-

Products

-

Application

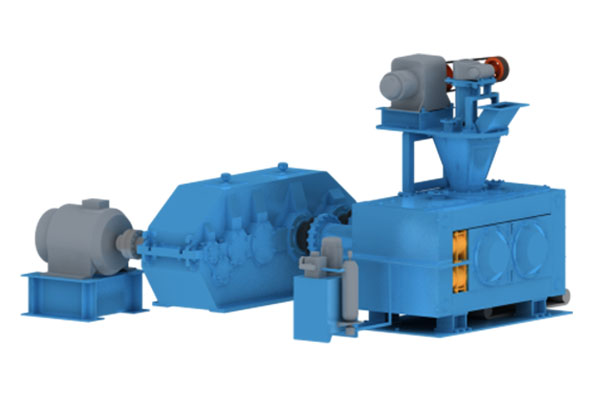

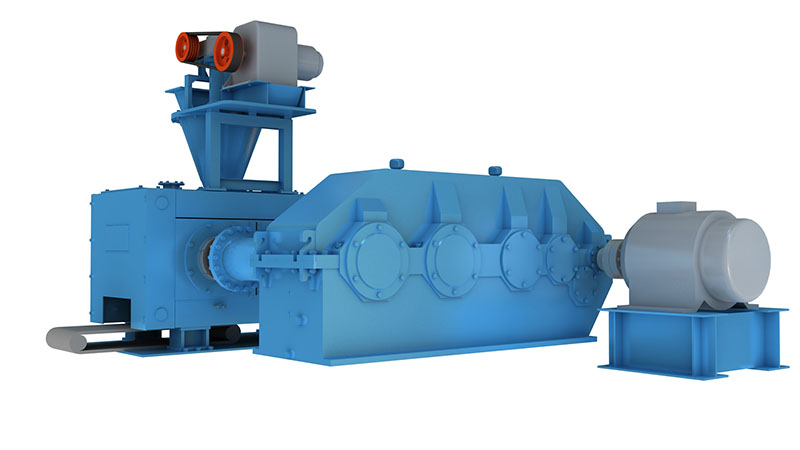

As a mechanical equipment for powder molding, the briquetting machine requires regular maintenance and preventive maintenance like other mechanical equipment. Some people don’t understand it. We know that regular maintenance can ensure the normal use of the briquetting machine and extend the use of the equipment. Life, what does this preventive maintenance mean? Why should the briquetting machine be repaired if there is no problem? To answer this question, you need to understand what is preventive maintenance of the briquetting machine.

There are two specific modes for the regular preventive maintenance of briquetting machine equipment. One is regular preventive maintenance, which is the shutdown and maintenance scheduled according to the equipment wear cycle plan of the briquetting machine; the second is condition maintenance, which is to monitor the state of the briquetting machine equipment and find that For hidden troubles or potential failures, timely maintenance should be arranged to eliminate the failures in the bud.

Another form of preventive maintenance of briquetting machine equipment is opportunistic maintenance. That is, preventive maintenance is performed during the off-season, holidays, weekends, or the opportunity of upstream and downstream downtime for maintenance. The "opportunity" of opportunistic maintenance can be to appropriately extend the maintenance period or to appropriately shorten the maintenance period. After demonstration, this extension or shortening will not cause major damage to the briquetting machine equipment.

No matter what preventive maintenance method is adopted, it is the treatment before the equipment failure of the briquetting machine is shut down, and the purpose is to avoid the occurrence of the failure.

Most of today's enterprises organize production according to orders, and customers have very strict requirements for delivery time. In lean production enterprises, punctuality and zero inventory have become typical characteristics. Once a production process is affected by the shutdown of the briquetting machine equipment, the order will be affected, which will greatly harm the efficiency and reputation of the company. Through preventive maintenance, it is of great significance to avoid a large number of unplanned downtime and ensure timely delivery.

The damage of the briquetting machine often starts from a part or a part, and this part or part affects other parts or parts, and it is transmitted step by step, causing big problems. This is the domino phenomenon of the system. Preventive maintenance can reduce or avoid minor damages, or eliminate small hidden dangers in time to prevent the impact from expanding and leading to more serious failures and damages.

Improper "preventive maintenance" will not only reduce costs, but also increase costs, which we call maintenance redundancy or over-maintenance. What we mean here is that proper preventive maintenance can reduce maintenance costs. Generally speaking, the efficiency of planned work is 3 to 4 times that of unplanned work.

Preventive maintenance because of its planned nature, you can study the repair plan in advance, prepare drawings, tools, spreaders and other auxiliary facilities materials, and prepare spare parts.

Once disassembled and repaired, the repair work can be completed efficiently. On the contrary, if it is after the maintenance, people diagnose the cause in the rush of a sudden shutdown, and then look for tools, spare parts, and materials. The real maintenance takes half a day, and the preliminary preparation may be one and a half to two days, and the time efficiency is significantly reduced. , The maintenance cost will naturally increase, coupled with the chain damage that may be caused by the subsequent maintenance, the replacement loss will also increase, and the maintenance cost will be even greater.

Preventive maintenance can eliminate local, minor or initial defects of the briquetting machine equipment, which can individually reduce the risk of safety accidents.

Many equipment will cause a large number of quality defects or scraps in the process of failure.

Opportunistic maintenance in preventive maintenance can make the factory's production plan, work schedule and resource allocation more reasonable, more planned, and more proactive. Some factories implement night-shift inspections, weekend inspections, and month-end inspections that take advantage of the opportunity to perform maintenance during the gap between the completion of production tasks.

The improper operation of briquetting machine equipment tends to increase friction and energy consumption. Preventive maintenance can ensure the smooth and stable operation of equipment and facilities, can effectively reduce energy consumption, and maintain the energy-saving effect of equipment.

It can be seen that the maintenance of the briquetting machine is an equipment protection measure that must be carried out at ordinary times, and the preventive maintenance of the briquetting machine can more ensure that the mechanical equipment does not have safety problems and emergencies, and it will not take up too much time. , Which not only guarantees safe and smooth production, but also guarantees the work efficiency of the enterprise, achieving two goals with one stone.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com