-

Products

-

Application

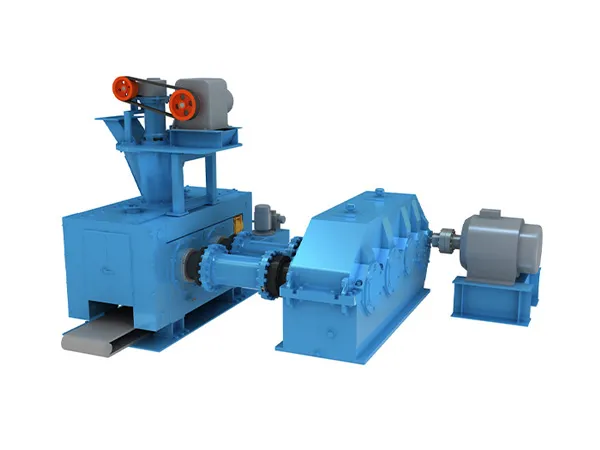

In the field of industrial production, briquetting machine as a kind of equipment to convert powdered materials into pellets, its performance and finished product quality are crucial to the whole production process. The water content of the material is one of the key factors affecting the balling effect, which is directly related to the strength of the pellet, the molding rate and the efficiency of the subsequent processing. In this article, we will discuss how to accurately control the water content of briquetting machine materials to optimize the production process and improve product quality.

Water content is crucial to the working effect of briquetting machine. The right amount of water can be used as a lubricant to reduce the friction between materials and improve the molding efficiency. At the same time, moisture also helps to improve the strength and stability of the pellets. However, too much or too little moisture can negatively affect the balling effect. Therefore, accurate control of moisture content is the key to ensure the normal operation of the ball press.

Too much water: when the water content of the material is too high, the ball will easily become fluffy and weak, with insufficient strength, which is difficult to meet the requirements of industrial applications.

Too little moisture: on the contrary, if the moisture is not enough, the bonding force between the materials will be weakened, resulting in easy crumbling of the pellets, affecting the molding effect.

Pre-treatment: Before the material enters the ball press, its moisture content can be adjusted by pre-treatment such as drying or wetting.

Mixing control: In the mixing process, accurate control of water addition is a common method to control the water content.

Real-time monitoring: Use the water content monitoring equipment to monitor the water content of the material in real time so as to adjust it in time.

Different materials and different briquetting machine models have different requirements for water content. Generally speaking, the water content needs to be determined according to the nature of the material and the specific requirements of the briquetting machine. Usually, the excellent range of water content is between 5% and 15%, but this range needs to be determined by experiment and practice.

The ratio of materials will also affect the control of water content. Different materials have different water absorption and binding properties, so the ratio needs to be adjusted according to the characteristics of the material to achieve excellent water content.

In practice, several tests may be needed to determine the excellent water content. After each adjustment, it is necessary to observe the balling effect, such as the strength, shape and size of the pellet, as well as the working pressure of the briquetting machine.

In addition to water content, there are other process parameters such as pressure, temperature and material particle size will also affect the balling effect. These parameters need to be considered comprehensively to achieve excellent briquetting results.

Environmental factors such as humidity and temperature will also affect the moisture content of the material. In different seasons and regions, it may be necessary to adjust the water content control strategy.

Briquetting machine plays an important role in industrial production by converting powder materials into pellets. The control of the moisture content of the briquetting machine material is crucial to ensure the effective operation of the briquetting machine and the quality of the finished product. Too high moisture content will lead to fluffy and weak pellets, while too low will make the pellets easy to break. Therefore, it is of great significance to accurately adjust the water content of materials through pretreatment, mixing control and real-time monitoring to achieve excellent molding effect and pellet strength, which is important for improving the performance and product quality of the ball press.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com