-

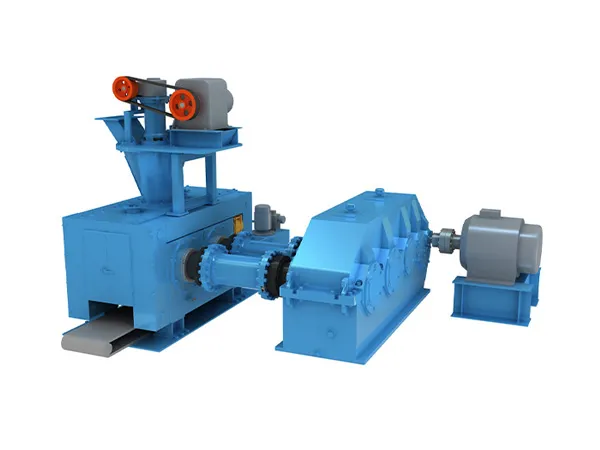

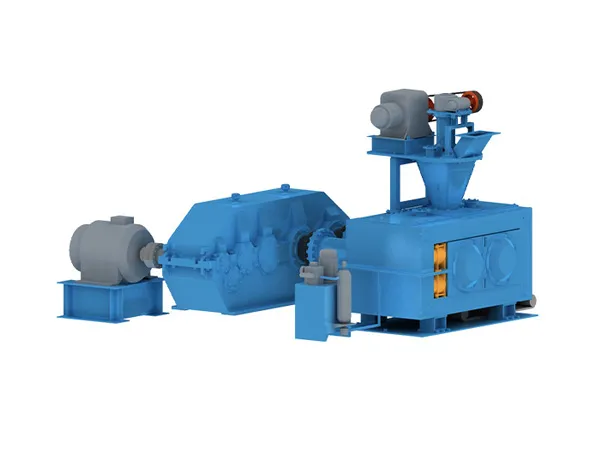

Products

-

Application

Briquetting machine is an important equipment widely used in metal recycling, wood chip compression, straw molding and other industries. However, in the process of daily use, the briquetting machine may encounter a variety of faults, affecting normal production. This article will provide corresponding solutions to common problems, to help users efficiently maintain the equipment.This guide covers common problems encountered with briquetting machines and their respective solutions. It's divided into categories based on the area of the machine where the problem originates.

Problem: Machine won't start/operate.

Possible Causes:

Power Supply Issues: No power reaching the machine.

Emergency Stop Engaged: Emergency stop button is pressed.

Overload Protection Triggered: Machine overloaded and tripped a circuit breaker.

Safety Interlocks: Safety guards or covers are open, disabling operation.

Control System Malfunction: PLC, control panel, or wiring issue.

Motor Failure: Motor is damaged or burnt out.

Solutions:

Check Power Source: Verify power cables, breakers, and voltage.

Disengage Emergency Stop: Ensure the emergency stop button is released.

Reset Overload: Locate and reset the tripped circuit breaker or overload relay.

Check Safety Interlocks: Ensure all guards and covers are properly closed and secured.

Inspect Control System: Check wiring connections, PLC status lights, and consult the machine's manual for error codes. Consider calling a qualified electrician or technician.

Test Motor: Use a multimeter to check the motor windings for continuity and insulation resistance. If faulty, repair or replace the motor.

Problem: Machine stops suddenly during operation.

Possible Causes:

Material Blockage: Obstruction in the feeding system, die, or outlet.

Overload Protection Triggered: Sudden increase in material density or feed rate.

Low Hydraulic Oil Level (if applicable): Insufficient hydraulic pressure.

Sensor Malfunction: Faulty sensor triggering an emergency stop.

Electrical Fault: Short circuit or loose connection.

Solutions:

Check for Blockages: Inspect the feeding system, die, and outlet for obstructions. Clear any blockages.

Reduce Feed Rate: Decrease the material feed rate to prevent overloading.

Check Hydraulic Oil Level: Inspect the hydraulic oil reservoir and add oil if needed.

Inspect Sensors: Check sensor wiring and function. Replace faulty sensors.

Inspect Wiring: Check for loose connections and damaged wiring. Consult an electrician.

Problem: Excessive noise or vibration.

Possible Causes:

Loose Components: Bolts, screws, or other fasteners are loose.

Bearing Failure: Worn or damaged bearings.

Misalignment: Improper alignment of moving parts.

Material Type: Processing a material that is not suitable for the machine.

Foundation Issues: The machine is not properly mounted or supported.

Solutions:

Tighten Fasteners: Inspect and tighten all bolts, screws, and other fasteners.

Inspect Bearings: Check bearings for wear, play, and lubrication. Replace damaged bearings.

Check Alignment: Use shims or other methods to properly align moving parts.

Consult Manufacturer: Verify the material being processed is suitable for the machine.

Secure Foundation: Ensure the machine is properly mounted and supported on a stable foundation.

Problem: Uneven or inconsistent feeding.

Possible Causes:

Hopper Empty or Low: Insufficient material in the hopper.

Bridging or Arching: Material is sticking together and forming a bridge in the hopper.

Feeder Malfunction: Auger, screw conveyor, or other feeding mechanism is not operating properly.

Material Properties: Moisture content, particle size, or density variations in the material.

Feeder Speed Incorrect: Feeder speed is too high or too low.

Solutions:

Refill Hopper: Ensure the hopper is adequately filled with material.

Break Up Bridging: Use a poker or other tool to break up any bridging or arching in the hopper. Consider using a vibrator on the hopper.

Inspect Feeder: Check the feeder for damage, blockages, or worn parts. Repair or replace as needed.

Adjust Material: Adjust the moisture content, particle size, or density of the material to improve flowability.

Adjust Feeder Speed: Adjust the feeder speed to achieve a consistent and even flow of material.

Problem: Material clogging or jamming in the feeding system.

Possible Causes:

Excessive Moisture: Material is too wet and sticky.

Foreign Objects: Debris or contaminants in the material.

Feeder Design Inadequate: Feeder not suitable for the material being processed.

Build-up on Feeder Components: Material sticking to feeder walls and auger.

Solutions:

Dry Material: Dry the material before feeding it into the machine.

Remove Foreign Objects: Screen or filter the material to remove debris and contaminants.

Modify Feeder: Consider modifying the feeder design to improve flowability. Possible changes include increasing the auger pitch or adding a vibrator.

Clean Feeder Components: Regularly clean the feeder components to remove any build-up of material.

Problem: Briquettes are crumbling or weak.

Possible Causes:

Insufficient Pressure: Not enough pressure being applied to the material.

Incorrect Binder (if applicable): Binder is not suitable for the material or is not being added in the correct proportion.

Material Moisture Content Too Low: Material is too dry and does not bind together properly.

Die Wear: The die is worn and not forming the briquettes properly.

Material Composition: The material lacks inherent binding properties.

Incorrect Dwell Time: Not enough time for the material to consolidate.

Solutions:

Increase Pressure: Adjust the machine settings to increase the pressure applied to the material.

Adjust Binder: Experiment with different binders or adjust the amount of binder being added.

Increase Moisture Content: Add moisture to the material before pressing.

Replace Die: Replace the die if it is worn or damaged.

Change Material Composition: Add a component that enhances binding.

Increase Dwell Time: If the machine allows, increase the time the material is under pressure.

Problem: Briquetter overheats during operation.

Possible Causes:

Excessive Friction: Friction between the material and the die is generating heat.

Insufficient Cooling: The machine's cooling system is not functioning properly.

Overloading: The machine is being overloaded with material.

Hydraulic System Issues (if applicable): Low oil level, dirty oil, or pump malfunction.

Solutions:

Lubricate Die: Apply a lubricant to the die to reduce friction.

Check Cooling System: Inspect the cooling system for leaks, blockages, or pump failure. Repair or replace as needed.

Reduce Feed Rate: Decrease the material feed rate to prevent overloading.

Check Hydraulic System: Check the hydraulic oil level, filter, and pump. Replace the oil and filter if they are dirty. Repair or replace the pump if it is malfunctioning.

Problem: Briquetter is producing uneven or deformed briquettes.

Possible Causes:

Uneven Material Distribution: Material is not being evenly distributed in the die.

Die Damage: The die is damaged or worn unevenly.

Pressure Imbalance: Uneven pressure being applied to the material.

Inconsistent Material Feed: Fluctuations in the amount or density of fed material.

Solutions:

Improve Material Distribution: Ensure the material is being evenly distributed in the die. Adjust the feeding system or add a distribution plate.

Replace Die: Replace the die if it is damaged or worn unevenly.

Adjust Pressure: Adjust the machine settings to ensure even pressure is being applied to the material.

Stabilize Material Feed: Ensure a consistent flow of material into the die. Address any issues in the feeding system.

Problem: Low hydraulic pressure.

Possible Causes:

Low Oil Level: Insufficient hydraulic oil in the reservoir.

Pump Failure: The hydraulic pump is worn or damaged.

Leaking Hoses or Fittings: Hydraulic fluid is leaking from the system.

Valve Malfunction: A hydraulic valve is stuck or malfunctioning.

Dirty Oil Filter: Clogged filter restricting oil flow.

Solutions:

Add Hydraulic Oil: Add hydraulic oil to the reservoir to the proper level.

Replace Pump: Replace the hydraulic pump if it is worn or damaged.

Repair Leaks: Repair or replace any leaking hoses or fittings.

Repair Valve: Repair or replace any malfunctioning hydraulic valves.

Replace Oil Filter: Replace the hydraulic oil filter.

Problem: Hydraulic oil overheating.

Possible Causes:

Low Oil Level: Insufficient hydraulic oil in the reservoir.

Dirty Oil: Contaminated oil is causing excessive friction.

Restricted Oil Flow: Clogged filter or damaged hoses.Overloading the System: The hydraulic system is being overloaded.

Cooling System Malfunction: Hydraulic oil cooler is not functioning properly.

Solutions:

Add Hydraulic Oil: Add hydraulic oil to the reservoir to the proper level.

Change Hydraulic Oil: Replace the hydraulic oil with fresh, clean oil.

Replace Oil Filter: Replace the hydraulic oil filter.

Reduce Load: Reduce the load on the hydraulic system by decreasing the feed rate or pressure.

Repair Cooling System: Repair or replace the hydraulic oil cooler.

Problem: Frequent circuit breaker tripping.

Possible Causes:

Overload: The machine is drawing too much current.

Short Circuit: A short circuit is causing excessive current flow.

Faulty Wiring: Damaged or loose wiring is causing a short circuit.

Undersized Breaker: The breaker is not adequately rated for the machine's power draw.

Solutions:

Reduce Load: Reduce the load on the machine by decreasing the feed rate or pressure.

Inspect Wiring: Inspect the wiring for damage or loose connections. Repair or replace as needed.

Consult Electrician: Have an electrician inspect the electrical system and identify any short circuits or other electrical problems.

Upgrade Breaker: Replace the breaker with a larger one that is appropriately sized for the machine's power draw (consult an electrician).

Problem: Inconsistent motor speed or performance.

Possible Causes:

Voltage Fluctuations: Voltage fluctuations are affecting motor performance.

Worn Motor Components: Brushes, bearings, or windings are worn or damaged.

Faulty Motor Controller: The motor controller is malfunctioning.

Solutions:

Stabilize Voltage: Use a voltage regulator to stabilize the voltage supply to the motor.

Repair Motor: Repair or replace worn motor components.

Replace Controller: Replace the motor controller.

Regular Lubrication: Lubricate all moving parts according to the manufacturer's recommendations.

Regular Cleaning: Clean the machine regularly to remove dust, debris, and material build-up.

Inspect for Wear: Inspect all components for wear and tear and replace as needed.

Check Hydraulic Fluid Levels: Check the hydraulic fluid levels regularly and add fluid as needed.

Replace Filters: Replace filters regularly to ensure proper operation.

Tighten Fasteners: Check and tighten all fasteners regularly.

Train Operators: Properly train operators on the safe and efficient operation of the machine.

Important Considerations:

Safety First: Always disconnect the power supply before performing any maintenance or repairs.

Refer to Manual: Consult the machine's manual for specific instructions and recommendations.

Qualified Technicians: If you are not comfortable performing any of the troubleshooting steps described in this guide, consult a qualified technician.

Keep Records: Maintain accurate records of maintenance and repairs.

This guide provides general troubleshooting information. Specific issues may require further investigation and specialized knowledge. Always prioritize safety and consult the machine's manual and qualified technicians when needed.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com