-

Products

-

Application

For employees working on the factory floor, no matter how hard they are, no matter how tired they are, it is their job. The content of work cannot affect their working mood, and then affect their work quality. On the contrary, under the influence of some other external factors, it will affect the physical and mental health of employees. There is a lot of damage, one of which is the noise made by mechanical equipment, especially the noise of large-scale mechanical equipment.

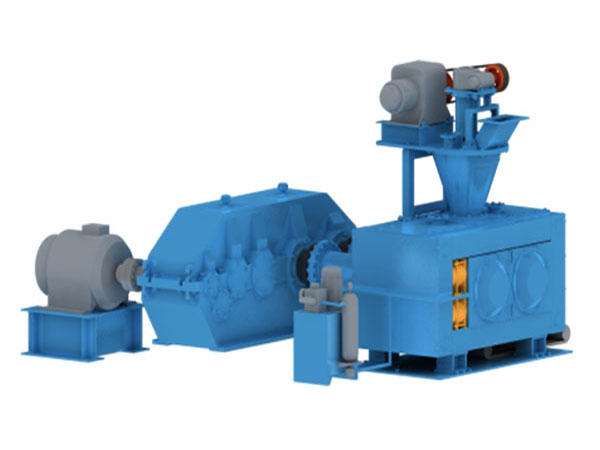

As a large-scale forming machinery and equipment, the ball press machine emits much louder noise than other small equipment. Under the influence of the noise of the ball press machine, the hearing and mood of the employees will deteriorate, and the corresponding work .The efficiency will definitely drop a lot, so how to reduce the noise of the ball press has become a problem that all operators need to solve.

For mechanical equipment such as briquetting machine, the noise source is nothing more than the friction sound of various parts, the sound of parts impact, the noise of gears, the noise of bearings, etc. To completely eliminate these noises is a idiotic dream, which is impossible to achieve, but it can be achieved through appropriate Way to reduce these noises.

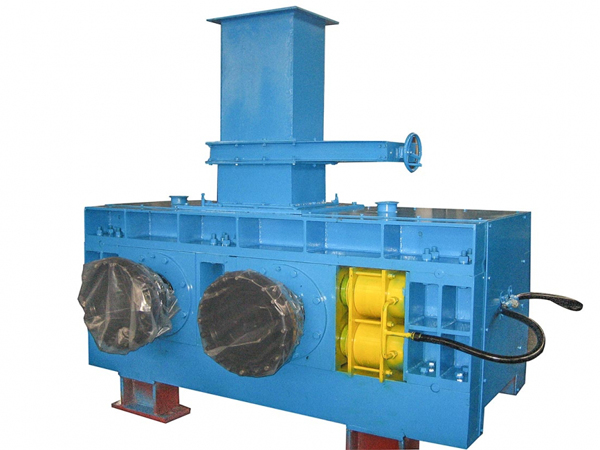

The briquetting machine, like other mechanical equipment, has component gaps. Because of the gaps between the components, the components collide with each other during work, which will generate noise. Anyone who understands mechanical fit knows that it is impossible to eliminate this kind of gap, but if we can reduce the gap, then the corresponding collision noise will be reduced.

To reduce the noise of the briquetting machine, a simple and rude way is to isolate some of the noise-producing parts, such as isolating the motor. In order to prevent the motor from overheating, the motor can be placed on the other side of the wall during installation. , And ensure smooth maintenance, in order to achieve the effect of sound insulation and noise reduction.

For the briquetting machine, the bearing is a part that runs through the entire equipment. If the bearing used is inferior, not to mention, the noise alone cannot meet the work requirements, so when choosing to buy the briquetting machine, be sure to confirm The bearings it uses are pros and cons. The bearing is a bit too long when it gets bigger. You only need to know that the bearings also have bottom noise bearings and silent bearings. You can choose equipment for bearings.

To sum up, when buying and installing a ball press machine, you must first choose a regular factory, such as the ball press machine produced by Luoyang Zhongyuan Mining Machinery Equipment Co., Ltd., which has fine workmanship, small gaps between components, and correspondingly low noise. Moreover, the installation workers of large factories are trained and guided, and the gap will be minimized during installation.

To reduce the noise of the ball press machine, it is not enough to reduce the noise of the equipment, because the work of the ball press machine is actually to process the materials in the entire production line, so noise reduction work should also be carried out during feeding. . For other equipment in the production line, we can deal with it in accordance with the noise reduction method of mechanical equipment, but other methods are needed during the feeding process.

After the material is crushed by the crusher, the size of the material is different. The large material is not stable enough in the transportation process, it will produce rolling displacement, and then make a louder sound. Therefore, it is necessary to select the large material and proceed to the second step. After the second crushing, enter the ball press equipment.

The collision and friction between the metal block and the conveying belt conveyor is also one of the sources of noise. Moreover, the metal block and other metal impurities enter the ball press directly without being selected, which will also cause damage to the roller skin. Rationale.

The feeding belt conveyor and feeding bearings should be maintained in time. If the noise of the bearing is less oily and worn, and the belt friction sound is emitted one after another, it can be regarded as "adding fire" to the entire working environment.

In addition to the urgent reduction of noise in the working area of the ball press equipment, noise reduction outside the working area is also very necessary. After all, an enterprise cannot have only one molding equipment assembly line, but there are still other office, transportation and storage areas.

Before installing the ball press, there are conditions that can be used to build a soundproof structure in advance to isolate the noise of the ball press inside the plant. At the same time, the soundproof wall can also absorb a certain amount of noise and reduce the volume.

If the plant and ball press equipment have been installed, asbestos and other sound insulation materials can be added to the walls of the plant to ensure that less sound sources radiate outside the working area.

Through the above points, it can be seen that the noise reduction of the briquetting machine must be targeted, and the noise of the machine cannot be completely eliminated, and it can only be reduced as much as possible. There is also need to ensure the tightness of the connections between the machines, and pay attention to proper maintenance. Zhongyuan Mine, the manufacturer of briquetting machine, reminds you that only by taking good care of the equipment can the equipment provide better service for us.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com