-

Products

-

Application

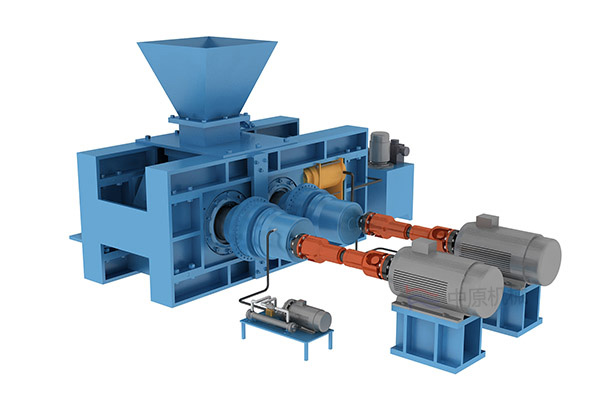

High pressure grinding rolls (HPGR) are a type of crushing equipment that are used in a variety of industries, including minerals processing, cement production, and waste management. They differ from other crushing equipment in several key ways:

Pressure

HPGRs apply a high level of pressure to the material being processed, which allows for finer particle size reduction and improved energy efficiency compared to other crushing equipment.

Mechanism

HPGRs use two counter-rotating rolls that are separated by a small gap, which creates a compressive force on the material as it is fed between the rolls. The material is then crushed and ground as it moves through the gap, producing a finer product.

Efficiency

HPGRs are highly energy-efficient compared to other crushing equipment, as they use less energy to produce the same amount of material. This is due to the high pressure and efficient grinding mechanism used by HPGRs.

Wear

HPGRs are designed to minimize wear and tear on the rolls and other components, which helps to extend the service life of the equipment.

Versatility

HPGRs can be used in a variety of applications, including hard rock crushing, coal preparation, and the processing of iron ore, copper ore, and other minerals.

In conclusion, the high pressure grinding rolls differ from other crushing equipment in terms of pressure, mechanism, efficiency, wear, and versatility. They offer a number of advantages over traditional crushing equipment, making them an attractive option for a wide range of applications.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com