-

Products

-

Application

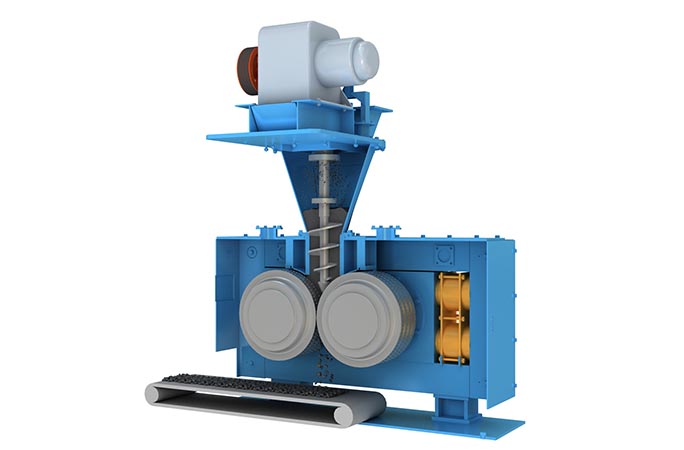

Modern industrial production pays attention to how to increase output while saving raw materials. Different industries have different efforts in making full use of raw materials. For coal mine-related industries, briquetting machines are essential to save raw materials and waste. Recycling equipment.

At present, briquetting machine manufacturers basically have multiple types of equipment for customers to choose from. Different types of briquetting machines have different production capacities. Some customers will choose to buy larger models of briquetting machines in order to more efficiently increase the output of briquetting machines. However, it is still impossible to effectively increase the output of briquetting machine, how to increase the output of briquetting machine has become the primary problem of many business operators.

No matter how high-capacity briquetting machine, if the quality does not meet the standard, the frequent failures in operation, then its production capacity must be unsatisfactory, but also affect the overall production volume and production quality, causing losses to the enterprise. Therefore, the purchase of briquetting machine should be made by a regular large brand manufacturer, and at the same time, check and maintain it before using it, and follow the standard operation.

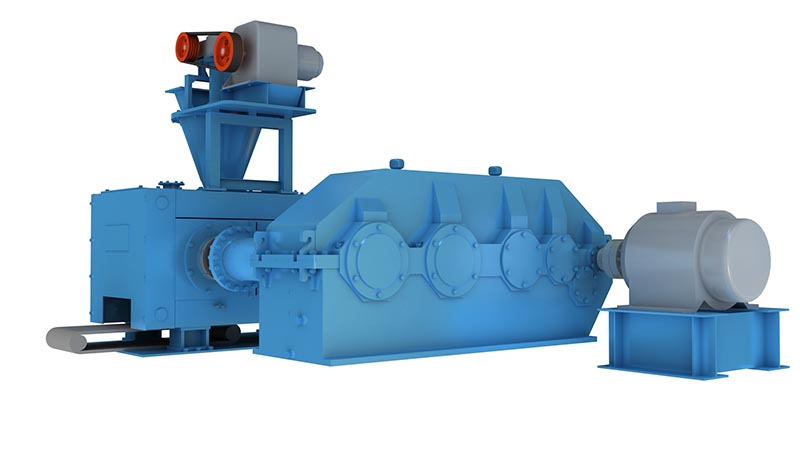

A high-capacity briquetting machine cannot complete large-scale production, so companies will build a ball press production line, and the production line is composed of many equipment. In addition to the briquetting machine, there are also crushers, conveyors, dryers, etc. The production capacity of other production line equipment must match the production capacity of the ball press machine, so as not to cause waste of equipment resources.

As we all know, the production line is a complete whole. Any equipment and personnel in it are an integral part of this whole. Any problem in the link will affect the output of this production line and even the safety of employees. Therefore, in the production process, you must ensure that each The performance and safety of the production line equipment, and at the same time to ensure fluency in each link, the results produced by each link must correspond to the beginning of the next link, so as to improve production efficiency.

The rotation speed of the counter-roller of the briquetting machine determines the speed of material forming, but the corresponding pressure should be given in place, otherwise it will affect the quality of the molding. This can only be done in the case of quality.

When choosing a briquetting machine, enterprise operators should purchase the corresponding models according to their own production conditions. Pursuing the capacity of the briquetting machine is undesirable, that is, the production efficiency of the briquetting machine cannot be improved, and a lot of money is wasted.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com