-

Products

-

Application

Winter is approaching. In the cold winter, many machinery and equipment will be affected to varying degrees, such as oil solidification and brittleness of rods. If you do not pay attention to heat preservation measures, equipment damage is likely to occur; and places that are too cold For example, equipment placed outdoors, although the equipment itself may have a certain degree of cold resistance, for users, cold protection can also avoid operating failures caused by operating stiffness.

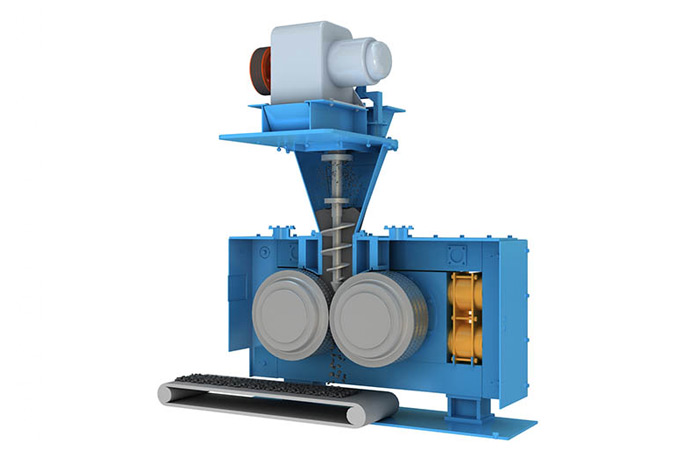

As a widely used material forming machinery and equipment, briquetting machine may appear in various indoor and outdoor environments. The use of briquetting machine in winter also requires various cold protection measures. The following briquetting machine manufacturers summarize a few points based on past experience Protective measures against cold for your reference.

For indoors, most factories are provided with heating, so the ball press equipment in the room only needs to ensure waterproof and prevent moisture from entering key parts. For ball presses used outdoors, we can cover the work area with a simple building with waterproof and snow release to prevent snow water from flowing into the equipment, and at the same time enclose the surrounding area to prevent cold wind from affecting the operation of the operator or material caused by wind Scattered and other situations.

If there are no heating measures in the briquetting machine production workshop and it is very cold, it may be that the temperature of the briquetting machine motor is too low, the voltage is not enough when starting, and it is difficult to start. Enclosures and heating facilities can be added around the motor to ensure that the motor is at normal operating temperature, so as to ensure that the ball press machine starts normally.

It should be noted that the heating facilities of the motor should be stopped in time, because the motor itself will emit a lot of heat when it is working. At this time, if the heating continues to cause the motor to overheat, damage or burn, etc.; at the same time, the temperature is too low. When starting down, a slow test run must be performed first. After the equipment generates heat due to work and the temperature has risen, no problems can be found before normal operation can be performed.

The heating and cold protection of the working environment can also help the operator to perform normal operations. Too cold will cause the body to become stiff, and it is inevitable that operating errors will occur. It is still a small matter to delay work efficiency. If the equipment is damaged due to operating errors, or even a production accident is a major event, so I suggest you don't be stingy with that little heating bill.

Mechanical equipment running at low temperatures requires the cold rigidity of its own parts. Generally speaking, the material of the briquetting machine is completely satisfactory, but it is not ruled out that some parts have internal defects that have not been detected when they leave the factory. After all, for mass production of parts, the inspection pass rate is difficult to achieve. This requires the ball press manufacturer to re-inspect the parts when assembling and installing the ball press to ensure that the ball press can adapt to cold conditions.

Whether it is winter or not, the use of machinery and equipment requires daily inspections, and the ball press is no exception. In winter, the ball press must be used in daily inspections. First, check whether the external parts have deformation or cracks caused by low temperature, and whether the oil of the night pressure system has solidified, and then listen to the operation of the equipment after starting up. The noise or special sound, then try to suppress it to see the work situation, and there is no problem before mass production can be carried out.

The use of ball presses in winter also requires materials. The pressing of some materials has certain requirements on humidity. If the temperature is too low, it may cause the moisture in the material to freeze and affect the pressing effect. Therefore, under the temperature of the working environment, it should be properly carried out during the material transportation process. Heat and keep warm, or perform a certain baking before pressing, but pay attention to the humidity of the material.

In addition to the above points, the use of briquetting machines in winter should also pay attention to safe production. Work in strict accordance with operating procedures and avoid various production accidents is more important. Therefore, we must provide employees with a good working environment in winter.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com