-

Products

-

Application

High pressure roller mill is a new type of grinding equipment developed on the basis of roller press for cement in recent years. Mines increase the specific surface area for fine grinding. The high pressure roller mill has the characteristics of high production efficiency, large crushing ratio, low power consumption, significant energy saving and convenient maintenance. For the operator of the high pressure roller mill, as long as the clinker can understand the working principle of the high pressure roller mill, the operation of the high pressure roller mill can be more handy, then do you know what the working principle of the high pressure roller mill is? What principles will be followed when it smashes materials?

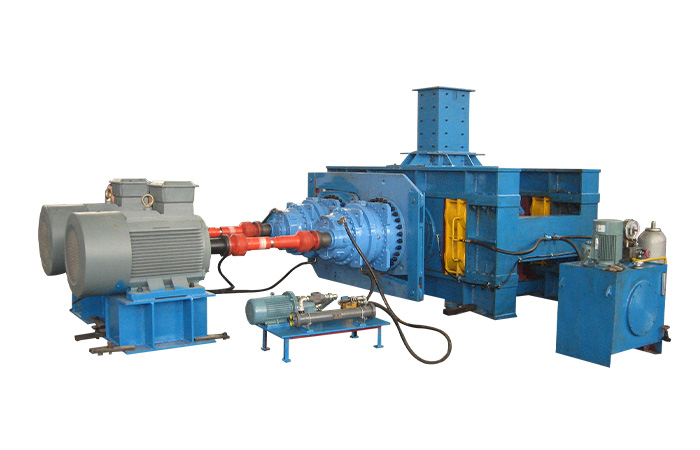

The high pressure roller mill is the same as the roller crusher in that there are two working rollers, but the working principles of the two are different. The high pressure roller mill is mainly composed of frame, extrusion roller, transmission device and feeding device. The squeezing roller is composed of a movable squeezing roller and a fixed squeezing roller, the two rollers have the same diameter, the axes are parallel to each other, and there is a certain gap between each other. When the high-pressure roller mill starts the motor, the roller shaft starts to rotate under the drive of the motor. At the same time, the movable roller is squeezed by the continuous thrust of the hydraulic cylinder, and the reaction force generated by the extrusion of the material acts on the fixed roller. Can rotate at the same speed and in the opposite direction. When the material falls between the two extrusion rollers from the feeding port, it is crushed by the two rollers and squeezed into a dense cake for discharge.

Compared with the traditional pulverization technology, the pulverization of the high-pressure roller mill is mostly quasi-static pressure pulverization. This pulverization method saves 30% energy consumption compared with the impact pulverization method, and the high-pressure roller mill can also pulverize the material layer.

When the high-pressure roller mill is working, the feeding material enters the crushing cavity between the two rollers of the high-pressure roller mill through the feeder with adjustable opening size, and the material is crowded and fed. Under the double action, the incoming material is forcibly squeezed into the continuously compressed crushing cavity and compacted, and when it reaches a certain pressure, it is crushed, and finally a dense but crack-filled flaky cake product is discharged. There are a large number of fine particles, micro-fine particles and micro-cracks in the material cake, which makes the mechanical strength of the material cake very low, and indirectly improves the processing capacity and grinding efficiency of the mill. This kind of mutual crushing between materials can make the crushing efficiency higher, and at the same time can reduce the wear of the high pressure roller mill.

After understanding the working principle of the high-pressure roller mill, we can also easily understand the application range of this equipment. According to its working characteristics, the high-pressure roller mill can be used for medium, fine and ultra-fine grinding of loose materials; when When used in the beneficiation industry, the high pressure roller mill can be used as a pre-grinding equipment, and can also be used in conjunction with a ball mill.

The above is the relevant introduction of the working principle of the high pressure roller mill. In order to ensure the processing quality and work efficiency of the high pressure roller mill, it is recommended that you purchase a high pressure roller mill with better quality. The high-pressure roller mill produced by our company is of excellent quality, good performance and stable operation. Customers in need are welcome to inquire and order.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com