-

Products

-

Application

A briquetting machine is a device used to compress loose biomass materials such as sawdust, straw, and paper into dense, solid blocks called briquettes. These briquettes can be burned as fuel, reducing waste and increasing the energy efficiency of heating systems. The process of making briquettes using a briquetting machine involves adding a binding agent to the loose materials and compressing them under high pressure to form a dense, solid block. The machines can be powered by electricity or manual labor, and come in a variety of sizes to suit different production needs.There are several types of briquetting machines, including:

A mechanical briquetting press is a machine used to compress and bind waste materials, such as wood chips, sawdust, or paper, into compact, solid blocks or briquettes. The process of briquetting is accomplished through the use of high pressure and heat, which causes the material to fuse together and bind. The resulting briquettes can be burned for fuel, used as a raw material in manufacturing, or disposed of in landfills, reducing waste and conserving resources.

A hydraulic briquetting press is a machine that uses hydraulic pressure to compress and bind waste materials, such as wood chips, sawdust, or paper, into dense, solid blocks or briquettes. This process is carried out through the use of a hydraulic cylinder that exerts a high level of pressure on the raw material, causing it to compress and bind together. The resulting briquettes can be used for fuel, as a raw material in manufacturing, or disposed of in landfills, reducing waste and conserving resources. Hydraulic briquetting presses are typically larger and more powerful than mechanical briquetting presses and are used in industrial and commercial settings.

A screw briquetting press is a machine that uses a screw mechanism to compress and bind waste materials, such as wood chips, sawdust, or paper, into dense, solid blocks or briquettes. The raw material is fed into the machine and pushed through a screw, which applies pressure and compacts the material into a solid briquette. The resulting briquettes can be used as fuel, as a raw material in manufacturing, or disposed of in landfills, reducing waste and conserving resources. Screw briquetting presses are commonly used in small to medium-sized operations and can handle a wide range of raw materials. They are considered to be a more efficient and cost-effective solution compared to other types of briquetting presses.

A punching briquetting press is a machine that uses a punching mechanism to compress and bind waste materials, such as wood chips, sawdust, or paper, into dense, solid blocks or briquettes. The raw material is fed into the machine and compacted by a punching mechanism that exerts high pressure on the material, causing it to bind together. The resulting briquettes can be used as fuel, as a raw material in manufacturing, or disposed of in landfills, reducing waste and conserving resources. Punching briquetting presses are commonly used for compacting and briquetting materials with a high moisture content or low density. They are typically smaller and more compact than other types of briquetting presses, making them suitable for use in small-scale operations.

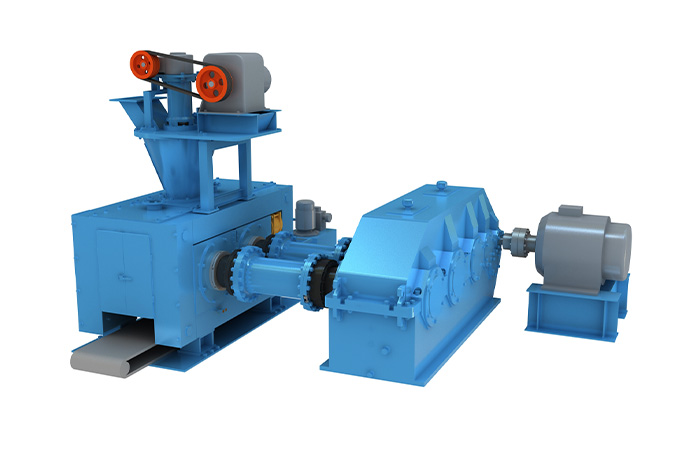

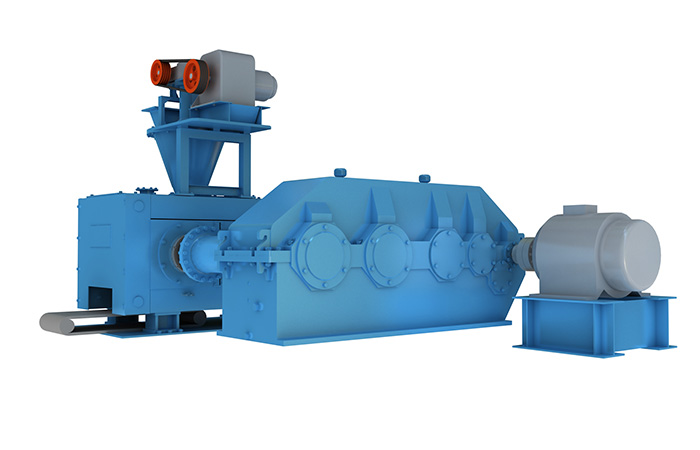

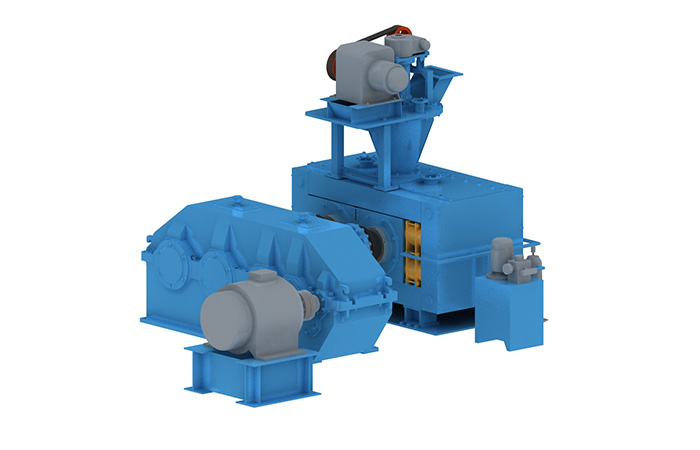

A roller briquetting press is a machine that uses a pair of counter-rotating rollers to compress and bind waste materials, such as wood chips, sawdust, or paper, into dense, solid blocks or briquettes. The raw material is fed into the machine and compressed by the rollers, which apply pressure and cause the material to bind together. The resulting briquettes can be used as fuel, as a raw material in manufacturing, or disposed of in landfills, reducing waste and conserving resources. Roller briquetting presses are commonly used in large-scale operations and can handle a wide range of raw materials with varying moisture levels and densities. They are known for their high production efficiency, low energy consumption, and long service life.

A biomass briquetting press is a machine that is used to compress and bind agricultural and forest waste, such as sawdust, straw, and other biomass materials, into dense, solid blocks or briquettes. This process is done through the use of high pressure and heat, which cause the material to fuse together and bind. The resulting briquettes can be burned for fuel or used as a raw material in manufacturing, reducing waste and conserving resources. Biomass briquetting presses are commonly used in rural areas to produce fuel from agricultural waste and help mitigate the problems associated with traditional fuel sources, such as deforestation and soil degradation. They are also becoming increasingly popular as a way to produce renewable energy, reduce greenhouse gas emissions, and promote sustainable development.

An agriculture waste briquetting machine is a machine that is used to compress and bind agricultural waste, such as straw, leaves, and other organic materials, into dense, solid blocks or briquettes. The process is carried out through the use of high pressure and heat, which cause the material to fuse together and bind. The resulting briquettes can be burned for fuel or used as a raw material in manufacturing, reducing waste and conserving resources. Agriculture waste briquetting machines are commonly used in rural areas to produce fuel from agricultural waste, reduce the amount of waste generated, and help mitigate environmental problems associated with traditional fuel sources. They can also play a role in promoting sustainable agriculture and rural development.

The choice of a briquetting machine depends on the type and size of material to be briquetted, as well as the production capacity required.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com