-

Products

-

Application

In modern industrial production, briquetting machine play a key role in converting powdered materials into pellets with specific shapes and sizes. This transformation not only improves the transportation and handling efficiency ofthe material, but is also often a pre-step for certain chemical reactions or sintering processes. The performance and efficiency of a briquetting press depends heavily on the design of its drive train. In this article, we will discuss in depth the transmission methods of ball presses, analyze their features, advantages and applicable scenarios, and provide industrial users with important references when selecting and applying ball presses.

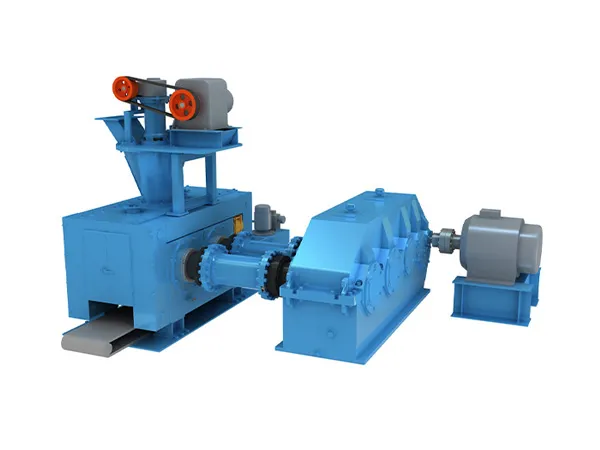

This transmission mode drives the hardened gear reducer through the motor, the low-speed output shaft of the reducer is parallel to the double shaft, through the gear coupling to drive the ball roller relative operation. This type of transmission is suitable for dry powder molding and can provide stable roll rotation and long gear life. Due to its high torque and high line pressure, this type of transmission is very popular in metallurgy, refractory materials and other industries. The ball roller of this transmission mode has stable rotation, long gear life, high transmission torque, and the line pressure of roller surface is up to more than 100KN.

This is a common drive mode of briquetting machine in the current market. The motor through the reducer will transfer the power to the single shaft, and then through the coupling to drive a pair of large gears on the ball roller shaft relative movement. This form of suspended gear is widely used because of its simple structure and lower cost. Because of its simple structure and low price, it is widely used in China.

In order to improve the transmission torque and production volume, some manufacturers will be suspended gear to gear box. This improved transmission mode in maintaining relatively low cost at the same time, improve the transmission efficiency and production capacity of the equipment, has been gradually promoted in the domestic market. Improved transmission mode that is the hanging gear to gear box, increasing the transmission torque, improve production capacity, the price is much lower than the double output shaft form.

Open transmission mode is the motor is directly connected to a few open gears, this transmission mode structure is simple, low-cost, but in the small test or very low production use. Due to its low efficiency and stability, this transmission mode has been gradually eliminated in the market. Open transmission mode, that is, the motor directly drives a few open gear transmission, in small test or very low yield use, has been phased out in the domestic market.

To summarize, there are various transmission methods of briquetting machine, including motor-driven hardened gear reducer, single-shaft reducer transmission, improved gear box transmission and open transmission method, each of which has its own special advantages and limitations. Choosing the right transmission method can not only improve production efficiency, but also reduce energy consumption and maintenance costs.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com