-

Products

-

Application

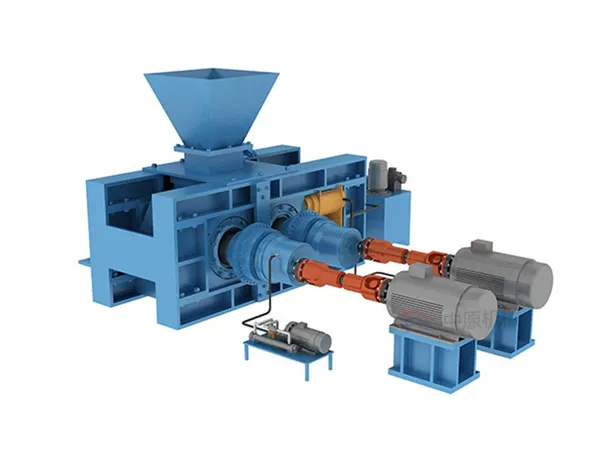

High-Pressure Grinding Rolls

Compound Crusher

Jaw Crusher

Single Tooth-Roller Crusher

Double Teeth-Roller Crusher

Screening Typed Double Teeth Roller Crusher

Four Teeth-Roller Crusher

Double Plain-Roller Crusher

Four Roller Crusher

Impact Crusher

Reversible Impact Hammer Crusher

Hammer Crusher

Ring Hammer Crusher

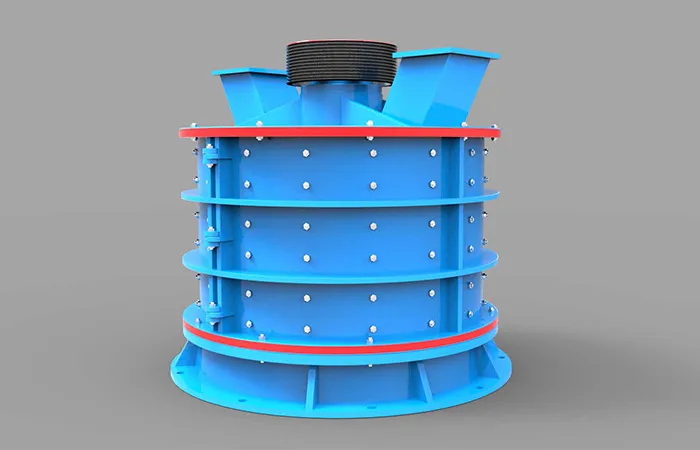

Vertical Compound Crusher

Vertical Shaft Hammer Crusher

Hammerhead, plate hammer, stationary jaw plate, swing jaw plate, impact liner, liner and sieve plate are common wear parts of jaw crusher,impact crusher and hammer crusher.Adopting metamorphic high-manganese steel, they are shaped, casted, sand-cleaned, heat-treated, and added with a composite modifier to perform graded composite modification of molten steel, which is to improve carbide morphology, reduce inclusions, purify molten steel, refine grains,stable alloying elements and prolong the service life.

Tooth roller, toothed plate, plain roller, tooth crown and grizzly bar are made of ZG20SiMn.They are processed by multiple procedures such as turning, milling, drilling and grinding. According to different crushed materials, the wear-resistant welding rods of different properties can be surfaced to prolong the service life.Wear-resistant layer could be welded repeatedly to save cost.

The elastic support is used for roller crusher and is assembled by base,tie rod, springs, etc. Its function is to apply sufficient pressure to adjust the distance between the rollers, which can play a safety protection role.

The toothed roller or smooth roller assembly is the main part of roller crusher and is assembled by the main shaft, roller hub,roller shell, bearing,bearing seat and the corresponding sealing units.The material of ZG20SiMn is adopted for roller shell body.For different crushing materials, different types of wear-resistant electrodes are used for surface welding. After the surface of the roller shell is worn, it can be repaired by surface welding again, which prolongs the service life of roller shell.

The movable jaw assembly is the main part of jaw crusher. It is mainly assembled by pulleys, flywheels, movable jaw, movable jaw plate, and bearings. The jaw plate is made of high-manganese steel. According to different crushing materials, some other chemical elements are added on the basis of high-manganese steel, which greatly improves the service life of the jaw plate.

The rotor assembly is the core part of the rotor crusher. It is assembled from the main shaft, rotor, plate hammer, bearing, bearing seat and corresponding seals. The plate hammer is made of high-manganese steel.According to different crushing materials, some other chemical elements are added on the basis of high-manganese steel, which greatly improves the service life of the plate hammer.

The roller shell is made of bearing steel and is processed by multiple procedures such as turning, flaw detection, milling and heat treatment. The surface hardness can reach above HRC58.The surface of the roller shell is inlaid with tungsten carbide studs, which also improves the service life while ensuring the crushing size.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com