-

Products

-

Application

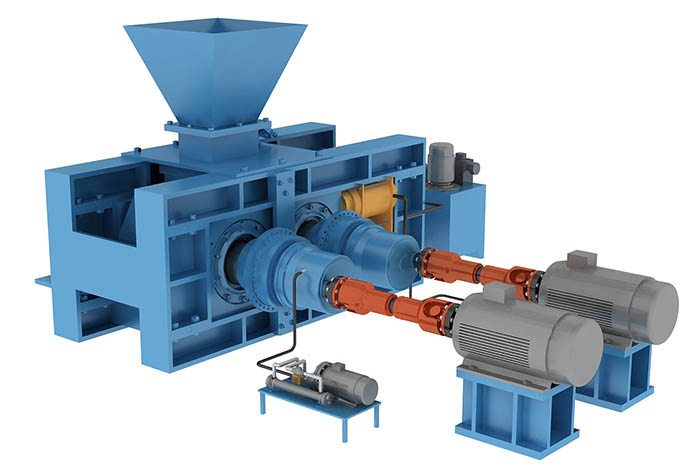

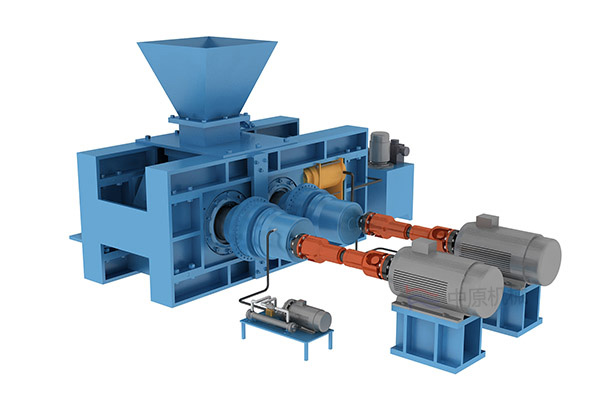

In terms of material crushing, the high-pressure roller mill has become a more effective material crushing and sand-making equipment since its introduction. It mainly relies on the pair of rollers to squeeze and crush the material particles. However, as the service life increases, the pressure of some high-pressure roller mills The system will show that the pressure is not maintained. What should I do if the high-pressure roller mill does not maintain the pressure?

The failure of the pressure holding function of the hydraulic system of the high-pressure roller mill is mainly manifested in the slow rise of pressure or no change at all when the system is pressurized, and the system pressure drops rapidly or gradually after the pressurization is stopped. The reasons for this phenomenon are generally as follows:

1. Leakage inside and outside the hydraulic cylinder

The internal leakage between the two chambers of the hydraulic cylinder of the high-pressure roller mill depends on the reliability of the piston sealing device. Generally, it is divided into: soft seal ring, hard cast iron piston ring seal, and gap seal according to reliability. Improving the manufacturing precision and matching precision of the hydraulic cylinder tube, piston and piston rod of the high-pressure roller mill will help reduce the failure of poor pressure holding caused by internal and external leakage.

2. Leakage of control valves

In the high-pressure roller mill, the reversing valve close to the hydraulic cylinder has a large leakage, resulting in no pressure holding. The leakage of the hydraulic valve depends on the structure and manufacturing accuracy of the valve. Therefore, using a poppet valve (such as a hydraulically controlled one-way valve) to maintain pressure is much better than a closed slide valve. In addition, the processing accuracy and matching accuracy of the valve core and the valve hole, the tightness of the sealing cone, etc. should be ensured, and the reasons for leakage caused by factors related to the manufacturing accuracy must be eliminated.

1. Replace the internal and external sealing components

Since the hydraulic system of the high-pressure roller mill has four hydraulic cylinders, after confirming the cause of the leakage in the hydraulic system, the hydraulic cylinders that have the internal leakage should be further confirmed, that is, the two hydraulic cylinders on the side of the pressure holding failure should be disassembled one by one. The hose joint connecting the cavity and the manifold block starts the hydraulic system to pressurize; if the hydraulic oil is sprayed out, it means that the leakage in the hydraulic cylinder has occurred. The hydraulic cylinder should be disassembled in time to check the sealing ring and cylinder body, and replace the Y-shaped seal Loop or repair the cylinder.

2. System pressurized oil supplement

When faced with working conditions that require a long time to maintain pressure, the method of replenishing oil can be adopted in the pressure holding process of the high-pressure roller mill to continuously compensate for the leakage of the hydraulic system. The main oil replenishment methods are as follows:

(1) The hydraulic oil pump is used to supply oil: Generally, the oil supply system of the variable pump is used. When working, the two pumps supply oil to the system together. The small flow oil pump (pressure holding pump) separately provides pressure oil to compensate for system leakage and achieve pressure holding. The pressure maintaining method of the oil pump continuing to supply oil can keep the working pressure of the oil cylinder stable.

(2) Use accumulators to supplement oil: generally use small bladder accumulators to communicate the high-pressure oil in the accumulator with the hydraulic cylinder of the high-pressure roller mill to compensate for oil leakage in the cylinder system. There is a one-way throttle valve at the outlet of the accumulator, its function is to prevent the sudden pressure release of the accumulator and cause shock when the reversing valve is switched.

This method can save power, keep the pressure for 24h, and the pressure drop does not exceed 0.1~0.2MPa. From the perspective of energy saving, the effect will be better if the electric contact pressure gauge, accumulator, hydraulic control check valve, main reversing valve control, etc. are used in combination.

Regarding what to do if the high-pressure roller mill does not hold pressure, the above are the specific reasons and solutions organized by the editor of Zhongyuan for everyone. I hope it can be helpful to everyone. Luoyang Zhongyuan Mining Machinery Manufacturing Co., Ltd., as a high-pressure roller mill manufacturer, has complete equipment processing and testing capabilities, and can independently manufacture and produce high-pressure roller mills. The quality is stable and reliable. If necessary, you can leave a message on our website. Or call the customer service phone for detailed consultation.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com