-

Products

-

Application

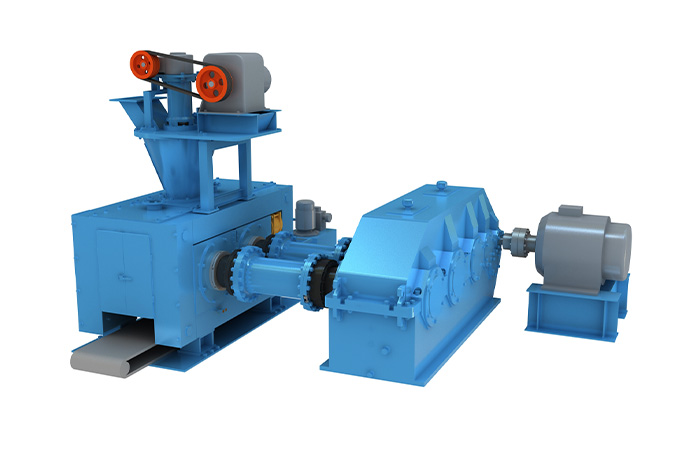

Most industrial production requires burning coal to obtain a high-temperature production environment. In order to improve the combustion performance of coal, briquette is basically used. The briquette can better meet the needs of industrial production in terms of strength and durability.

But not all the briquette pellets pressed by the briquetting machine can meet the requirements, and their performance is easily changed by the adjustment of the equipment parameters. How to measure the performance of the briquette machine?

Driven by the motor, the pair of rollers of the briquette briquetting machine rotate in opposite directions at the same speed. When the material falls between the two pairs of rollers, it begins to be compressed at the junction. At this time, the material is compressed in volume between the corresponding two ball sockets. ; The rollers rotate continuously, the ball socket is gradually closed, and the forming pressure gradually increases. When the distance between the two ball sockets is minimum, the forming pressure reaches the upper limit.

Then the rollers are rotated to gradually separate the ball sockets, and the molding pressure decreases rapidly. When the forming pressure is reduced to zero, the pressed briquette begins to expand and break away.

Randomly select 10 briquette pellets and place them on the particle strength testing machine one by one for pressure feed test, record the pressure value indicated when each briquette pellet cracks, and calculate the average value, the unit is N/ball. The average error is valid in the range of +50N, and the ambient temperature is 25 degrees Celsius.

Randomly collect 10 briquette pellets, bury them in an iron box containing clean fine sand (single-layer placement, 5 pellets each time), take them out immediately after 30 minutes of constant temperature at high temperature to measure their compressive value, and calculate the average value. The unit is N/ball.

10 briquette pellets were randomly selected and immersed in purified water at 25°C. After 2 hours, they were taken out to measure their cold strength, and the average value was taken, in N/ball.

The calorific value, sulfur content, chemical activity, slagging characteristics and ash melting properties of briquette pellets are measured according to relevant standards.

Regarding how to measure the performance of the pellets of the briquette machine, the above is the forming principle of the briquette machine and the method for measuring the performance of the pellets, which are organized and introduced by the briquette machine manufacturer. I hope it can be helpful to everyone.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com