-

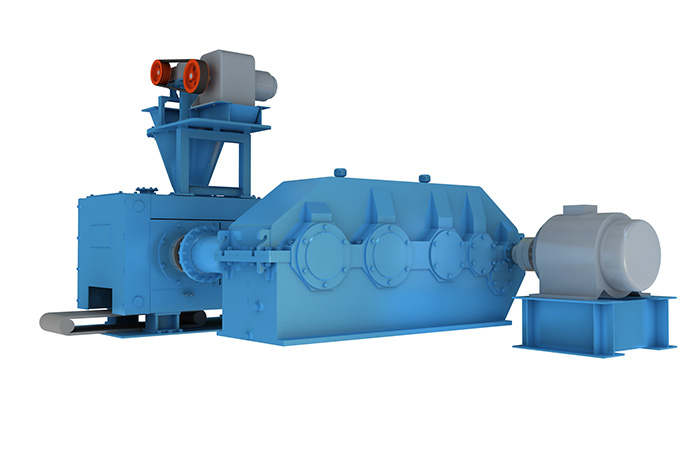

Products

-

Application

The briquetting machine has high operation efficiency, which can not only complete the production quickly, but also ensure the quality. In particular, the briquette briquette machine is related to the quality of the product, so it is necessary to eliminate unfavorable factors as much as possible for the working state of the briquette machine. In the long-term operation, the equipment of the briquetting machine will fail, and the briquetting machine may be blocked. What are the reasons for the blockage of the briquetting machine? Let's take a look together~

1. The cutting speed is too fast, so that the production speed is lower than the feeding speed, and it is easy to cause blockage.

2. If the temperature of the material is too high, the humidity will be too high. Once the humidity is too high, the viscosity will inevitably increase, so it is easy to cause the briquetting machine to be blocked.

3. The material is doped with larger particles, therefore, the material cannot pass through the roller, resulting in blockage.

4. The speed of the briquetting machine is too slow, and it is difficult to demould the material. Usually, the speed of the briquetting machine should be maintained at about 10 to 20 rpm.

5. Special mold design will also lead to the difficulty of mold release. For example, rectangle and diamond shape are special. Usually, we need oval and round shape, which is convenient for mold release.

6. The management of materials is not in place, mainly because the coordination and communication of employees are not in place, resulting in uneven delivery of materials.

1. No ball or no shape

In the use of briquetting machine equipment, sometimes the phenomenon of non-balling and non-forming occurs. The main reasons are insufficient feed, too low hydraulic pressure, soft roll skin quenching, and ball socket deformation. Insufficient feeding will make the briquetting machine without material to press, so add enough material to the briquetting machine; if the hydraulic pressure is too small, the material will not be fully pressurized. At this time, reduce the speed and increase the pressure. The deformation of the ball socket will make the shape of the material uneven, and it should be repaired or replaced in time.

2. Do not take off the ball

Due to the excessive moisture content of the raw material, insufficient pressure strength of the ball embryo, and rough surface of the new ball socket, it is possible to prevent the ball from falling off. At this time, the excess moisture in the raw material should be removed, and drying equipment should be used; The working pressure of the block machine and other equipment; remove the residue in the ball socket and ensure the smooth surface of the ball socket.

3. Ball and socket dislocation

The dislocation of the ball socket may be caused by the loose adjustment sleeve bolts or the loose fit of the roller skin and the shaft. You can adjust the grip of the briquetting machine and then tighten the bolts, or replace the roller skin bearings. You can also use processes such as regrinding after welding. deal with.

4. The oil pressure cannot be applied

When the equipment is running, sometimes the oil pressure cannot be applied. The cause of this problem may be the blockage of the oil suction port and the deformation of the sealing gasket at the connection. If the oil suction port is blocked, the cleaning work should be carried out in time to ensure the cleanliness of the equipment; If the gasket is deformed, the deformed gasket can be replaced with a new gasket, so as to ensure the normal operation and effective work of the equipment.

The above article summarizes the reasons for the blockage of the briquetting machine and the common faults of the briquetting machine in detail. I hope it can help everyone. If you have any other questions about the briquetting machine, please leave a message to us~

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com