-

Products

-

Application

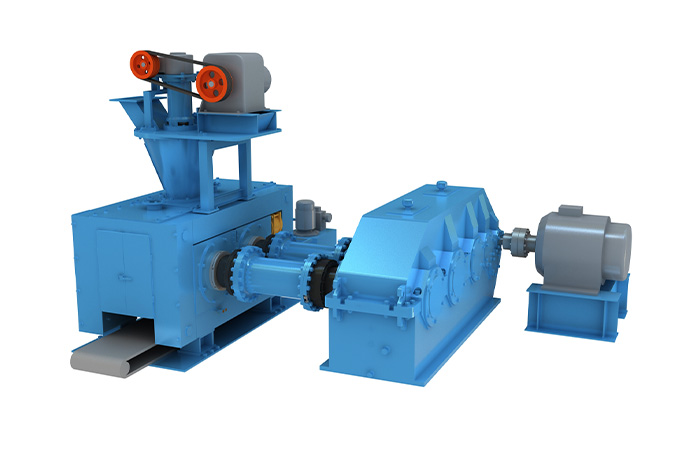

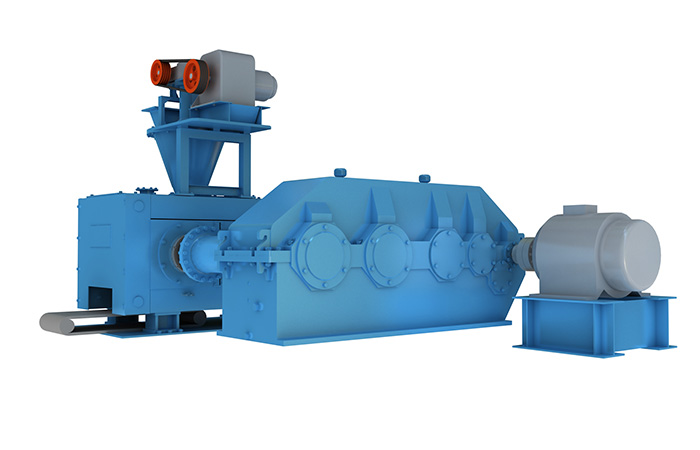

In modern industrial production, in order to save raw materials, various equipment in various industries emerge in an endless stream. As an important equipment for processing and reusing residual materials, briquetting machine will inevitably experience various wear and aging during use. Important working components in the briquetting machine Roller skins are often worn out and replaced.

The roller skin is a cylindrical component with ball sockets dug on the surface of the roller core of the ball press. Usually, the material is pressed by hydraulic drive rollers, which are formed by the ball sockets of the roller skin. As a very easy to wear ball press component, Frequent replacement is unacceptable for the operator, but the worn roller skin of the ball press cannot meet the production demand, and it is not enough if it is not replaced, so it is very important to maintain the roller skin during use. What is the maintenance method of the roller skin?

There are four installation methods for the roller skin of the ball press. Different ball presses use different methods, but the installation standards are the same. First of all, the installation of the roller skin cannot be dislocated. If the roller skin is already dislocated during installation, then Not to mention production, the shape of the ball socket on the roller skin must be aligned, otherwise the ball press will not produce balls, loose balls, and the spherical shape is not true. The edges of the nests wear each other, and the roller skins need to be replaced after a long time, which is not worth the loss.

The common steel for the roll skin of the casting ball press is 65 manganese alloy, and the common steel for the roll skin of the forging ball press is 92 chromium molybdenum. Our company uses a higher-level forging - bearing steel. Casting roller skins are relatively not wear-resistant, but the advantage is low cost. Some operators are not bad at money, and it is not a big deal to replace the roller skins frequently. However, for operators who use forged roller skins, the more durable the roller skins, the better. It is better not to replace it, but it is not necessary to maintain the roller skin of the ball press.

After the roller skin is installed correctly, in order to reduce the wear of the roller skin, certain protective measures must be taken before the equipment works. Magnets must be installed on the feeding belt conveyor to prevent the hard metal from entering the roller skin and causing the roller skin to tie. In the process of material transportation, the staff should pick out the stones in time, and ensure that the particle size of the material is below 3 mm, so as to ensure the service life of the roller skin and ensure that there will be no problems with the material forming; Before, the staff also checked the rollers of the ball press to see if there was any looseness or deviation. If there was such a phenomenon, continuing to work would easily cause the rollers to break, and the loss was not only the roller skin.

The hydraulic protection device is one of the cores of the briquetting machine. While providing the required production pressure for the rolls, it can also be caused by the overload of the hydraulic cylinder piston rod when too much material is fed between the roll skins or into the metal block. The resulting hydraulic pump stops and pressure changes make the accumulator act as a buffer, and at the same time, the relief valve opens to return the oil to make the piston rod displace, thereby increasing the gap between the two roller skins. no more serious damage.

In order for the hydraulic protection device to play its due role, it is necessary to carry out normal maintenance work on it. During work, the pressure supply of the hydraulic device should be reasonable, and the stroke should not be excessive. At the same time, it is necessary to ensure that the oil temperature of the hydraulic oil cannot be too high or too low. In normal times, the hydraulic oil should be filtered regularly. If there are impurities in the oil, it is easy to damage the seal. , causing the action to fail, and even the master cylinder will have scratches.

A clean production environment can enable employees to maintain a positive working attitude at work. Sanitary cleaning should be carried out after work every day. In addition to cleaning the ground, cleaning the equipment is also one of the maintenance methods for the roller skin of the ball press. There is too much dust. It is easy to cause dust accumulation on the moving parts of the equipment and the exposed parts of the bearings. If it is not cleaned for a long time, it will affect the safety and normal production, and also cause equipment damage; some materials pressed by the ball press are corrosive. When the equipment is cleaned, the remaining materials on the roller skin and in the ball socket should be cleaned up to prevent the roller skin from being corroded for a long time, thereby causing damage to the roller skin.

In the daily production of the enterprise, the maintenance method of the roller skin of the briquetting machine must be correct, in order to ensure that this wearing part of the briquetting machine is not so vulnerable, and the benefits of the enterprise will be increased in disguised form. It is one of the equipment maintenance methods that operators need to master one.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com