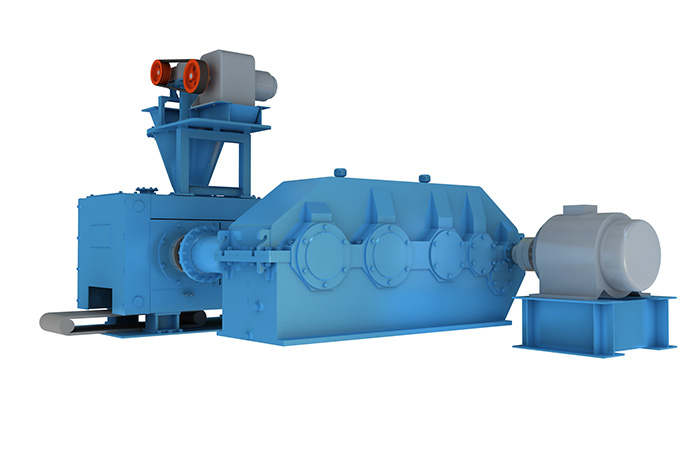

A ball press machine, also known as a ball press or a briquette press, is a mechanical device that is used to press various powdery materials into ball-like or briquette-shaped products. These machines are commonly used for converting coal dust, charcoal powder, coke fines, mineral powder, and other materials into briquettes that can be burned for fuel, used in various industrial applications, or even for household use in cooking stoves or heating.

The process typically involves feeding the raw material into a hopper, where it is compressed and shaped using rollers or a hydraulic press system. The pressure applied helps bind the particles together and form a compacted ball or briquette. Depending on the machine's design, there might also be options for adjusting the pressure, shaping, and sizing of the final product.

Ball press machine types

Hydraulic Ball Press Machine: This type of machine uses hydraulic pressure to compress materials into briquettes. It typically consists of a hydraulic system that generates high pressure, allowing for the efficient compression of materials.

Mechanical Ball Press Machine: Mechanical ball presses use mechanical force, usually generated by a screw or piston mechanism, to press materials into briquettes. These machines are often more compact and require less maintenance compared to hydraulic presses.

Roller Press Ball Machine: Roller press ball machines utilize the principle of two counter-rotating rollers to compress materials into briquettes. The material is forced between the rollers, and the pressure generated causes it to form solid briquettes.

Screw Extruder Ball Press Machine: Screw extruder presses are commonly used for materials like charcoal, coal dust, and biomass. They work by forcing the material through a tapered screw in a heated chamber, resulting in the formation of briquettes as the material cools and solidifies.

Pillow-Shaped Ball Press Machine: This type of machine is designed to produce pillow-shaped briquettes. The material is fed into a mold with two opposing rollers that compress it into the desired shape.

Honeycomb Coal Ball Press Machine: Honeycomb coal presses are used specifically for coal or charcoal briquettes with a honeycomb-like pattern. The machine utilizes a punching mechanism to create holes in the briquette, allowing for better airflow during combustion.

Dry Powder Ball Press Machine: Dry powder ball presses are designed for materials that are dry and powdery, such as metal powders, mineral powders, and other chemical powders. These machines use pressure to compact the powders into solid briquettes.

Mineral Powder Ball Press Machine: This type of machine is used to press mineral materials into briquettes, typically for the purpose of metallurgical processes or creating value-added products from mineral powders.

Charcoal Ball Press Machine: Charcoal ball presses are designed specifically for producing charcoal briquettes. They often incorporate special molds and mechanisms to shape the briquettes and ensure consistent quality.

Other Specialized Ball Press Machines: Depending on the specific application, there are various specialized ball press machines designed for different materials and shapes.

Ball press machines are used in various industries such as metallurgy, chemicals, refractory, and more. They offer a way to recycle and utilize waste materials and reduce their volume, making them easier to transport and store. The resulting briquettes are often more convenient to handle, transport, and store compared to loose powders.

These machines can come in different sizes and configurations, ranging from small manual presses to large automated systems. The choice of machine depends on the specific requirements of the materials being processed and the scale of production.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com